Waveguide ring flange, flexible waveguide assembly containing waveguide ring flange and assembly method of flexible waveguide assembly

A flange and flexible waveguide technology, applied in waveguide-type devices, waveguides, electrical components, etc., can solve the problem of high-power microwave energy transmission and heat dissipation, and achieve simple and convenient assembly and disassembly, easy operation, and continuous guarantee. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

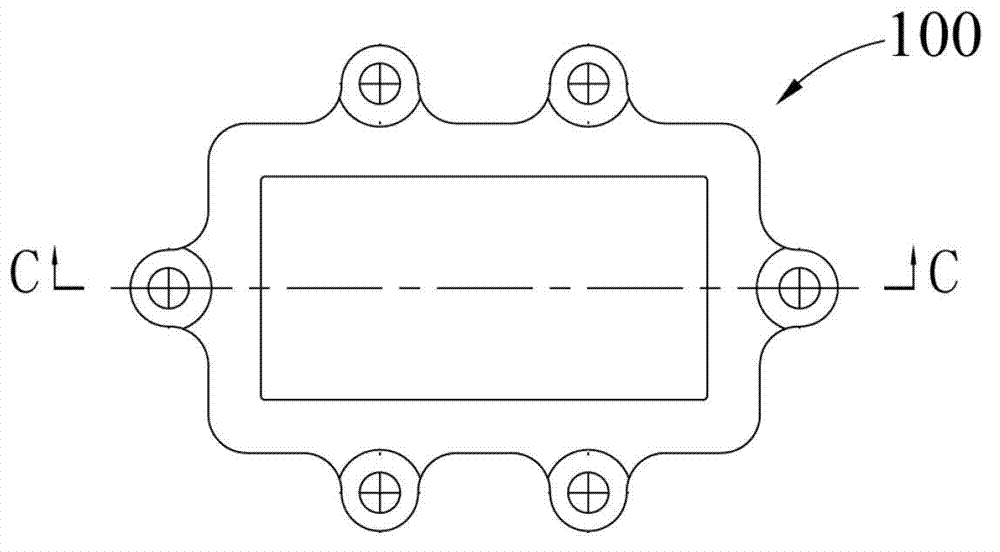

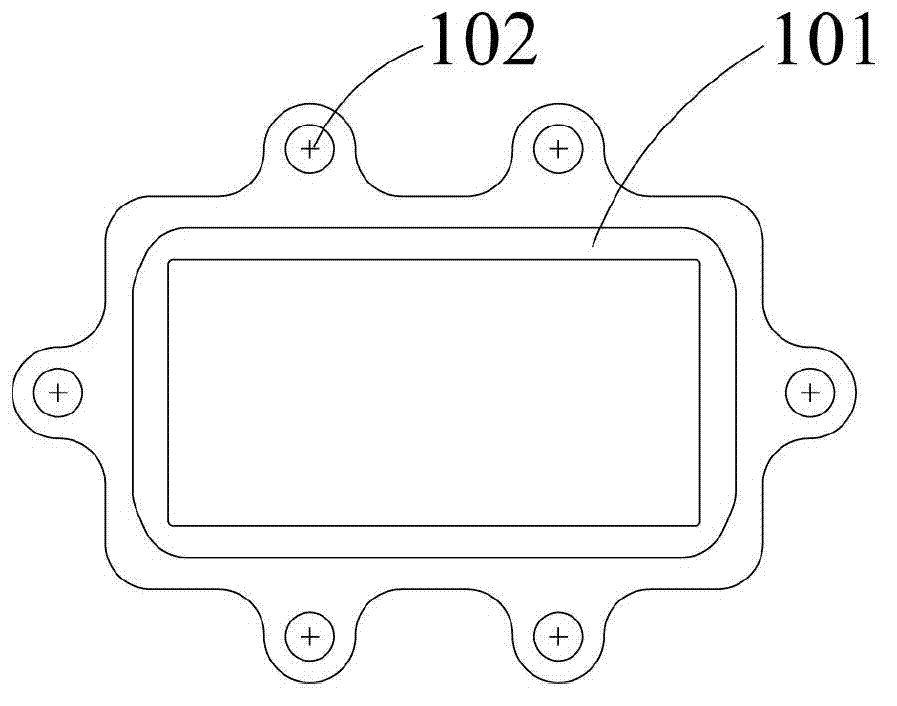

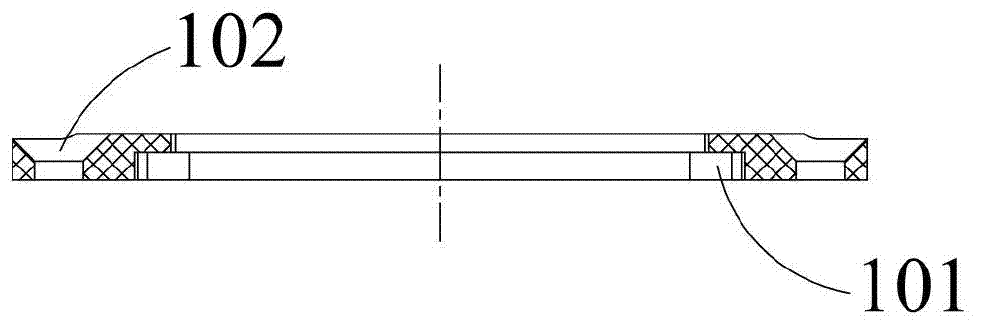

[0046] Example 1: Combining Figure 1 to Figure 6 The waveguide flange of the present invention is described, which consists of a first flange 100 and a second flange 200 . Such as figure 1 and image 3 As shown, the first flange 100 is a rectangular waveguide flange, the inner wall of which is closed and stepped and has a connecting surface 101 for connecting the waveguide, and the outer edge of the first flange 100 is evenly distributed with six installation Hole 102.

[0047] Such as Figure 4 to Figure 7 As shown, the second flange 200 is composed of a waveguide fixing part 201 and an outer sheath fixing part 202 which are integrated and communicated with each other. The outer diameter of the waveguide fixing part 201 is smaller than the inner diameter of the outer sheath fixing part 202 . The upper end surface of the waveguide fixing part 201 has a groove 205 matched with the first flange 100, and two water injection ports 203 are symmetrically arranged on the side wa...

Embodiment 2

