Anti-sedimentation center plate structure for railway vehicles

A railway vehicle and anti-siltation technology, which is applied in the direction of the lateral relative moving device between the underframe and the bogie, can solve the problems of the decline in the running quality of the vehicle and the impact on the vehicle, so as to reduce the manufacturing difficulty, overcome the wear and tear, reduce the cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

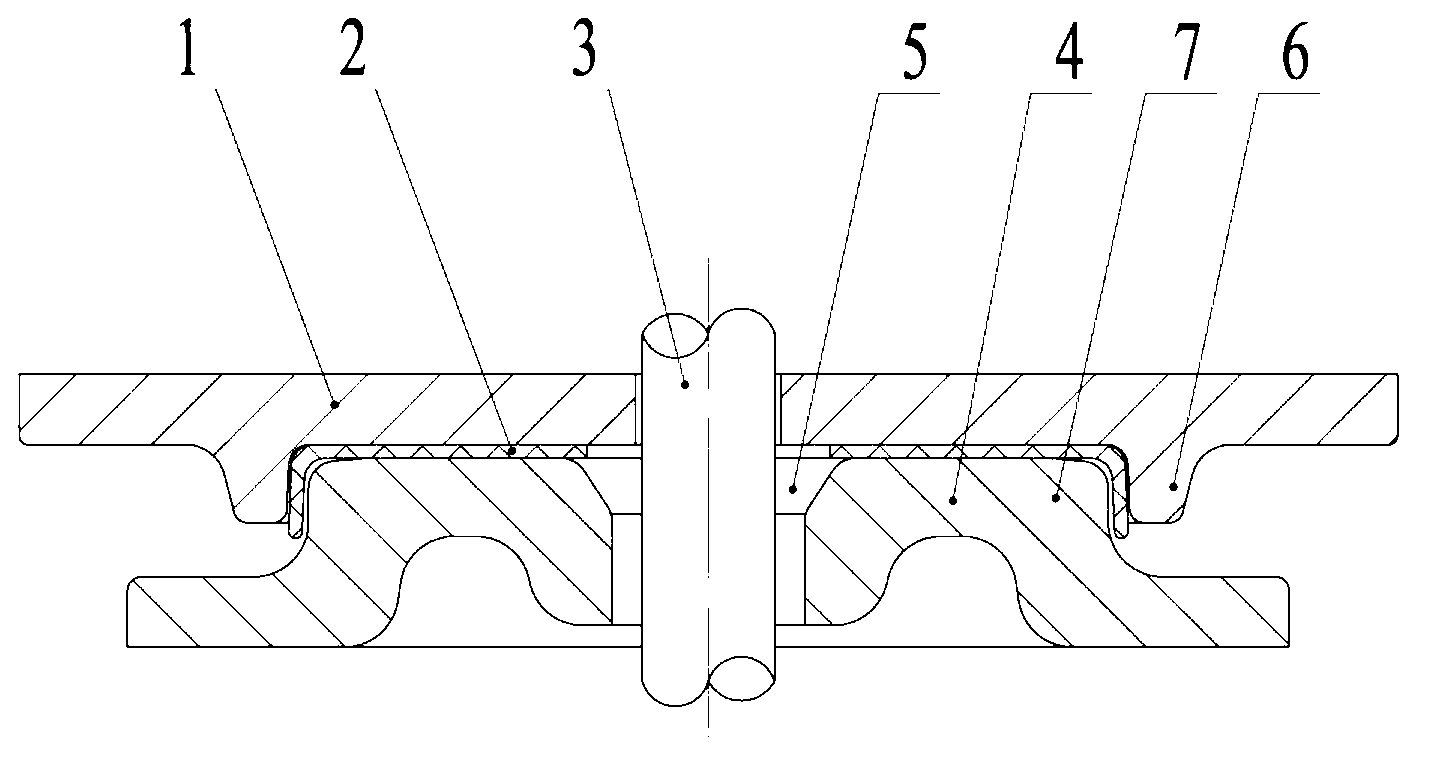

[0026] Embodiment 1, a railway vehicle anti-silting center plate structure, including an upper center plate 1 and a lower center plate 4, the edge of the upper center plate 1 is provided with a protrusion I6, and the middle is a groove, and the middle of the lower center plate 4 There is a protrusion II7, and the groove of the upper core plate 1 cooperates with the protrusion II7 of the lower core plate 4. This structure can effectively prevent sand and water from entering and depositing in the lower core plate, and there is no requirement for manufacturing accuracy. high. Between the groove of the upper center disc 1 and the protrusion II7 of the lower center disc 4, there is a center disc wearing disc 2 with a central hole. The middle of the upper center plate 1 and the lower center plate 4 are respectively provided with a center hole, and the center hole cooperates with the center pin 3 . The size of the center hole of the center disc wear disc 2 is larger than the size of...

