Rubber belt machine using single beam to support carrier roller group and maintenance walkway

A technology for supporting rollers and roller groups, applied in the directions of rollers, conveyors, supporting frames, etc., can solve the problems of long construction period, high difficulty and high cost, simplify the form of supporting structure, reduce engineering manufacturing costs, save energy The effect of the amount of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

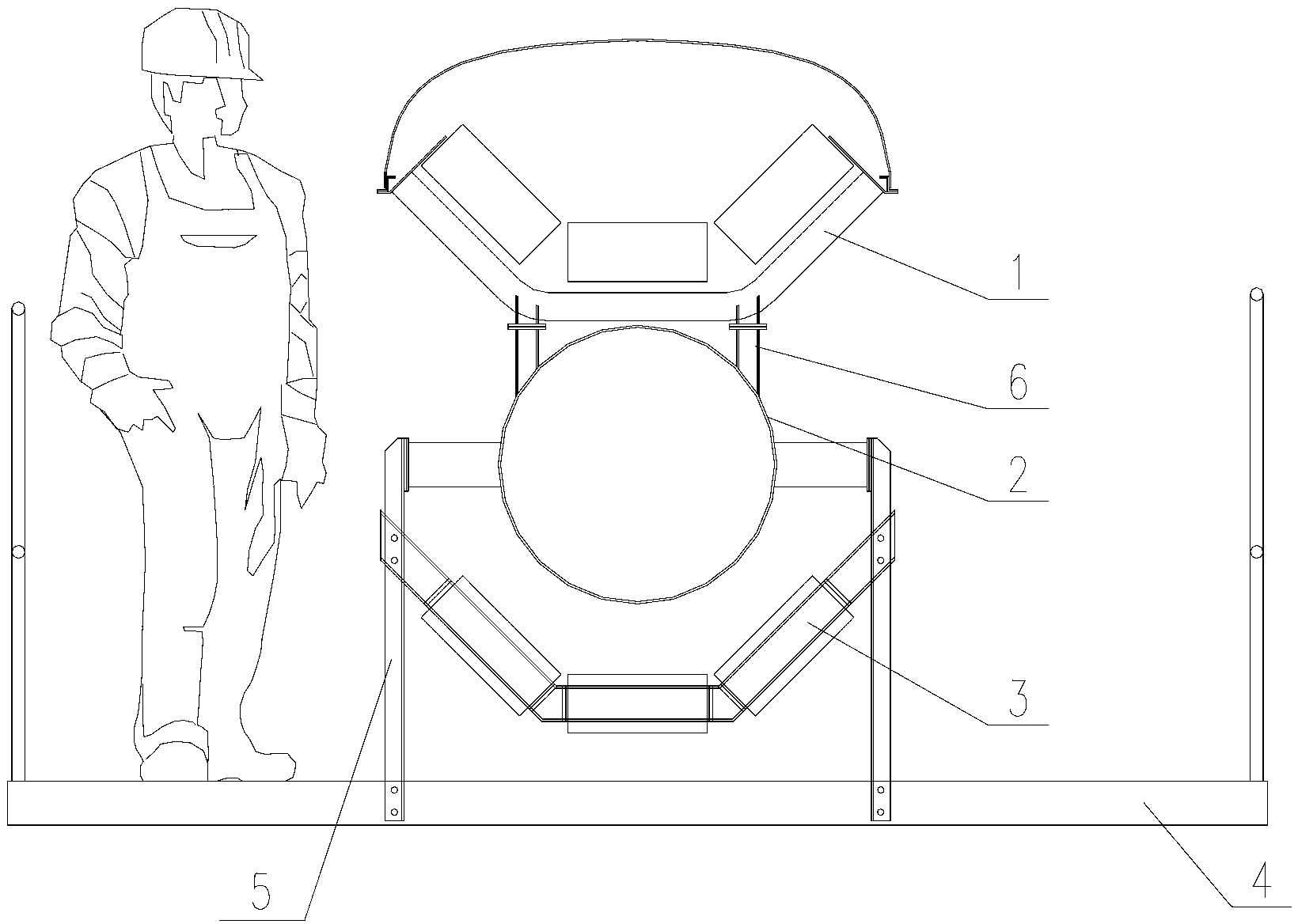

[0021] Embodiment 1 of the present invention: as figure 1 As shown, a tape machine using a single beam to support the idler group and the maintenance walkway, including the load bearing roller group 1, the support beam 2, the return idler group 3 and the maintenance walkway 4, the support beam 2 is provided with a support frame 5, The bottom of the support frame 5 is fixedly connected with the maintenance walkway 4, and the return idler group 3 is fixed on the support frame 5; The support beam 2 and the connecting rod 6 are welded and fixed together, and the connecting rod 6 and the carrying idler roller group 1 are connected together by bolts.

