Clamping device for connection

A clamping device and fastening technology, applied in the direction of hose connection device, connecting member, friction clamping detachable fastener, etc., can solve the problems of product deviation, product quality obstacle, lack of availability, etc. Increased productivity, reliable quality management, and the effect of not complicating the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] [Structure of Embodiment 1]

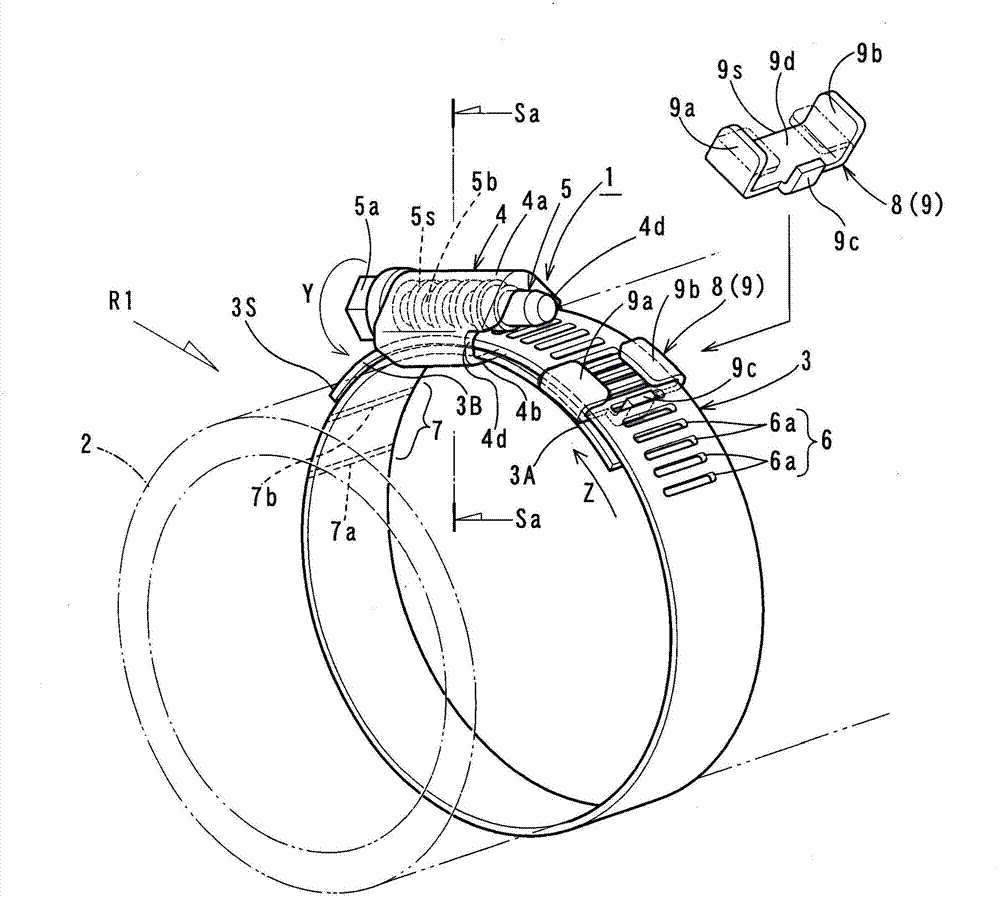

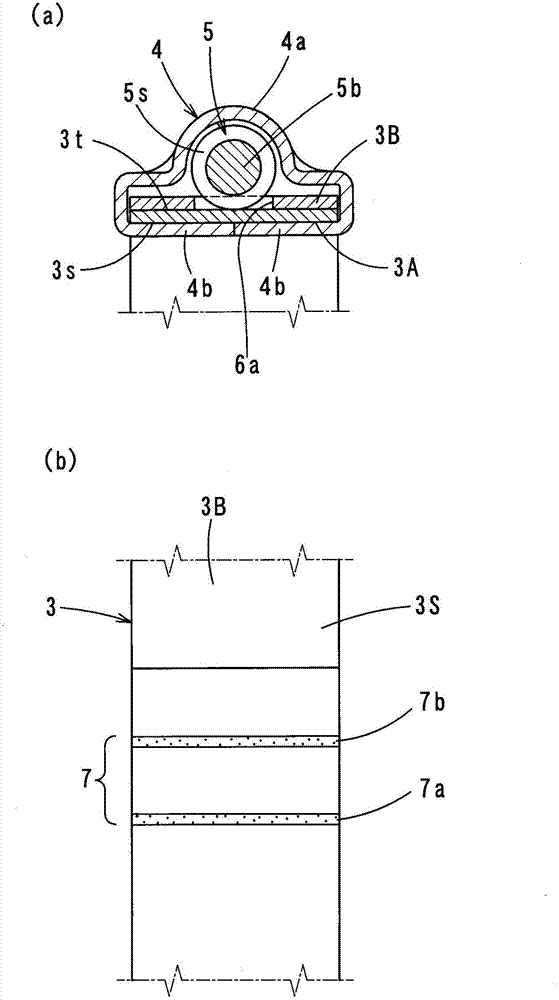

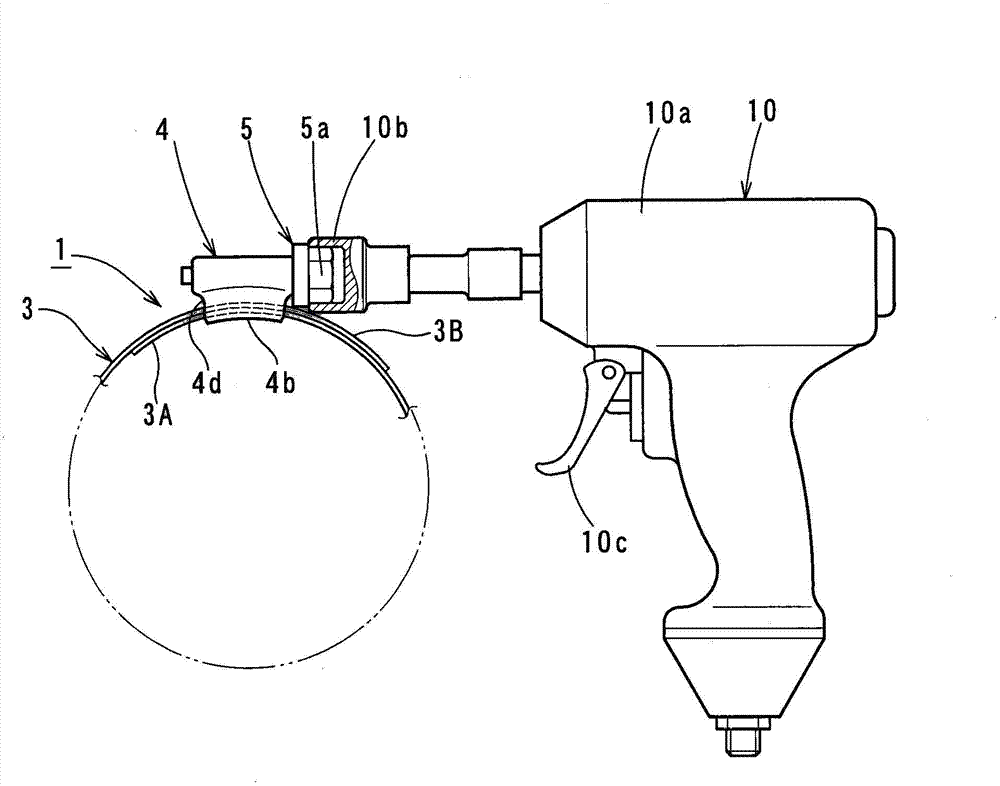

[0091] based on Figure 1 to Figure 4 Embodiment 1 of the present invention will be described.

[0092] figure 1 The clamping device 1 for connection in is especially suitable for the case where the fastened part 2 such as a hose requires a large surface pressure fastening force, for example, for an engine with a supercharger (not shown), it is suitable for A case where an intercooler for cooling compressed air is connected to an intake pipe (both are not shown) to increase the filling rate of air. Hereinafter, the tightening force and the tightening force of the fastened portion 2 are used in the same meaning.

[0093] The clamping device 1 for connection includes an end-ring-shaped fastening belt 3 for fastening around the fastened portion 2 . The fastening band 3 is formed into a belt shape having a desired width and length, for example, from an elastic material such as a SUS304-based stainless steel plate.

[0094] For example, if ...

Embodiment 2

[0119] Figure 5 (a), Figure 5 (b) shows Example 2 of the present invention. The difference between Embodiment 2 and Embodiment 1 is that first notch grooves 9E are formed on both sides of the main body part 9d at one end part 9s of the blocking member 8, and second notches are formed at the bent parts 9a and 9b. Slot 9F (refer to Figure 5 (a)).

