Multi-station intelligent numerical-control grinding machine for knives and scissors

A multi-station, grinding machine technology, applied in the field of tool grinding machines, can solve the problems of low grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

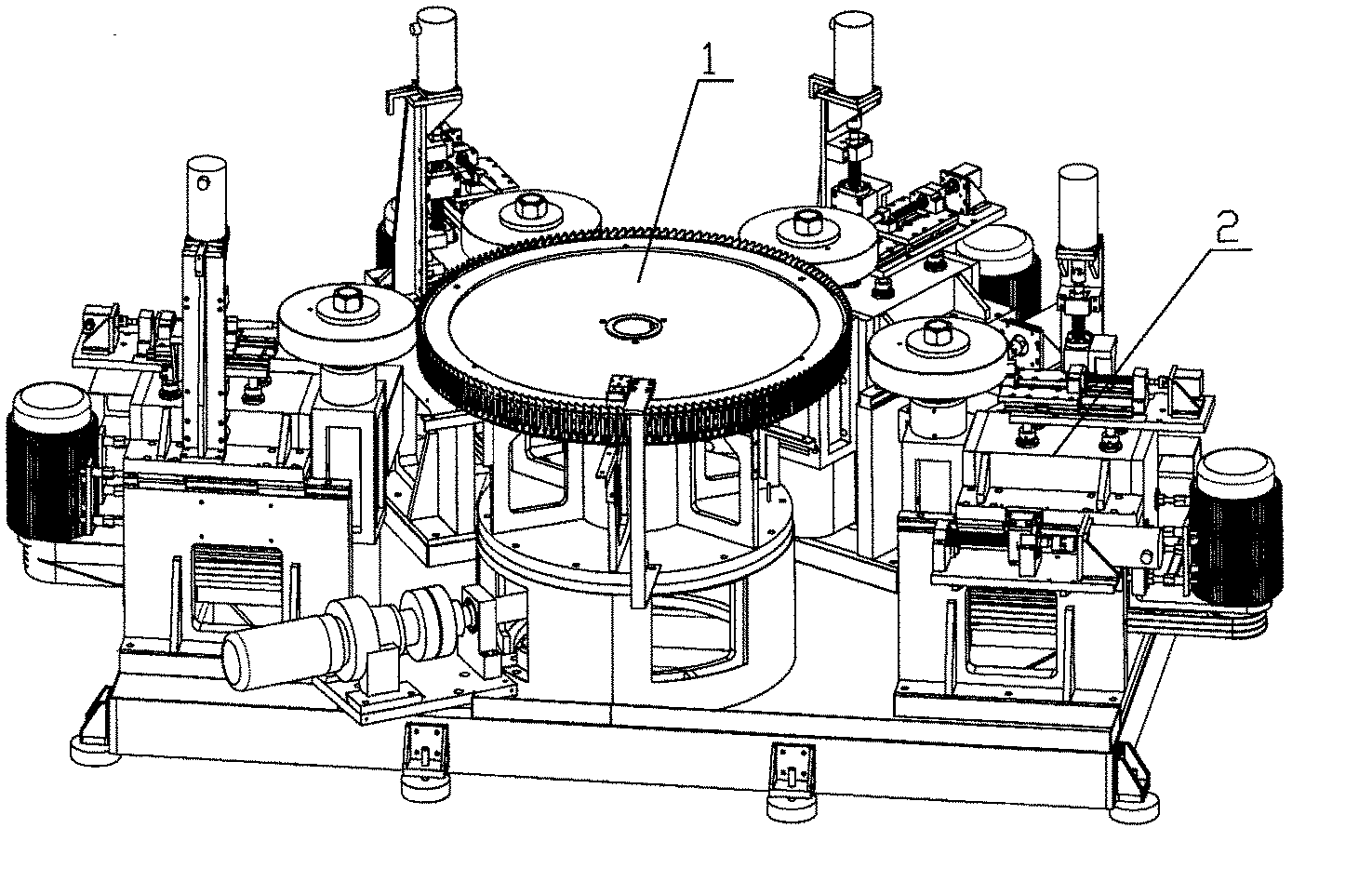

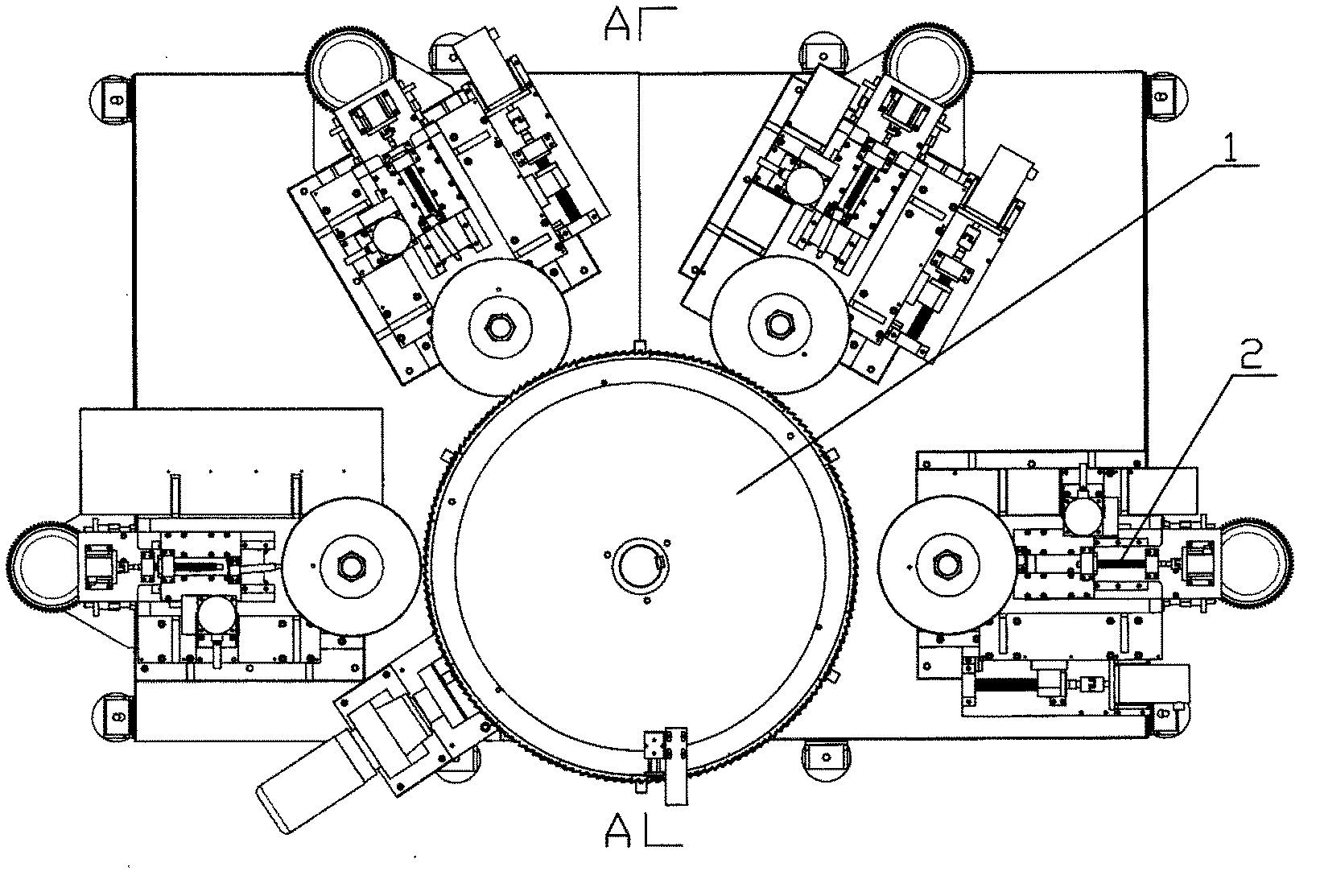

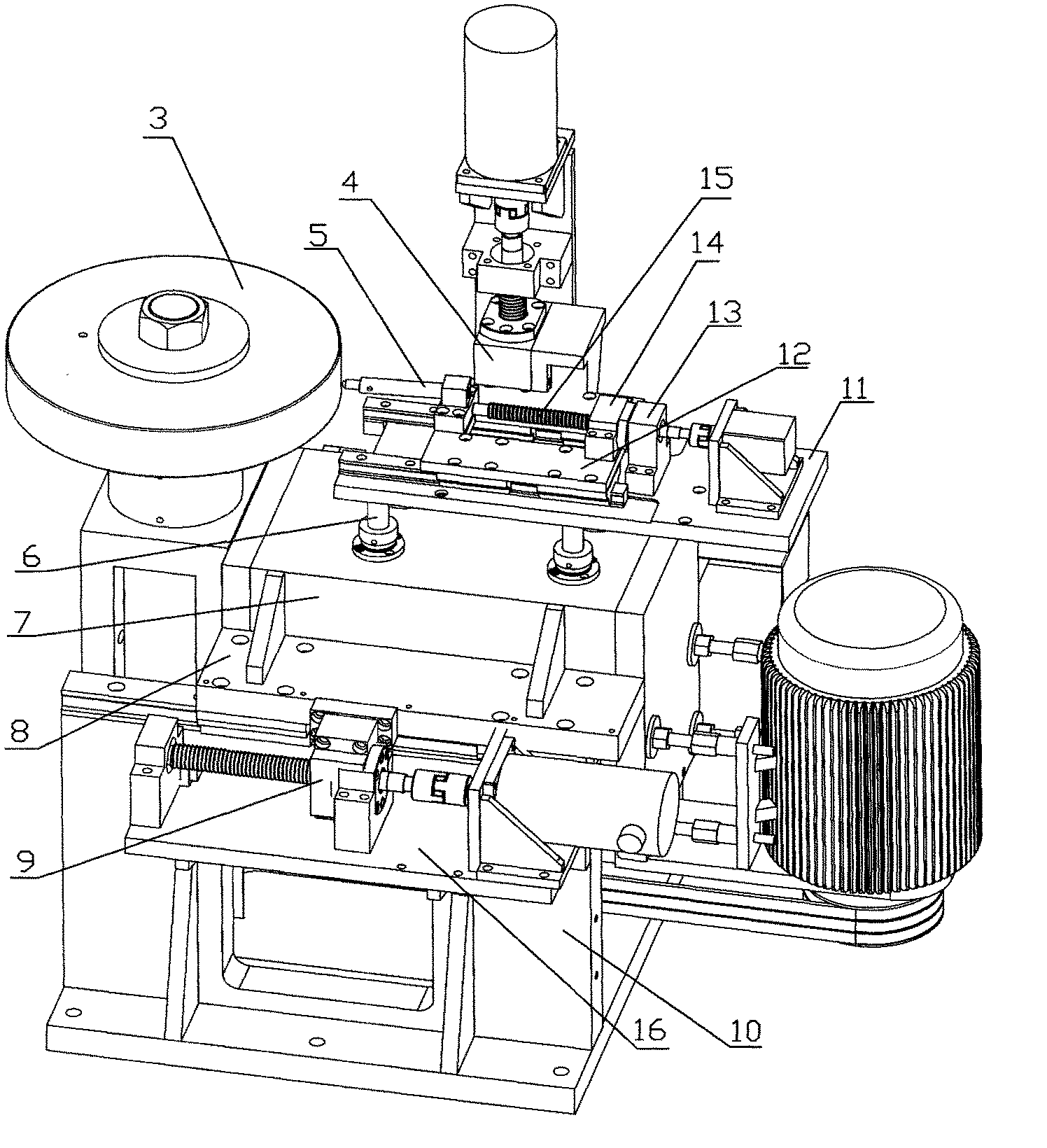

[0021] The structure of the present invention is: including the main motor, the grinding wheel 3, and the vertical vertical cover template, and it is characterized in that: the CNC grinding machine is composed of a workpiece turntable mechanism 1 and 2-6 unit grinding machines 2 distributed around the periphery of the workpiece turntable mechanism 1 ;

[0022] The workpiece turntable mechanism 1 consists of a disc base, a vertical bearing seat 19 fixed on the disc base, upper and lower bearings fitted on the vertical bearing seat 19, a vertical shaft fitted and fixed in the upper and lower bearing holes, and a bevel gear connected to the lower end of the vertical shaft The turntable connected to the input shaft of the commutator and the bevel gear commutator is composed of a stepping motor and a fixed workpiece turntable 18 fitted on the upper end of the vertical shaft; Fix several arc-shaped sheet-shaped fixtures 20, the inner arc-shaped surfaces of the arc-shaped sheet-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com