[0022] The cross-sectional shape of the support beam 2 is circular. The distance between any two adjacent support frames 5 on the support beam 2 is 3m. The distance between any two adjacent sets of idler rollers on the support beam is 1.2m.

[0023] Return idler group 3 adopts flat idler group. The return roller group 3 is fixed ...

Embodiment 2

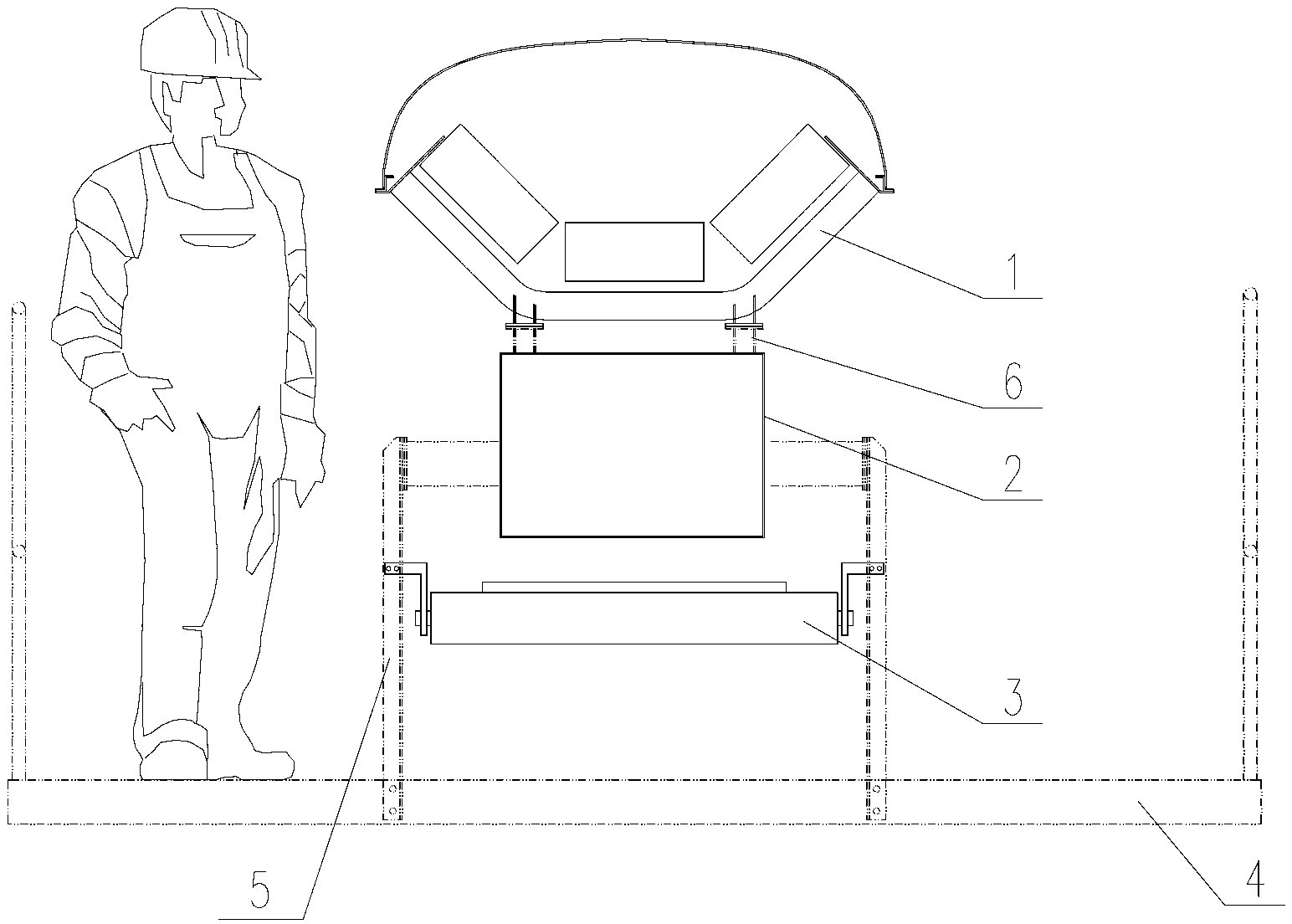

[0024] Embodiment 2 of the present invention: as figure 2 As shown, a tape machine using a single beam to support the idler group and the maintenance walkway, including the load bearing roller group 1, the support beam 2, the return idler group 3 and the maintenance walkway 4, the support beam 2 is provided with a support frame 5, The bottom of the support frame 5 is fixedly connected with the maintenance walkway 4, and the return idler group 3 is fixed on the support frame 5;

[0025] The support beam 2 and the connecting rod 6 are welded and fixed together, and the connecting rod 6 and the carrying idler roller group 1 are connected together by bolts. The cross-sectional shape of the support beam 2 is rectangular. The distance between any two adjacent support frames 5 on the support beam 2 is 8m. The distance between any two adjacent sets of idler rollers on the support beam is 4m.

