GaInP/GaAs/Ge/Ge four-junction solar cell and preparation method thereof

A technology of solar cells and sub-cells, which is applied in the field of solar cells and can solve problems such as insufficient energy conversion and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

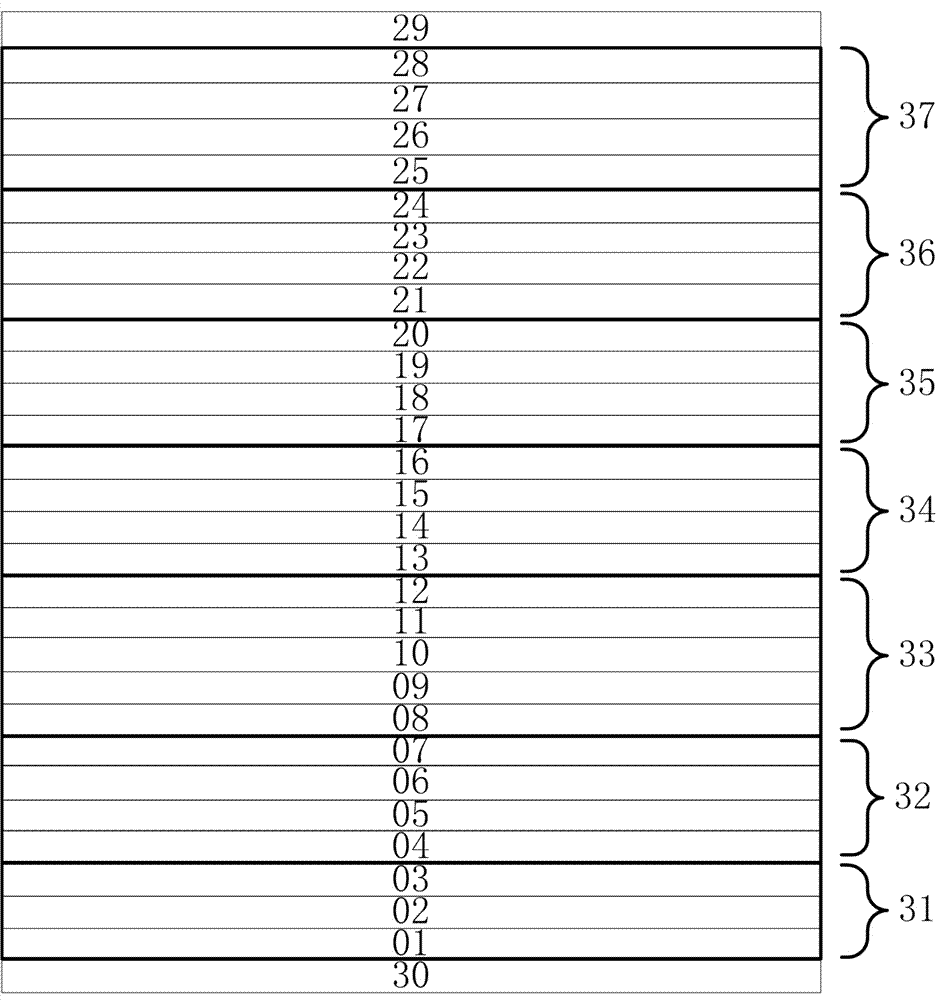

[0021] figure 1 Shown is a structural schematic diagram of a first embodiment of a GaInP / GaAs / Ge / Ge four-junction solar cell with a buffer layer.

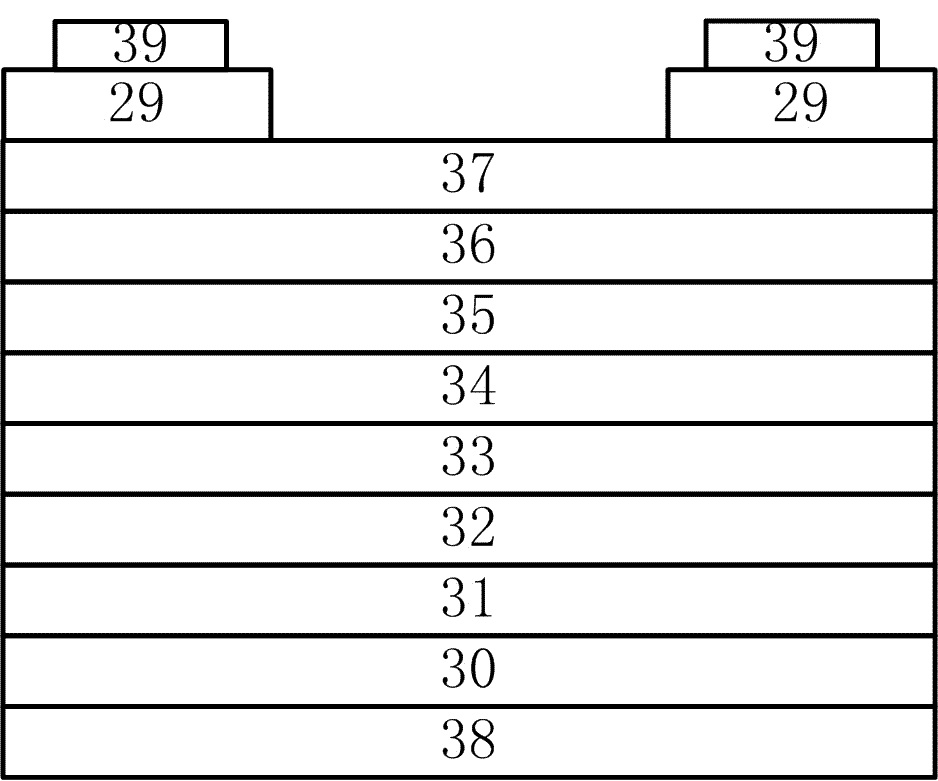

[0022] figure 2 Shown is a schematic diagram of the product structure of a first embodiment of a GaInP / GaAs / Ge / Ge four-junction solar cell.

