Receiving main mould structure of returning ejector pins in step-type product

A step-type, product technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve problems such as unstable thimble thrust, unqualified products, friction and wear, and achieve low cost , product quality and appearance improvement, and the effect of long mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

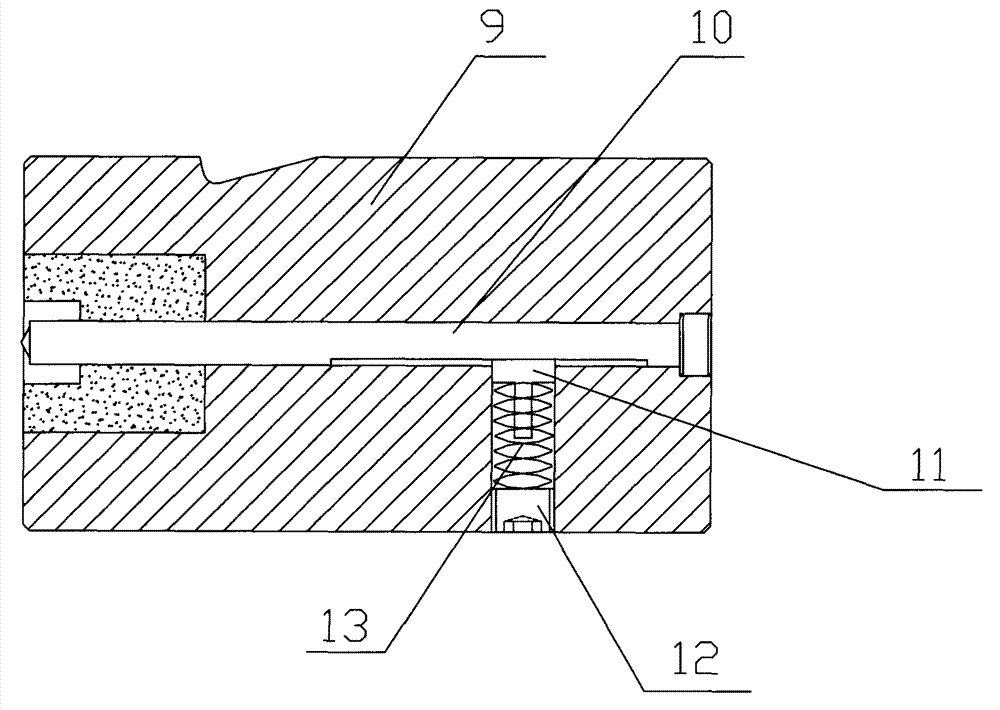

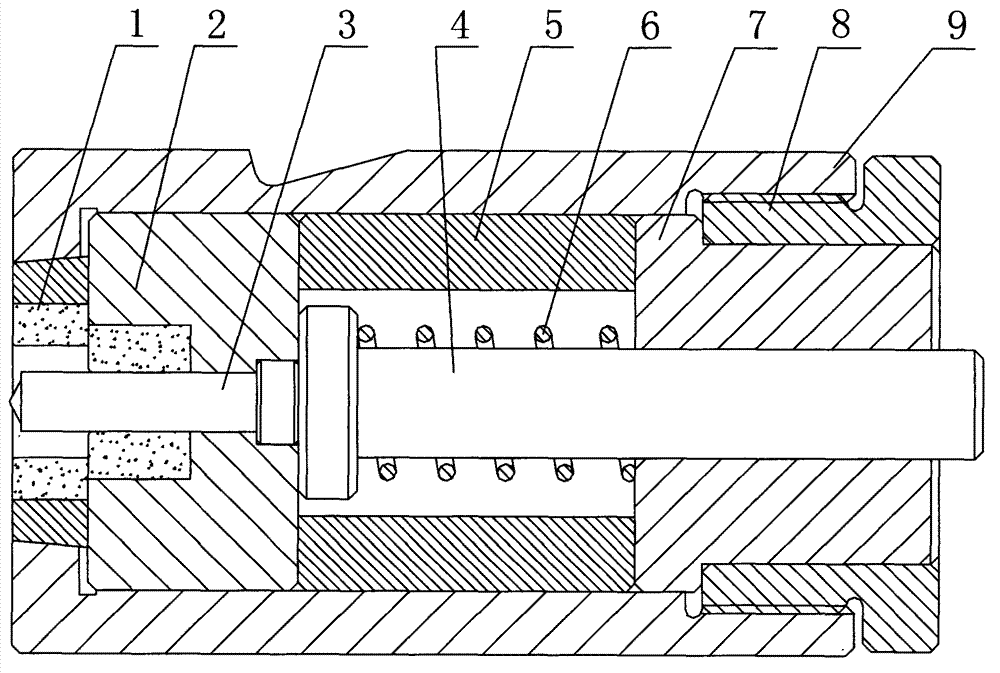

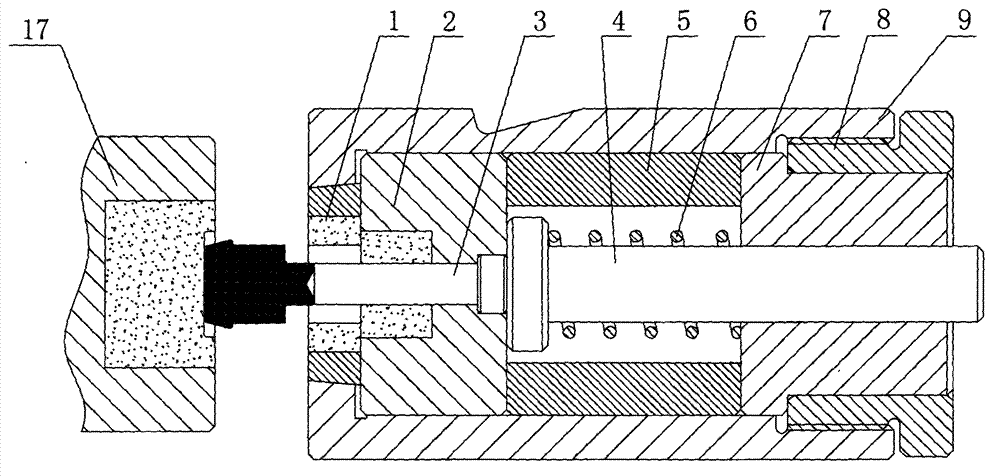

[0017] Such as figure 2 , Figure 6 and Figure 7 Shown is a step-type product ejector pin receiving material main mold structure, including a main mold cover 9, the bottom of the main mold cover 9 is provided with a back pad 7, and the inside of the back pad 7 is provided with a pushing ejector pin hole 14 , the pushing thimble hole 14 inside is provided with a pushing thimble 4, and the pushing thimble 4 includes a head and a rod, and a spring 6 is arranged on the rod between the head and the rear pad 7, and a spring 6 is arranged on the top of the rear pad 7, the pushing The outside of the thimble 4 and the inside of the main mold sleeve 9 are provided with an intermediate annular bushing 5, and the top of the intermediate annular bushing 5 is provided with an alloy mold 2, and the inside of the alloy mold 2 is provided with a material-receiving thimble hole 15, and a material-receiving thimble hole The inside of 15 is provided with material receiving thimble 3, is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com