[0026] The return roller group 3 adopts a V-shaped roller group. The return roller grou...

Embodiment 3

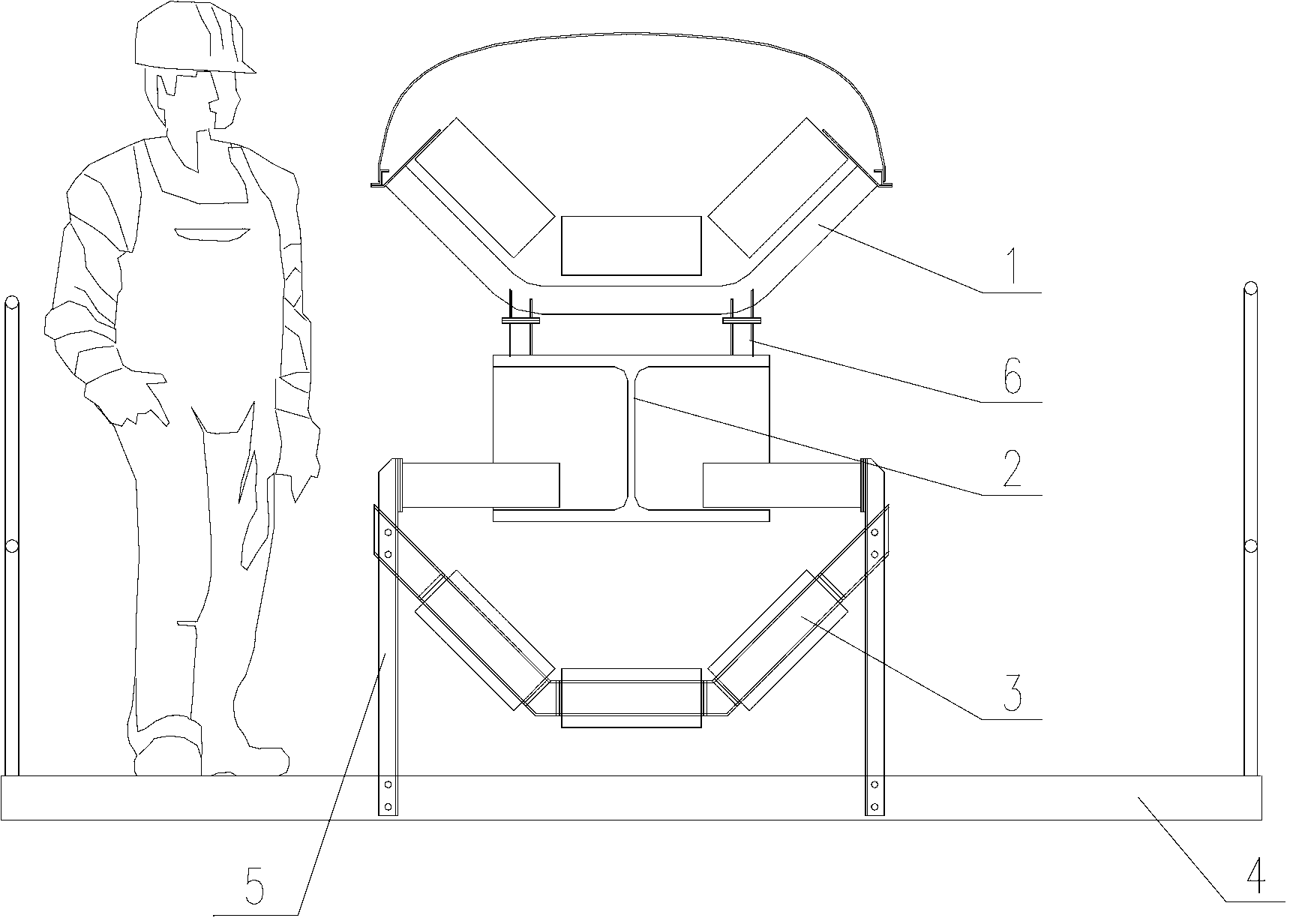

[0027] Embodiment 3 of the present invention: as image 3 As shown, a tape machine using a single beam to support the idler group and the maintenance walkway, including the load bearing roller group 1, the support beam 2, the return idler group 3 and the maintenance walkway 4, the support beam 2 is provided with a support frame 5, The bottom of the support frame 5 is fixedly connected with the maintenance walkway 4, and the return idler group 3 is fixed on the support frame 5; The support beam 2 and the connecting rod 6 are welded and fixed together, and the connecting rod 6 and the carrying idler roller group 1 are connected together by bolts.

[0028] The cross-sectional shape of the support beam 2 is I-shaped. The distance between any two adjacent support frames 5 on the support beam 2 is 12m. The distance between any two adjacent bearing roller groups on the support beam is 6m. The return idler group 3 adopts a grooved idler group. The return roller group 3 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com