Embodiment 2

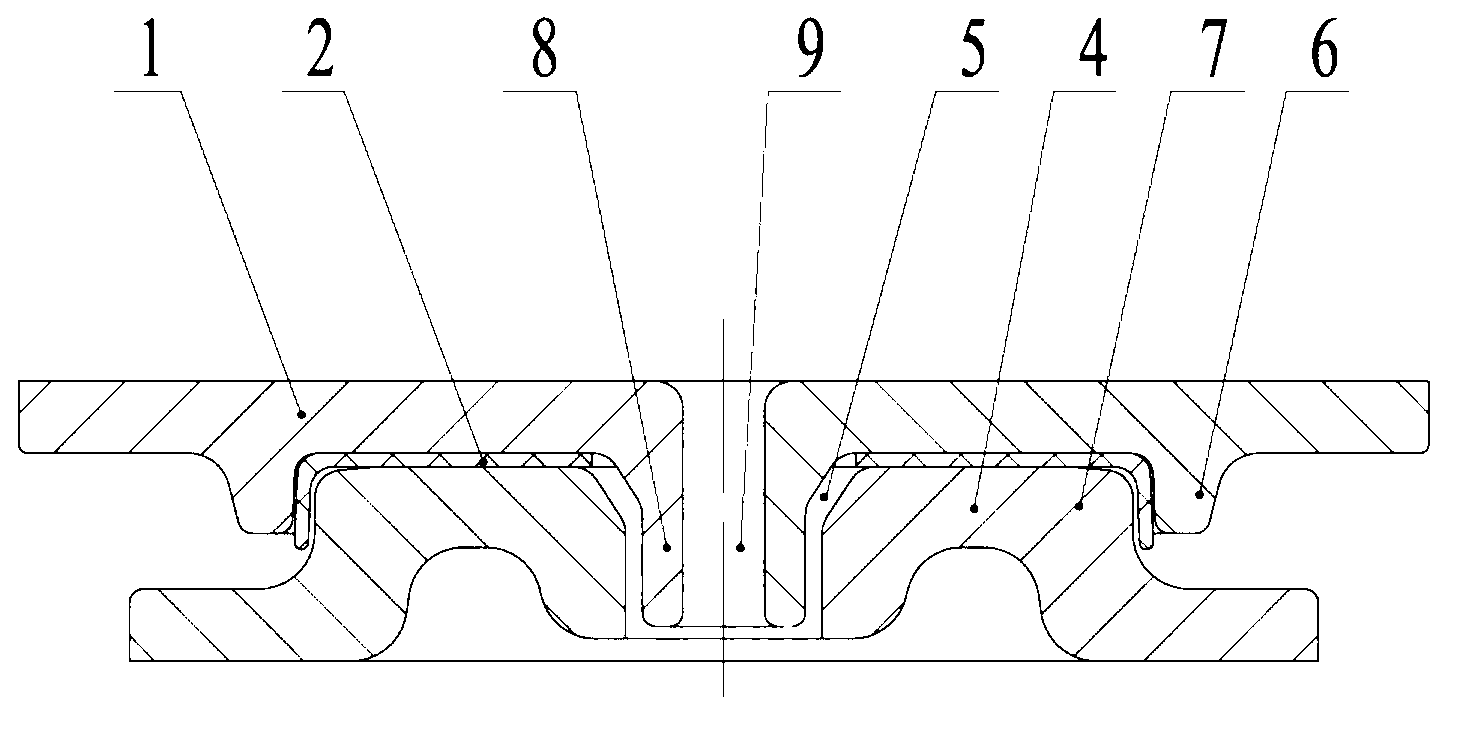

[0027] Embodiment 2, a kind of railway car anti-silting core plate structure, combined with figure 2 , including an upper center plate 1 and a lower center plate 4, the edge of the upper center plate 1 is provided with a protrusion I6, and the middle is a groove, the middle of the lower center plate 4 is provided with a protrusion II7, and the upper center plate 1 The groove cooperates with the protrusion II7 of the lower core plate 4. This structure can effectively prevent sand and water from entering and depositing in the lower core plate, and the requirements for manufacturing accuracy are not high. Between the groove of the upper center disc 1 and the protrusion II7 of the lower center disc 4, a center disc wear disc 2 with a central hole is provided, and the center disc wear disc 2 is used to avoid direct contact and wear of the upper center disc and the lower center disc, and Can provide slewing resistance torque. There is no flange around the wear disc of the center d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com