[0120] When the bent portions 9a, 9b of the rectangular plate 9 are crimped to the other end side 3B, the first notch groove 9E overlaps the second notch groove 9F, and the communication groove 9G is formed as a notch-shaped slit (see Figure 5 (b)). Then, when the tightening of the fastening tape 3 ends, as Figure 5 As shown by the dashed-dotted line in (b), the opening edge portion 4 d of the casing 4 meets and engages with the communication groove 9G as an engaged portion. In addition, the gap shape of the tooth portion 6a in the fastening belt 3 and the front end shape of the flange portion 9c may be set to be the same, ...

Embodiment 3

[0128] Figure 6 to Figure 8 Example 3 of the present invention is shown. Embodiment 3 differs from Embodiment 1 in that the stopper 8 is configured to also serve as the crushing member 13 .

[0129] Such as Image 6 As shown in (a), the rectangular plate 9 as the stopper 8 is formed with an oblong through-hole 9f from one bent portion 9a to the main body 9d, and an oblong through-hole 9g is formed from the other bent portion 9b to the main body 9d. .

[0130] The main part 9d of the rectangular plate 9 is formed with a small circular hole 9h as a hole and oblong holes 9j and 9k on both sides of the small circular hole 9h, and is hollowed out to reduce the size.

[0131] In the rectangular plate 9, one end portion 9s on the opposite side to the flange portion 9c also serves as a stopper portion 8A. In addition, in the rectangular plate 9, the arrangement area of the through holes 9f, 9g, the small circular holes 9h, and the oblong holes 9j, 9k is defined as the plastic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com