[0049] Embodiment 2: The flexible waveguide assembly of the present invention is a transmission device used to supply energy to a tokamak. During high-power microwave transmission, a large amount of heat will be generated in the transmission medium due to transmission loss, so a cooling device is required to cool it To ensure the security of the transmission system. combine Figure 8 The flexible waveguide assembly 1 of the present invention is illustrated, which includes a waveguide 30, an outer sheath 40, a waveguide flange one 10 and a waveguide flange two 20, and the two ends of the waveguide 30 respectively pass through the waveguide flange one 10 and the waveguide flange two. The inner cavity of the waveguide flange 2 20 is welded on the two first flanges (11, 21), and the first flanges (11, 21) are respectively installed on the corresponding second flanges (13, 23 ) in the groove of the connecting hole and threaded on the second flange (13, 23). The outer sheath 40 is...

Embodiment 3

[0053] Example Three: Combining Figure 9 The flexible waveguide assembly 2 of the present invention is different from the second embodiment in that the waveguide flange 3 50 in this embodiment has a water injection port 3 52, the waveguide flange 4 60 has a water injection port 4 62, and the waveguide flange 4 60 has a water injection port 4 62. Both ends of the pipe 30 are respectively welded on the first flange (51, 61). The cooling water channel in this embodiment has only one water injection port and a water outlet, and its cooling efficiency is not as good as that of the double water injection ports in Embodiment 2, so it can be used in flexible waveguide components with lower power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com