Oil gasifier and oil burner

An oil burner, oil and gas technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of insufficient metal powder connection strength, blockage of oil gun nozzles, difficult quality, etc., to achieve compact structure, output will not be reduced, The effect of large heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

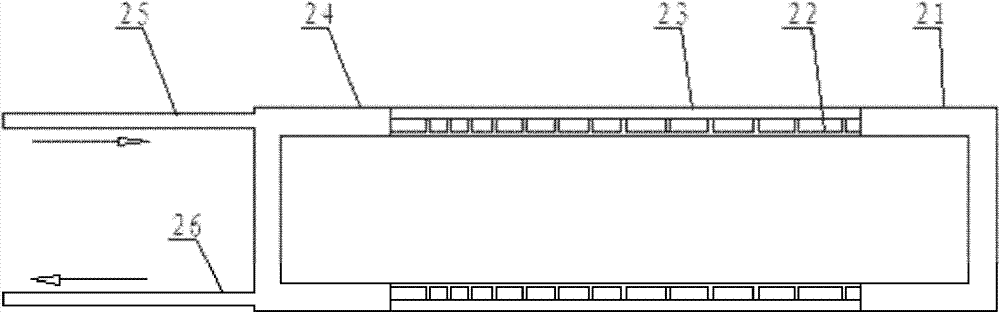

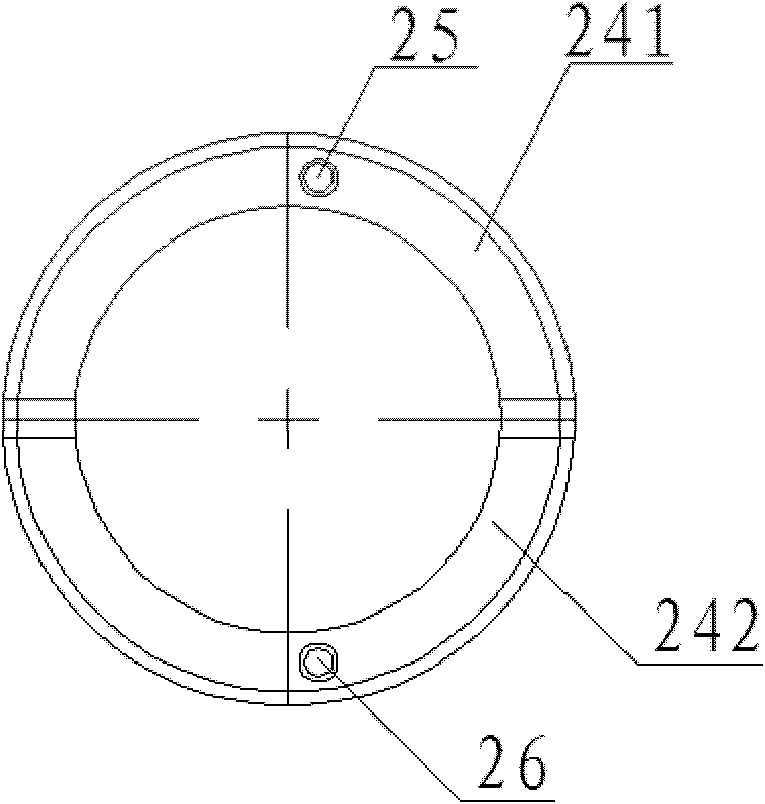

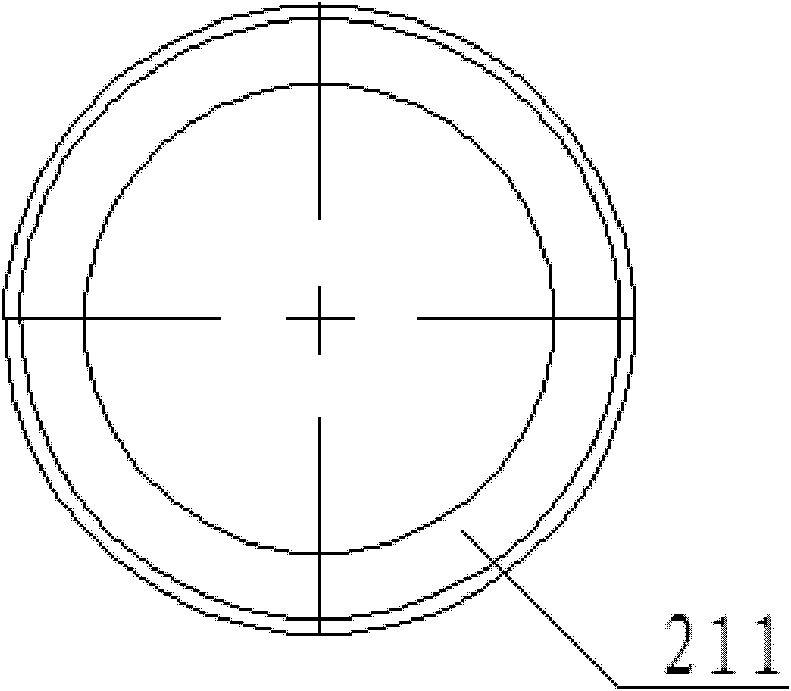

[0022] figure 1 The structure of an oil-gasifier according to an embodiment of the present invention is shown. Such as figure 1 As shown, the oil vaporizer includes a right end cover 21, a preferably hollow cylindrical inner sleeve 22, a preferably hollow cylindrical outer sleeve 23, a left end cover 24, an oil inlet joint 25, and an oil and gas output joint 26, wherein the outer sleeve 23 surrounds the inner sleeve 22. The right end cap 21 is airtightly arranged at one end of the inner sleeve 22 and the outer sleeve 23, and the left end cap 24 is airtightly arranged at the other end of the inner sleeve 22 and the outer sleeve 23, and between the right end cap 21 and the left end cap 24 and An annular space is formed between the inner sleeve 22 and the outer sleeve 23, and the annular space is provided with one or more continuous spiral grooves such as a rectangular cross section, and these spiral grooves will be formed by the left end cover 24 and the ends of the inner sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com