Gainp/gaas/inganas/ge four-junction solar cell and preparation method thereof

A technology of solar cells and sub-cells, applied in the field of solar cells, can solve problems affecting cell conversion efficiency, complex buffer layer growth technology, shortage of Ge materials, etc., and achieve the effects of improving cell efficiency, reducing cost and resource consumption, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

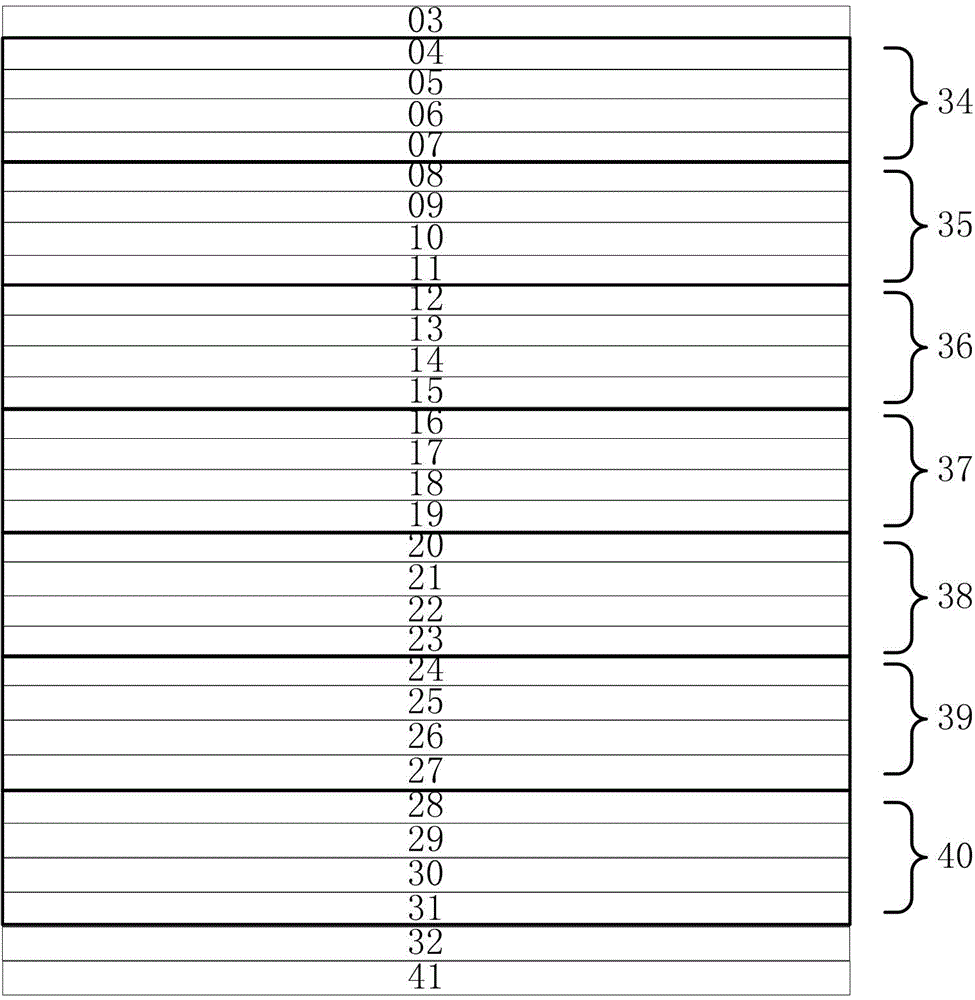

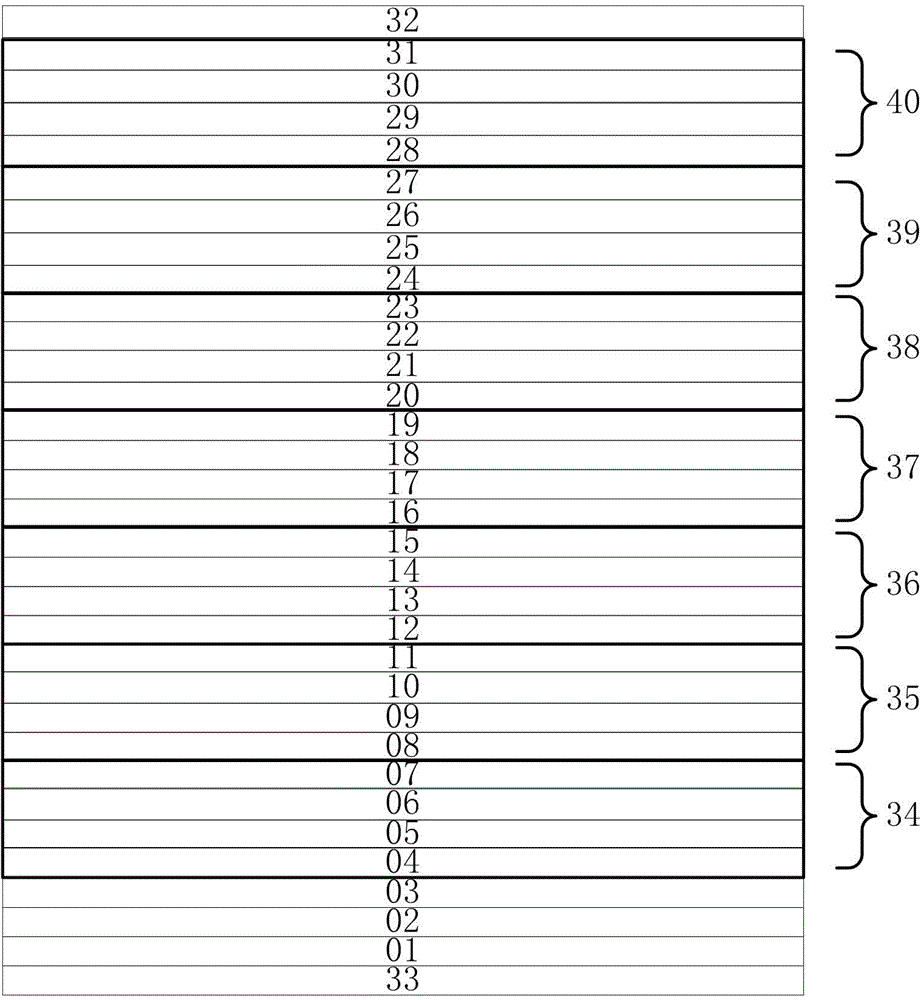

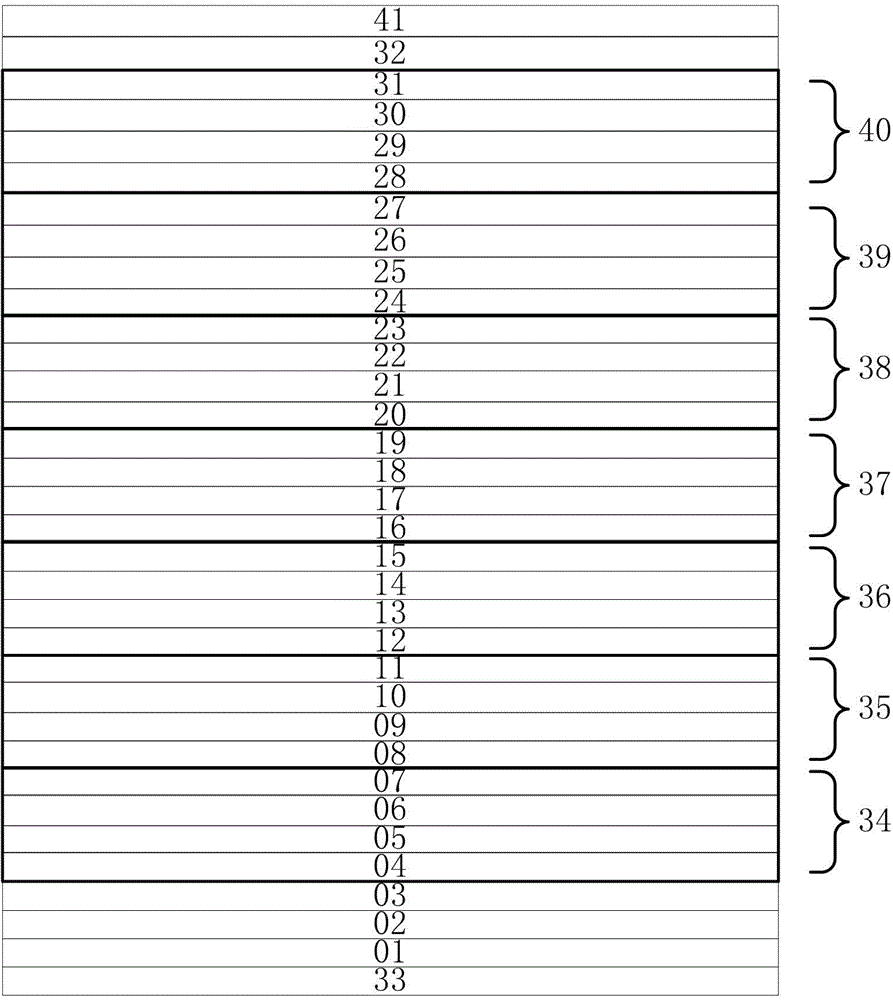

[0026] figure 1 Shown is a structural diagram of a GaInP / GaAs / InGaNAs / Ge four-junction solar cell provided in this specific embodiment.

[0027] This specific embodiment provides a GaInP / GaAs / InGaNAs / Ge four-junction solar cell, the bandgap combination is 1.90eV / 1.42eV / 1.00eV / 0.67eV, and the GaInP / GaAs / InGaNAs / Ge four-junction solar cell includes Si supporting substrate 41, and first contact layer 32 of Ge or GaInAs, Ge subcell 40, first tunnel junction 39, InGaNAs subcell 38, second tunneling junction arranged in sequence on the surface of said Si supporting substrate 41 Junction 37, GaAs subcell 36, third tunnel junction 35, GaInP subcell 34 and second contact layer 03 of InGaAs or GaAs.

[0028] As an optional implementation mode, the thickness of the second contact layer 03 of InGaAs or GaAs is in the range of 300nm to 700nm, and the doping concentration is greater than 2.0E18cm -3 .

[0029] 2.0E18cm appears in the application documents -3 Indicates 2.0×10 18 cm -3 ...

no. 2 Embodiment approach

[0046] This specific embodiment provides a method for preparing a GaInP / GaAs / InGaNAs / Ge four-junction solar cell. The bandgap combination of the solar cell is 1.90eV / 1.42eV / 1.00eV / 0.67eV, and each layer of the GaInP / GaAs / InGaNAs / Ge four-junction cell in the above manufacturing method is grown by MOCVD or MBE. If the MOCVD method is used, the N-type dopant atoms are Si, Se, S or Te, and the P-type dopant atoms are Zn, Mg or C; if the MBE method is used, the N-type dopant atoms are Si, Se, S, Sn or Te, P-type dopant atoms are Be, Mg or C.

[0047] Figure 4 It is a flow chart of the steps of the GaInP / GaAs / InGaNAs / Ge four-junction solar cell provided in this specific embodiment.

[0048] Described preparation method comprises:

[0049] Step S401, providing a GaAs substrate;

[0050] Step S402, growing the second contact layer, the GaInP sub-cell, the third tunnel junction, the GaAs sub-cell, the second tunnel junction, the InGaNAs sub-cell, the first tunnel junction, the Ge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com