Furnace door seal device

A furnace door sealing and furnace door technology, used in furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as poor sealing performance, and achieve the effect of ensuring sealing performance, ensuring sealing, and convenient loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

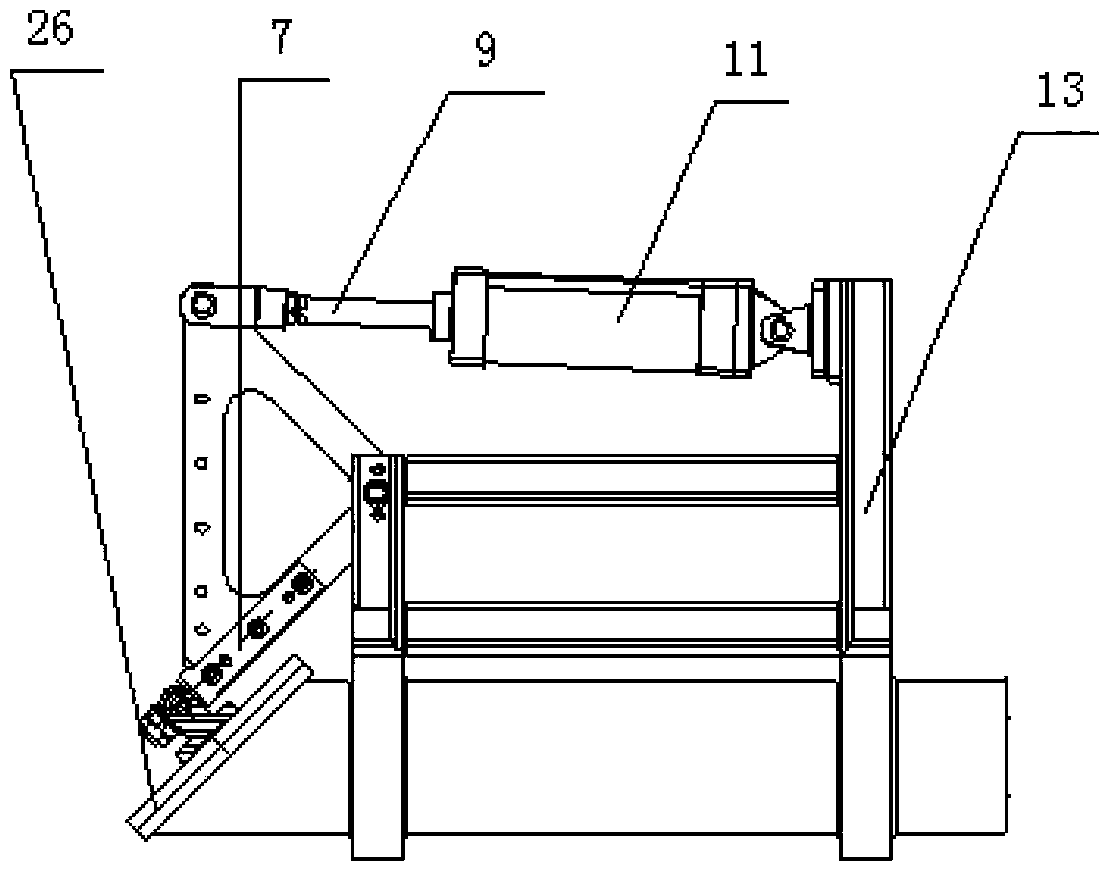

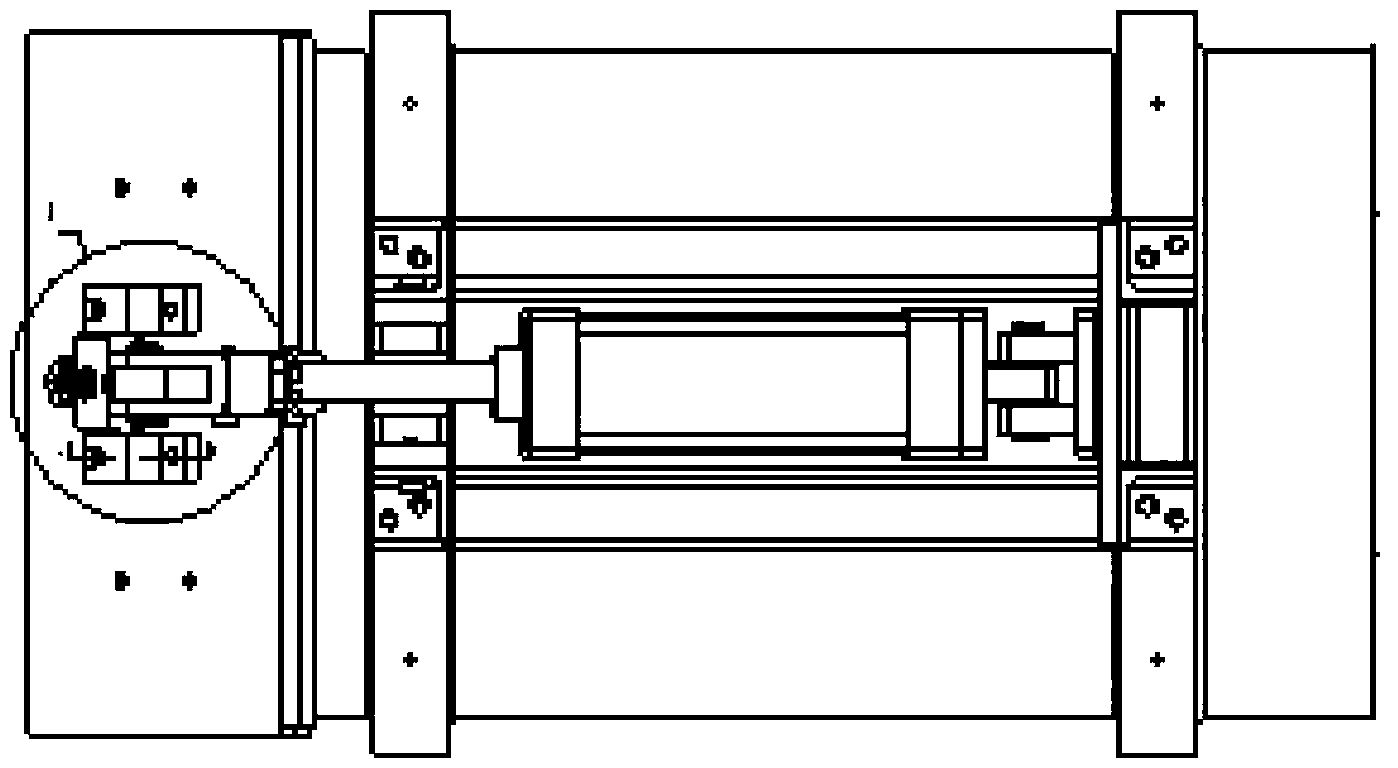

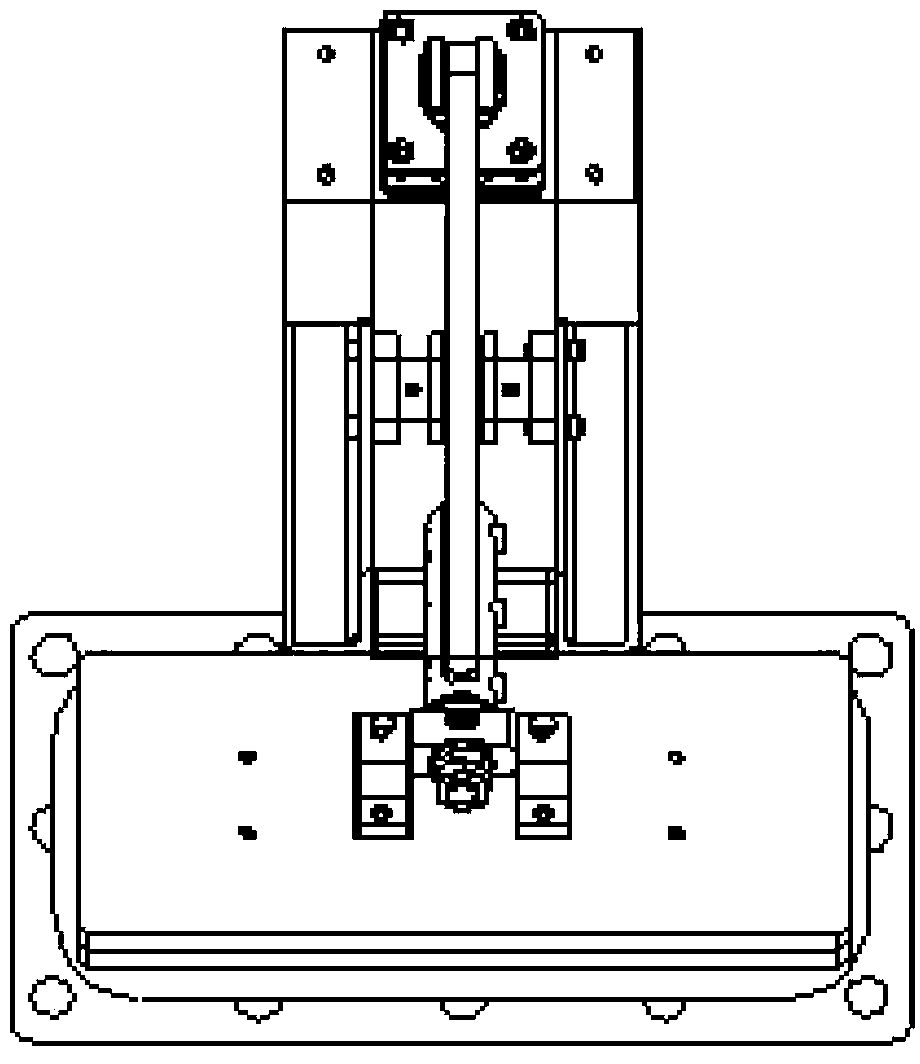

[0041] In an embodiment, a furnace door sealing device includes a furnace door cylinder 11, a furnace door opening and closing lever 7 and a furnace door cover plate 18 with a sealing plate 27. The furnace door cylinder 11 is connected with the mounting bracket 13 through the ear-shaped connecting seat pin 12, the furnace door opening and closing lever 7 is connected with the cylinder piston rod 9 through the Y-joint pin 8 installed on the cylinder piston rod 9, and the furnace door cover plate 18 and the furnace door opening and closing lever 7 are connected by a mounting shaft 29. The center of the mounting shaft 29 is machined with a shaft hole with a diameter of ΦD2. The shaft hole is matched with the rotating shaft 19 at the end of the opening and closing lever 7. Both ends of the mounting shaft have a section of rotating shaft I16 with a diameter of ΦD1 and coaxial. Cooperating with the bearing seat 25 fixedly connected to the furnace door cover, the axes of ΦD2 and ΦD1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com