Secondary optical element used for light-emitting diode (LED) illumination

A secondary optical element, LED lighting technology, applied in the field of optics, can solve the problems of expensive manufacturing cost of aspherical lenses, poor uniformity of illumination, large volume of aspherical lenses, etc., to reduce or eliminate glare effects, improve Brightness, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

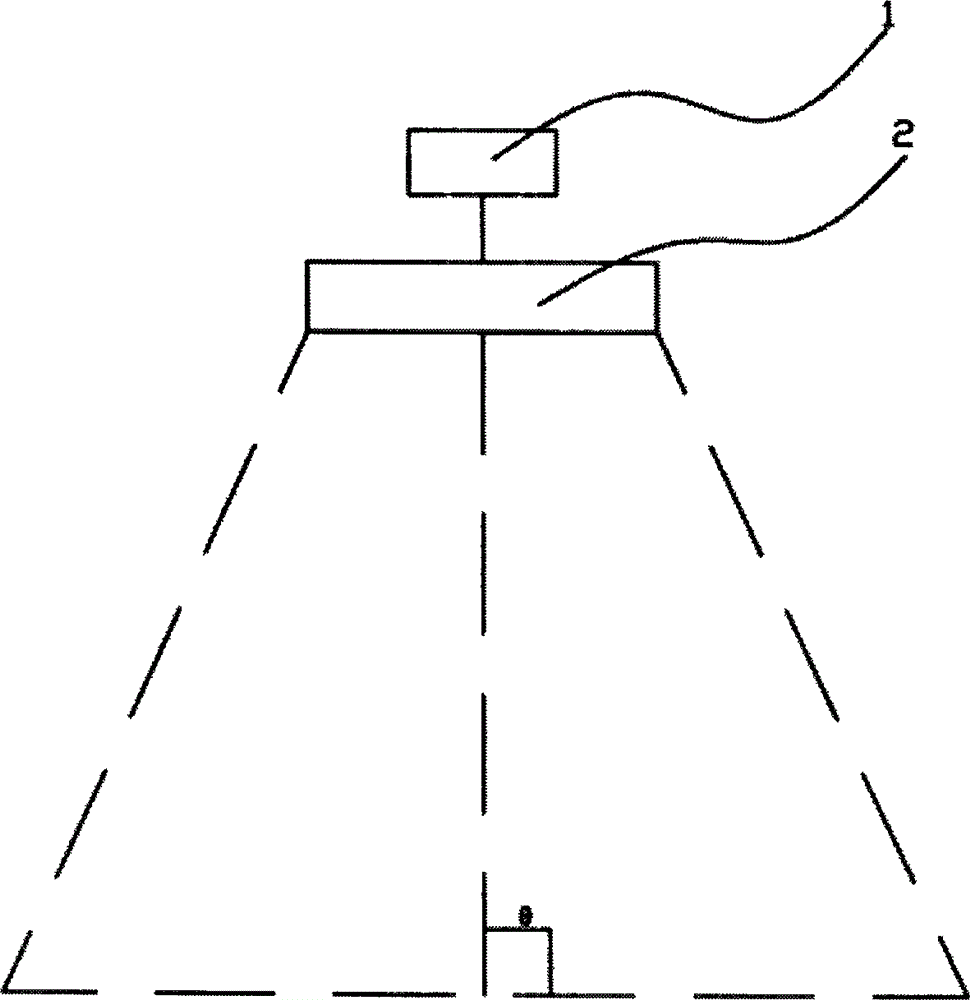

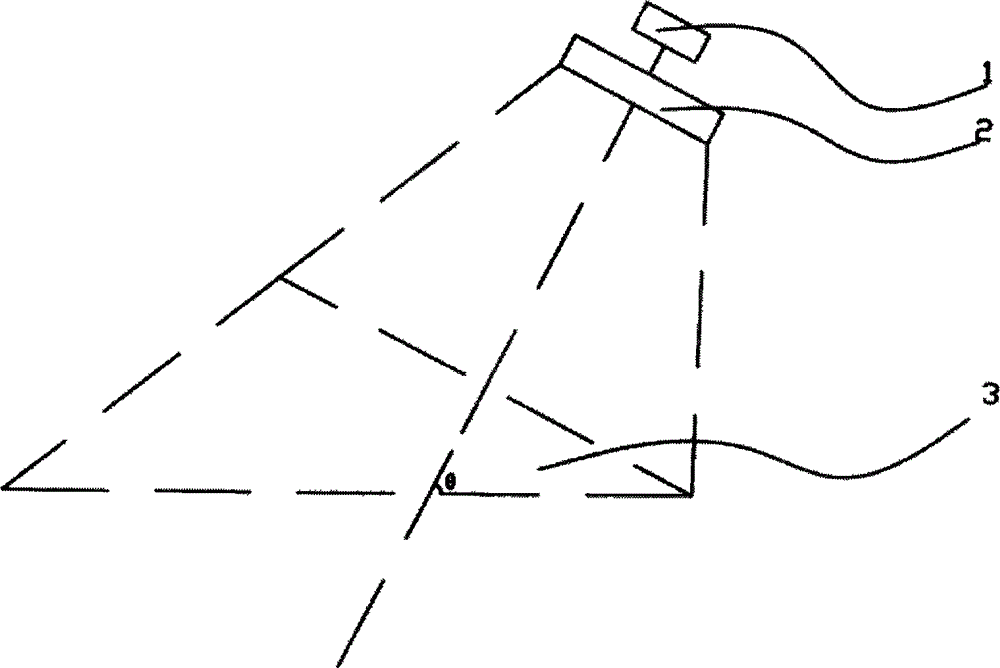

[0015] The invention discloses a secondary optical element for LED lighting, which includes an LED1 and a secondary optical element, the secondary optical element is a micro-diffraction optical element 2 . The micro-diffraction optical element 2 relies on the diffraction of light to control the direction of light, which can improve the uniformity of light intensity on the surface to be illuminated, improve the brightness of illumination, and can also suppress the luminous intensity at certain angles, thereby eliminating the glare effect, and is small in size. It is easy to manufacture and has a large tolerance for processing errors.

[0016] In a specific embodiment of the present invention, the LED1 is applied to a table lamp or a street lamp or a photolithography machine. The vertical distance z between the micro diffractive optical element 2 and LED1 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com