Combined stress foundation-less steel concrete retaining wall

A technology for retaining walls and stressed steel bars, which is applied in the field of retaining walls, can solve the problems of large frame column cross-section and reinforcement, distortion of seismic calculation results of the upper layer of the frame, etc., to achieve convenient construction, save foundation treatment costs, and overall stress real and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through specific embodiments and accompanying drawings.

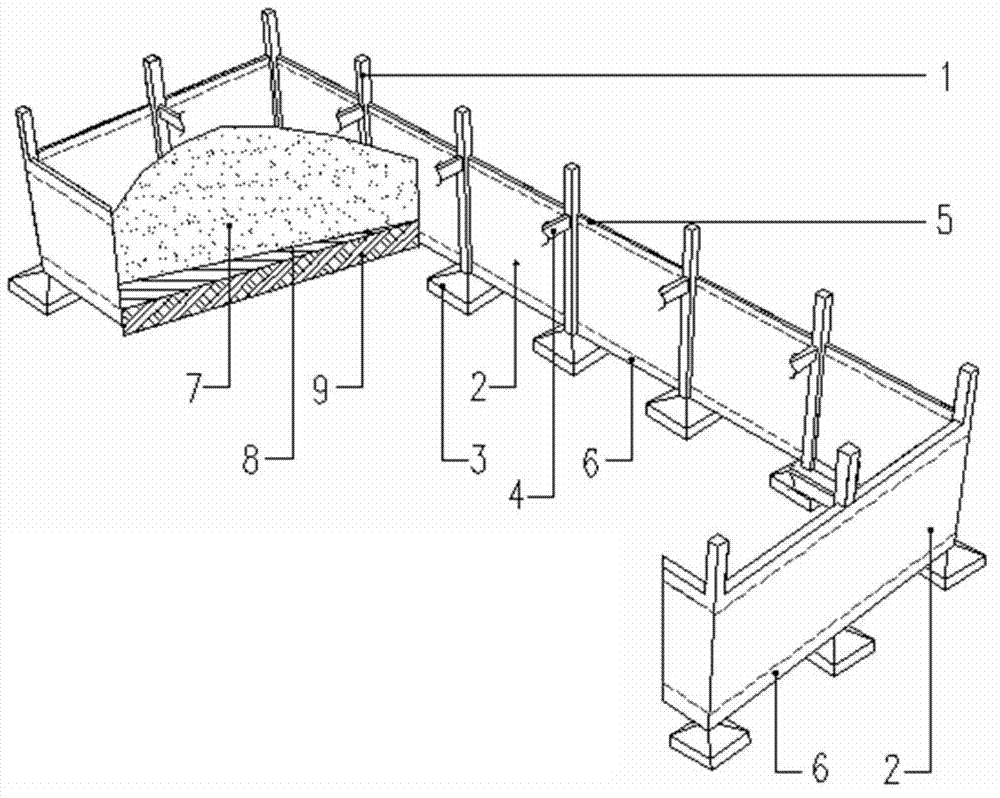

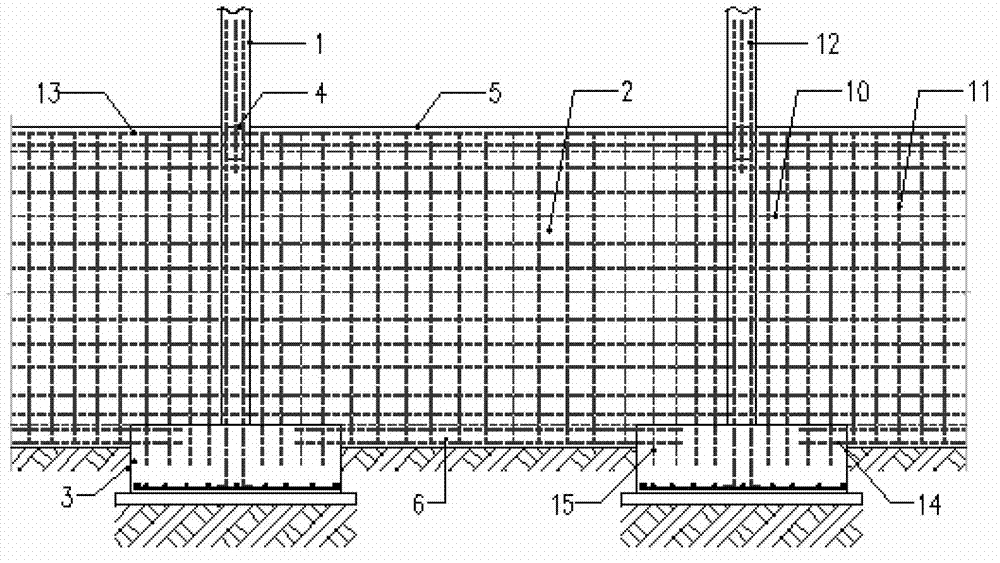

[0023] figure 1 It is a schematic diagram of the frame model of the combined force-bearing steel concrete retaining wall without foundation in this embodiment, figure 2 Schematic diagram of reinforcement configuration for the retaining wall.