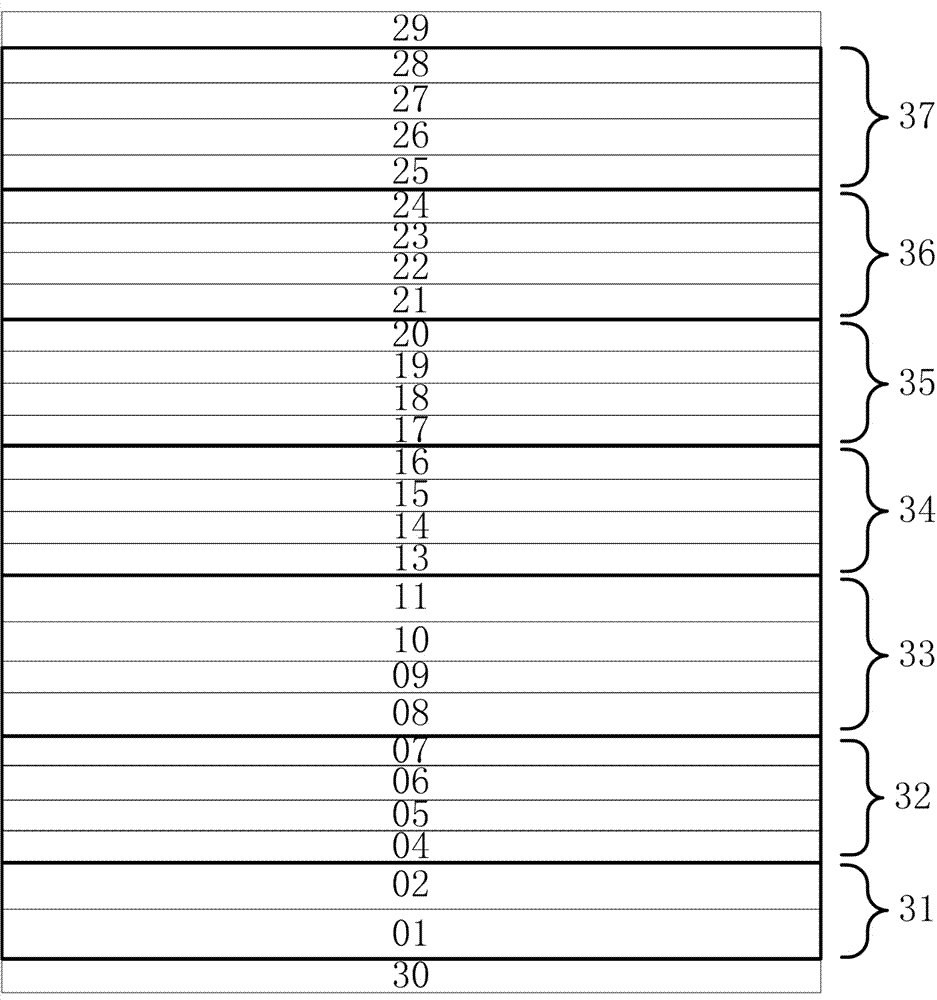

[0023] image 3 Shown is a schematic structural diagram of a first embodiment of a GaInP / GaAs / Ge / Ge four-junction solar cell without a buffer layer.

[0024] This embodiment provides a GaInP / GaAs / Ge / Ge four-junction solar cell grown in a front-mount manner, and the bandgap combination is 1.90eV / 1.42eV / 0.67eV / 0.67eV. The structure of the GaInP / GaAs / Ge / Ge four-junction cell solar cell is as follows image 3 As shown, it includes a Ge substrate layer 30, and a first Ge subcell 31, a first tunnel junction 32, a second Ge subcell 33, a second tunnel junction 34, and a GaAs subcell arranged in sequence on the Ge substrate layer 30. A subcell 35 , a third tunnel junction 36 , a GaInP subcell 3...

no. 2 Embodiment approach

[0051] This embodiment provides a method for preparing a GaInP / GaAs / Ge / Ge four-junction solar cell using a front mounting method, such as Figure 4 shown, including:

[0052] Step 401, providing a substrate layer;

[0053] Step 402, growing a first Ge sub-cell on the surface of the Ge substrate layer;

[0054] Step 403, growing a first tunnel junction on the surface of the first Ge sub-cell;

[0055] Step 404, growing a second Ge sub-cell on the surface of the first tunnel junction;

[0056] Step 405, growing a second tunnel junction on the surface of the second Ge sub-cell;

[0057] Step 406, growing GaAs sub-cells on the surface of the second tunnel junction;

[0058] Step 407, growing a third tunnel junction on the surface of the GaAs sub-cell;

[0059] Step 408, growing GaInP sub-cells on the surface of the third tunnel junction;

[0060] Step 409, growing a contact layer on the surface of the GaInP sub-cell.

[0061] The above steps are grown by MOCVD (Metal Organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com