Composite labeling device of explosive production line barcode and RFID (Radio Frequency Identification Device) and labeling method

A production line and barcode technology, applied in labeling machines, labels, packaging, etc., can solve problems such as unfavorable production safety and difficulty in reducing workshop capacity, and achieve the effects of improving production safety, reducing workshop capacity, and improving management efficiency and level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

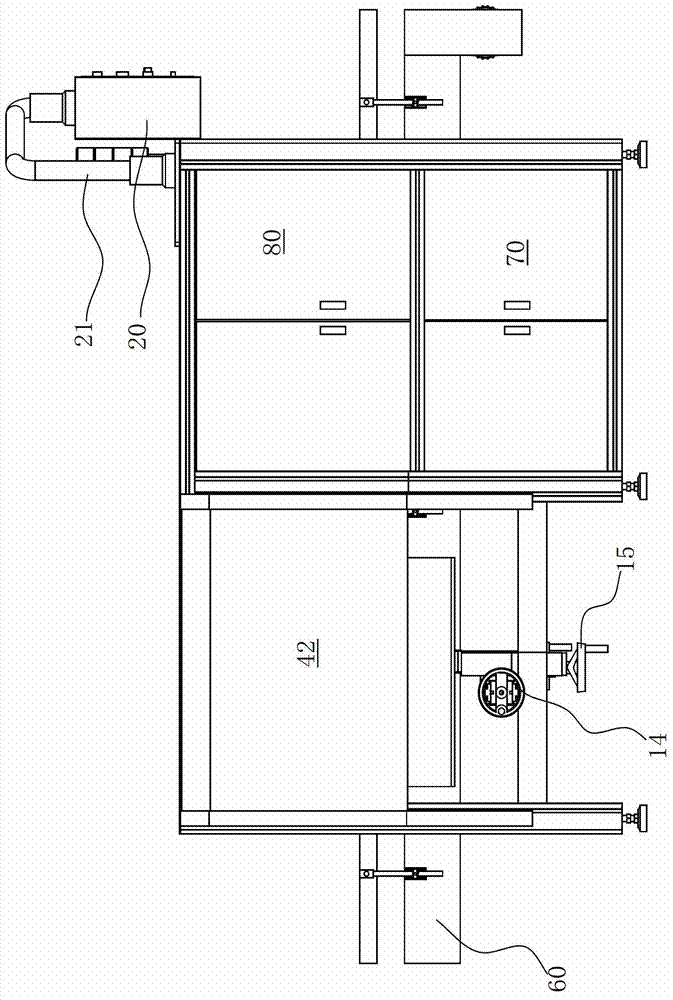

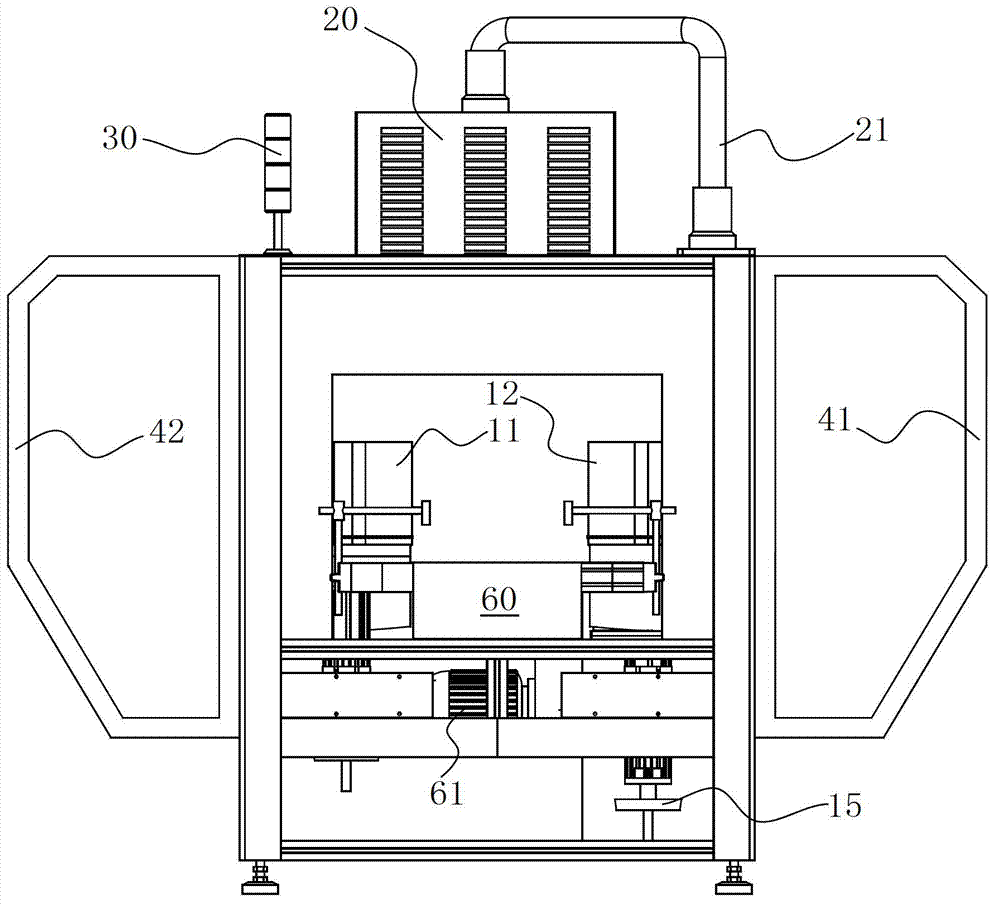

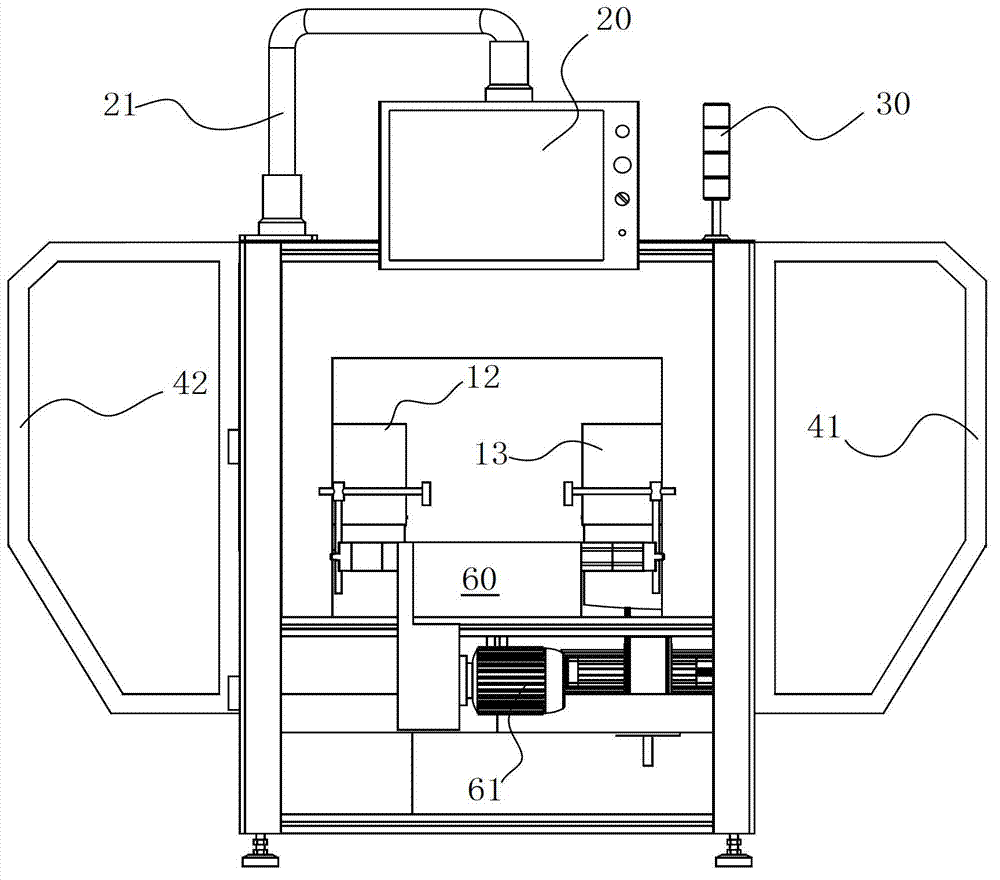

[0025] Such as Figure 1 to 4 The shown explosive production line code and RFID composite labeling equipment includes a metal chain plate structure conveyor line 60, which is driven by an explosion-proof motor 61 and has a frequency converter. The conveying speed is usually adjusted at 8-12 boxes per minute. The left and right sides of the conveyor line 60 are provided with a bar code instant labeling and labeling machine 11 and 12 respectively. The two code instant labeling and labeling machines 11 and 12 are arranged opposite to each other, and are used to label the two opposite sides of the packing box with bar codes. Two image-based barcode scanners are arranged at the downstream positions of the bar code instant labeling and labeling machines 11 and 12, that is, in the forward direction of the conveying line 60. The image-based barcode scanners are arranged on both sides of the conveying line 60 and arranged opposite each other. It is used to scan the barcode that the barc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com