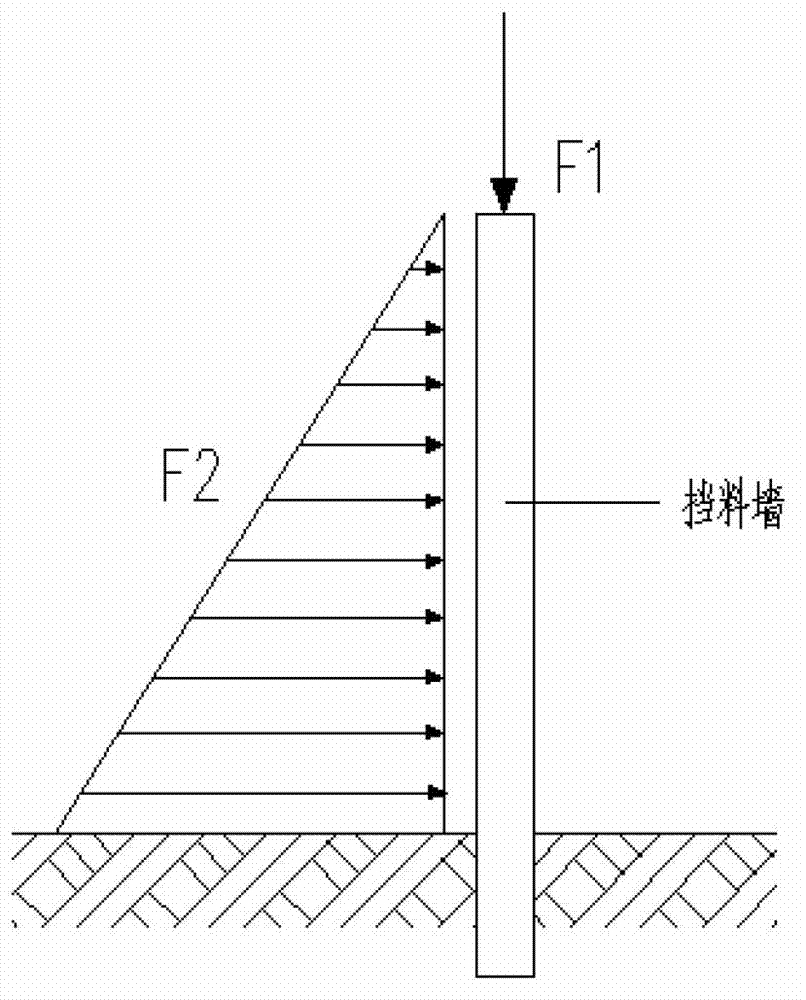

[0024] like figure 1 and figure 2 As shown, the reinforced concrete retaining wall 2 is poured together with the frame column 1 of the reinforced concrete frame of the factory building. The upper concealed beam 5 and the lower concealed beam 6 are arranged inside the reinforced concrete retaining wall 2 , and the stressed steel bars 13 in the concealed beam penetrate through the frame column 1 in the horizontal direction. The frame foundation 3 is used to support the frame column 1 and is poured together with the lower hidden beam 6 . The horizontal stress bars 14 of the lower hidden beam 6 and the vertical stress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap