Camera module

一种照相机、小型的技术,应用在照相机、照相机的机身、仪器等方向,能够解决很难定位透镜和固体摄像器件、硅片切割不均匀等问题,达到摄像质量高、定位精度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

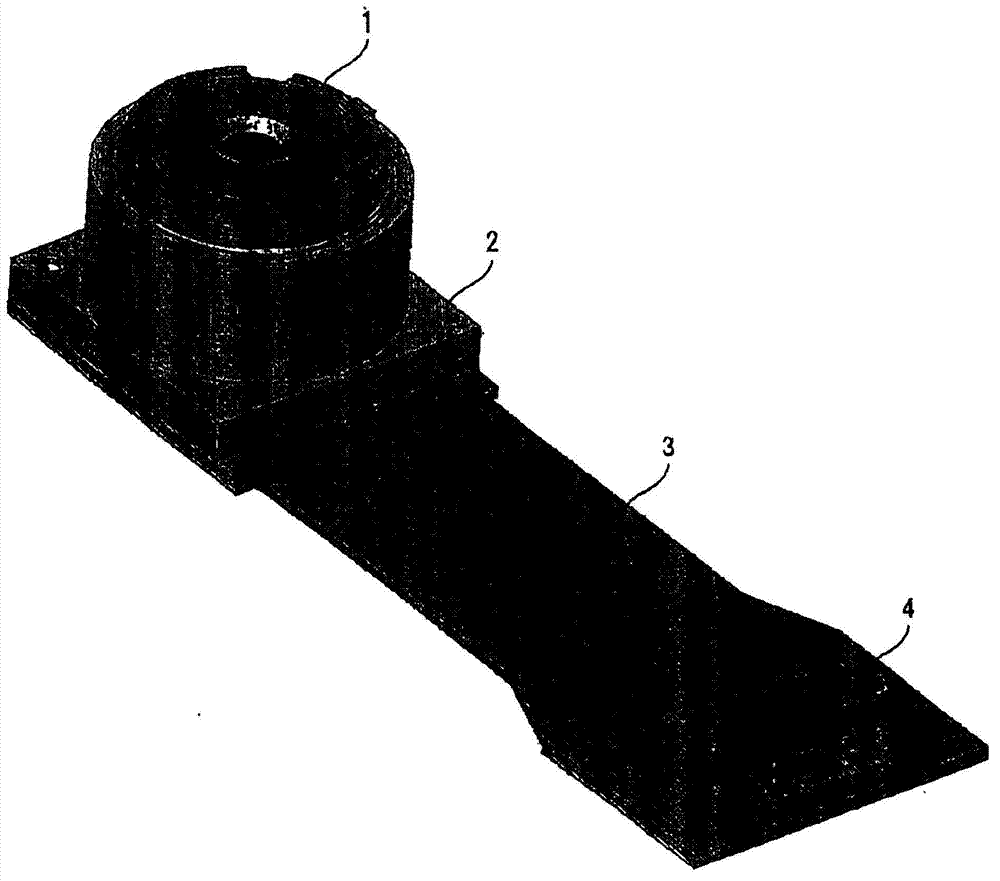

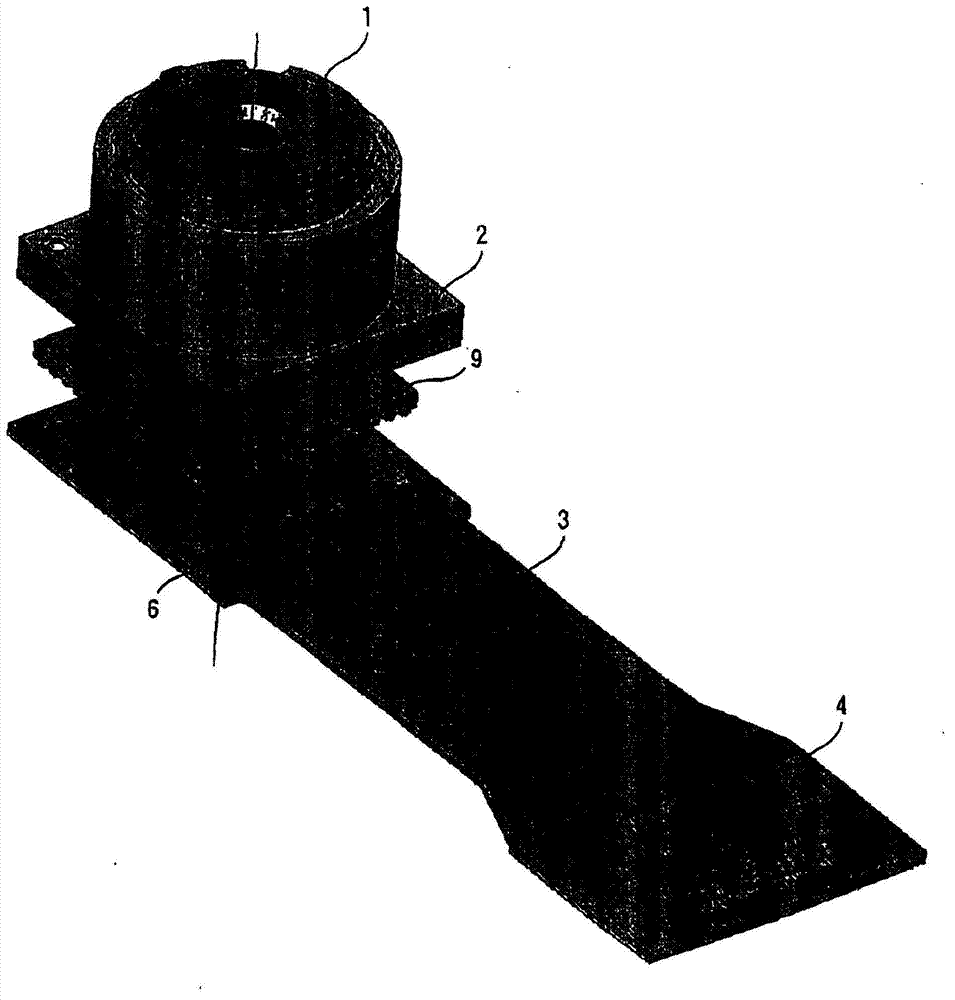

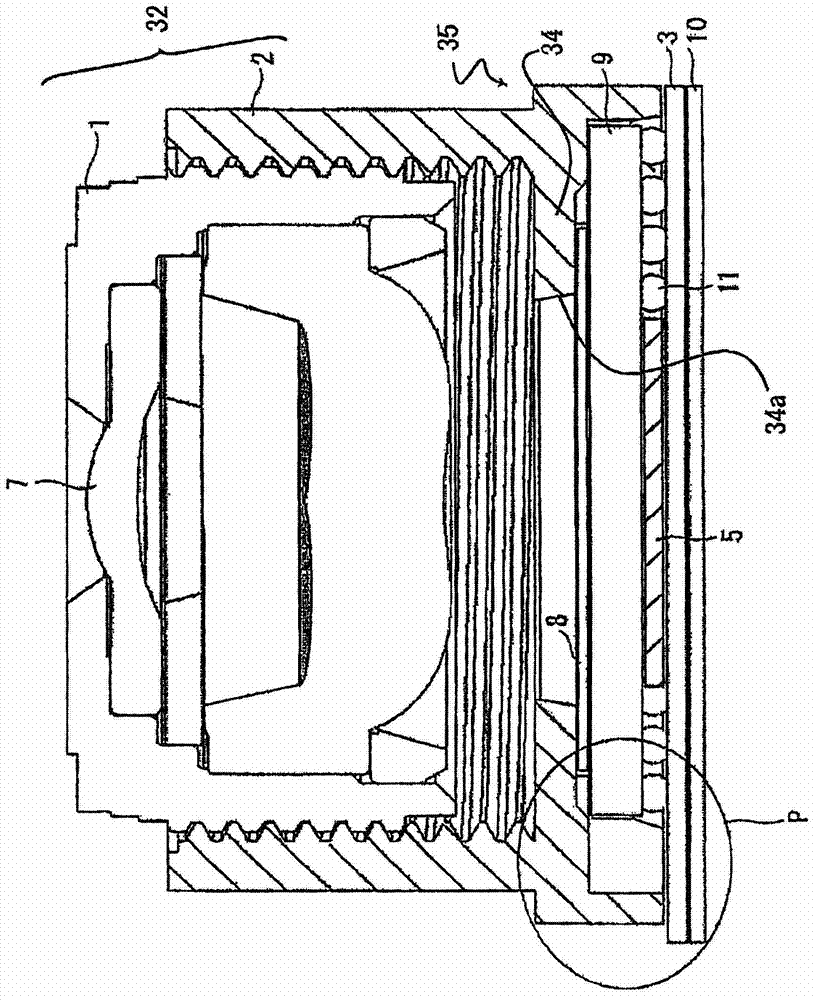

[0039] figure 1 It is a perspective view of the camera module of this invention. figure 2 It is an exploded perspective view of the camera module. in addition, image 3 is a cross-sectional view of the camera module.

[0040] Such as Figure 1~3 As shown, the camera module of the present invention has: lens module 1; Base 2; FPC circuit board 3; Connector 4; Solid-state imaging device 5; Capacitor 6; Lens 7; 10; and solder balls 11.

[0041] The lens module 1 has a cylindrical shape, and one or more lenses 7 are fixed to its inner peripheral surface with high precision. In addition to the lens 7 , an aperture or an O-ring may sometimes be provided on the lens module 1 . A cutting thread structure is provided on the outer peripheral surface of the lens module 1 so as to be screwed on the base 2 . The lens module 1 is made of, for example, a light-shielding synthetic resin such as black polycarbonate or polybutylene terephthalate.

[0042]The base 2 has a cylindrical sh...

Embodiment 1

[0093] The thickness of the lens holder 32 of the camera module of Example 1 was manufactured according to the following conditions. Furthermore, the composition of the camera module, and Figure 9The configuration shown is the same.

[0094] S∕(H×H)=0.1

Embodiment 2

[0096] The thickness of the lens holder 32 of the camera module of Example 2 was manufactured according to the following conditions. Furthermore, the composition of the camera module, and Figure 9 The configuration shown is the same.

[0097] S∕(H×H)=0.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com