Spiral pipe bender for multi-station energy saving strip lamp

An energy-saving lamp and multi-station technology, applied in the direction of manufacturing tools, glass molding, glass reshaping, etc., can solve the problems of slow heating speed, large heat loss, and unstable temperature, so as to reduce heat loss and save The effect of energy consumption and guaranteed heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

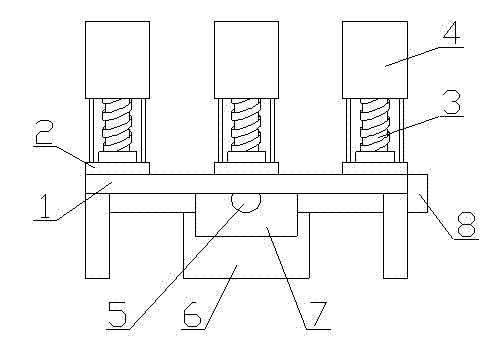

[0010] Such as figure 1 As shown, the multi-station energy-saving lamp tube spiral pipe bending machine of the present invention includes a machine table (1), and six bases (2) are arranged equidistantly on the machine table (1), and the bases (2) On the top, a spiral mold (3) is vertically provided, and the electric heating package (4) is covered with the electric heating package (4), and the lower end of the electric heating package (4) is fixedly connected to the base (2), and the spiral mold The lower end of (3) is hingedly connected to the rotating shaft (5), the rotating shaft (5) is also connected to the motor (6) and the reducer (7), and a control switch (8) is provided on one side of the machine (1). The middle of the electric heating pack (4) is designed as a hollow cylinder, which generates heat when energized.

[0011] When the present invention is working, the lamp tube to be processed is placed in the spiral mold (3), heated evenly and efficiently by the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com