Solar heat collector and water heater

A technology for solar thermal collectors and water heaters, which is applied to solar thermal collectors, solar thermal energy, solar thermal collectors using working fluid, etc. Cost, easy installation, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

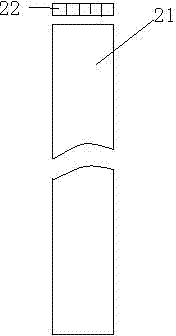

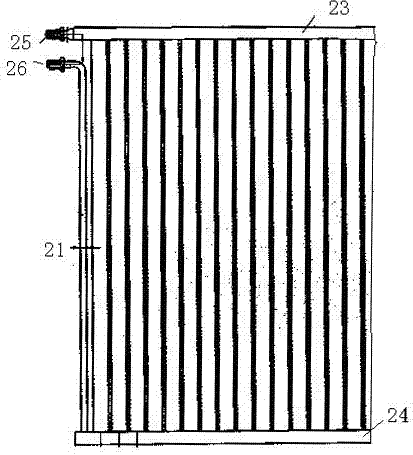

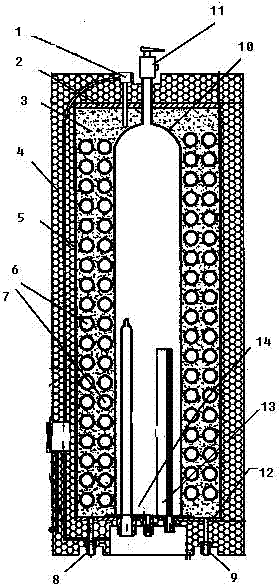

[0030] Figure 1-2The middle solar heat collector is provided with a horizontal upper collector 23 and a horizontal lower collector 24 (one end of which is blocked) at the bottom, including a liquid inlet pipe 26 and a liquid outlet pipe 25 connected to the upper collector. One end of the flow tube and the lower header at the bottom, a metal heat collector plate 21 with densely arranged internal flow channels is arranged between the upper header and the lower header, and the internal flow channels of the metal heat collector plate are connected to the upper header And the lower header, the internal flow channel of the metal heat collecting plate is especially arranged by uniform thin tubes 22, and the cross-sectional area of the thin tubes is 3.5-6 square millimeters. It is better to use aluminum or aluminum alloy for the upper collector and the lower collector, and the metal heat collector plate is preferably made of aluminum or aluminum alloy. Considering the preparation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com