Homogenizing element for dmd digital lithography system and its design method

A lithography system and design method technology, applied in the field of digital lithography, can solve the problems of backward development of lithography data processing software for high-speed drive boards, lack of efficient light uniform components, and influence on light uniformity effects, etc., to achieve light energy reflection and Less refraction loss, improved uniform light effect, improved uniformity of light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

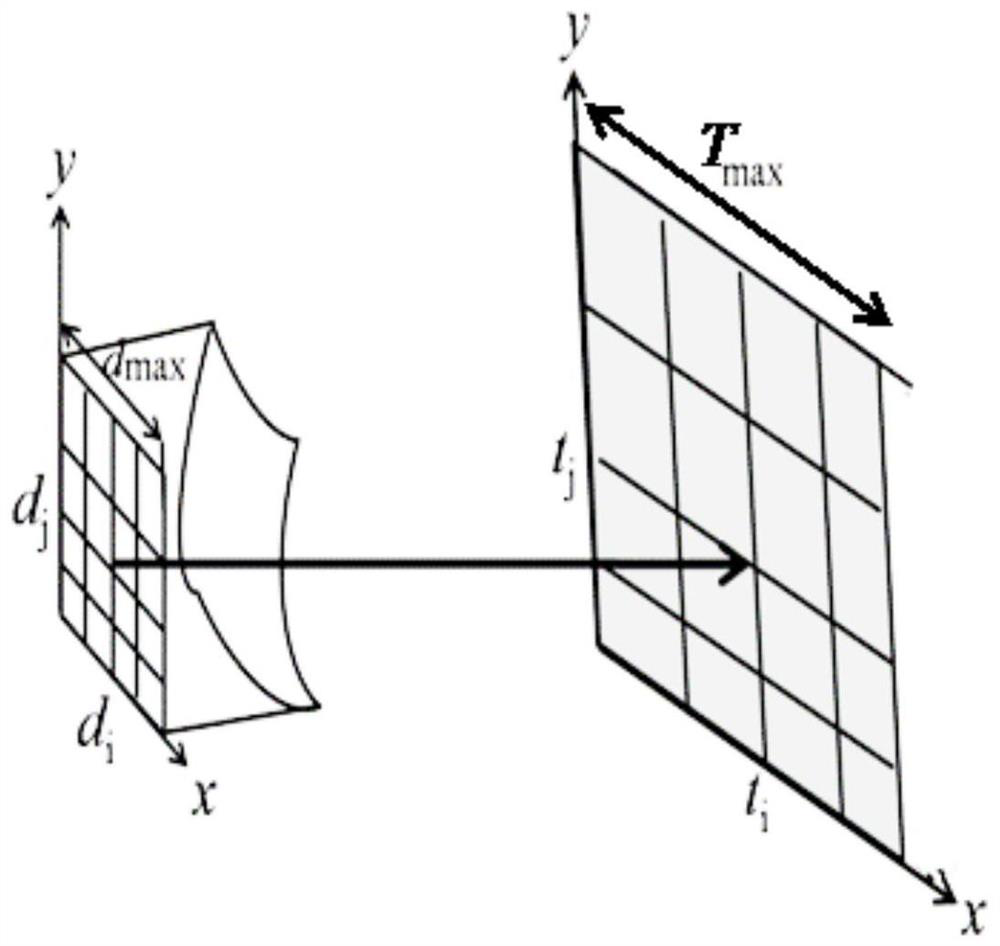

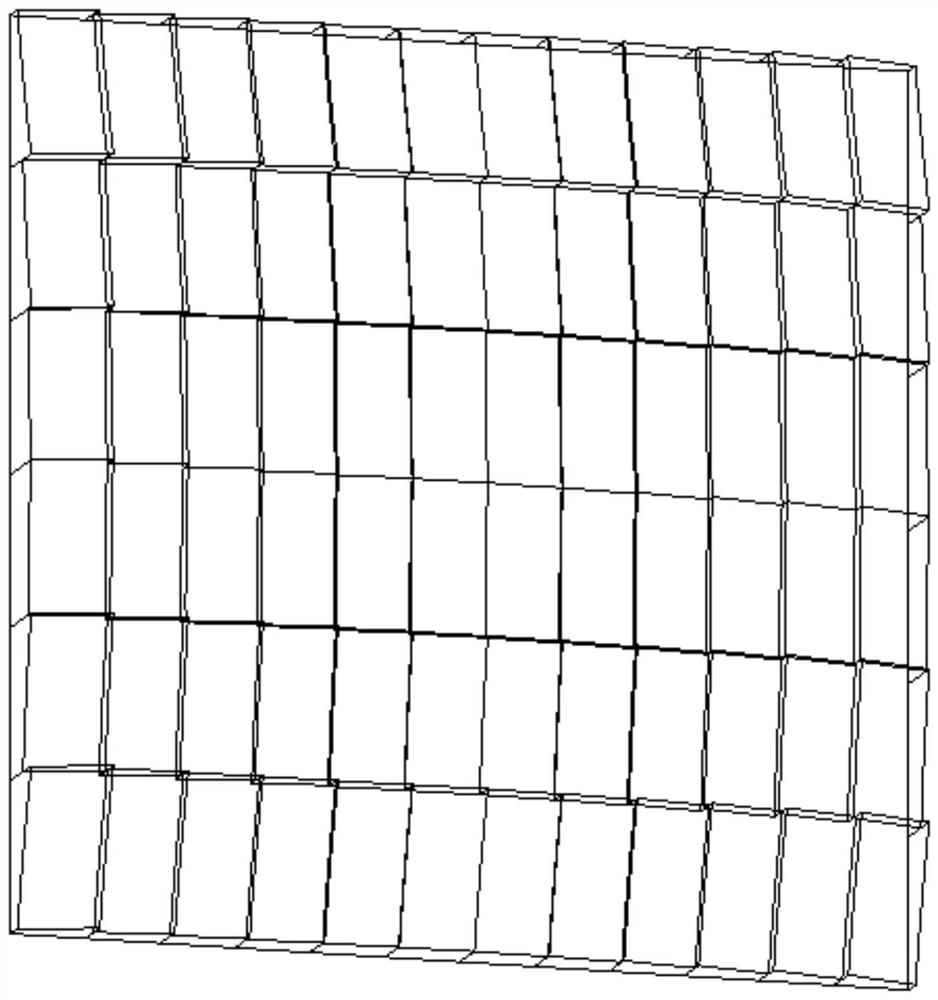

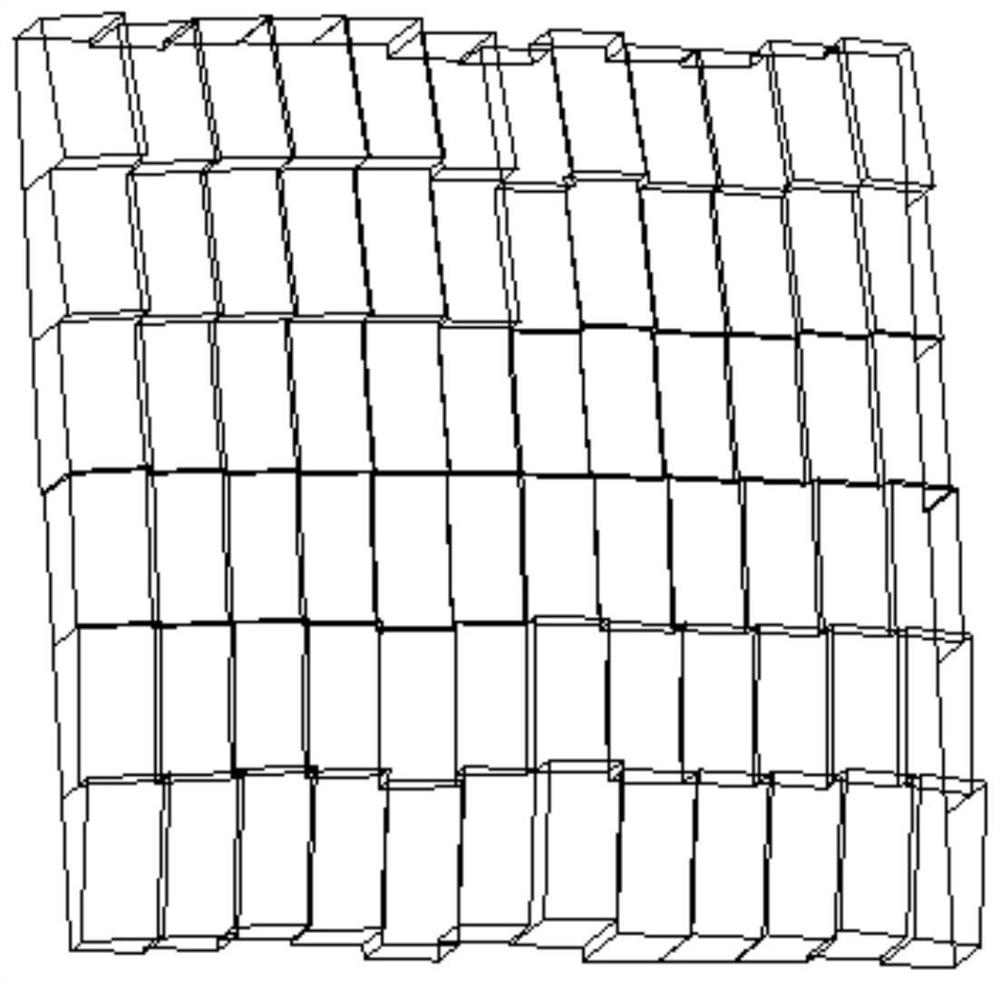

[0029] According to the non-imaging optical design theory, the free-form surface of the rear surface of the sub-lens is designed. Using the principle of energy mapping, calculate the relative position of each sub-lens and the shape of the free-form surface on the rear surface, process on a whole piece of lens material, and only process the rear surface of the material to form "sub-lenses" one by one, and complete the "sub-lens" of the sub-lens Stitching" to design a complete free-form surface microlens array.

[0030] Such as figure 1 As shown in Fig. 1, the free-form surface and the target surface are first divided into equal-energy grids, and then the one-to-one correspondence between the free-form surface and the target surface is established according to the method of energy mapping. The present invention is mainly applied to DMDs with an aspect ratio of 1:2, so the aspect ratio of each sub-lens is also designed to be 1:2. Taking the front surface of the sub-lens as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com