Stewing machine and stewing method

A stewing and container technology, applied in the field of stewing machines and stewing, can solve the problems of excessive dissolution, long stewing time, damage, etc., and achieve the effects of improving solubility, shortening stewing time, and improving dissolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

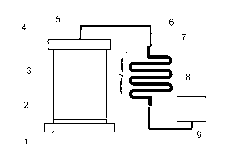

[0029] Such as figure 1 The shown stewing machine includes: an optional base 1, a heating element 2, a stewing container 3, a sealing cover 4 of the stewing container, a first conduit 5, a cooling fan 6, a condenser 7, a second conduit 8, and a buffer container 9. Wherein the first conduit 5, the cooling fan 6, the condenser 7, the second conduit 8, and the buffer container 9 are sealed and communicated in sequence to form a negative pressure generating device, which is sealed with the stewing container 3 through the stewing container sealing cover 4 connected.

[0030] Taking ingredients stew as an example, its working principle and stewing method are as follows:

[0031] Put the ingredients into the container 3, put it on the base 1, cover the stewing container sealing cover 4 tightly, and heat the heating element 2 with electricity to stew, and the steam generated during stewing enters the condenser through the conduit 5 , the steam is cooled into water under the action ...

Embodiment 2

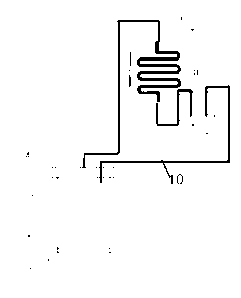

[0041] Such as figure 2As shown, in this embodiment, on the basis of Embodiment 1, a siphon tube 10 is added. One end of the siphon tube 10 is airtightly connected with the stew container 3 , and the other end extends from the upper opening of the buffer container 9 to the bottom of the buffer container 9 . And there is a one-way valve in the siphon 10, which only allows the fluid to flow in one direction from the buffer container 8 to the stewing container 3; there is also a one-way valve in the first conduit 5 or the second conduit 8, which only allows the fluid to flow from the buffer container 8 to the stewing container 3; The stewing container 3 flows in one direction to the buffer container 8 .

[0042] Although the siphon tube 10 is added, due to the effect of the one-way valve, the steam generated during stewing will enter the condenser through the conduit 5 as in the first embodiment, and will not directly reach the buffer container 9 through the siphon tube 10 . As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com