Bridge crane and method for reducing carry-over quantity of vertical gold wire and gold-plated wire workpiece

A technology for bridge cranes and workpieces, which is applied in the direction of walking bridge cranes, cranes, transportation and packaging, etc. It can solve the problems of reducing the amount of belt out, not being able to reuse, and being unable to overcome surface tension, so as to reduce waste and loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

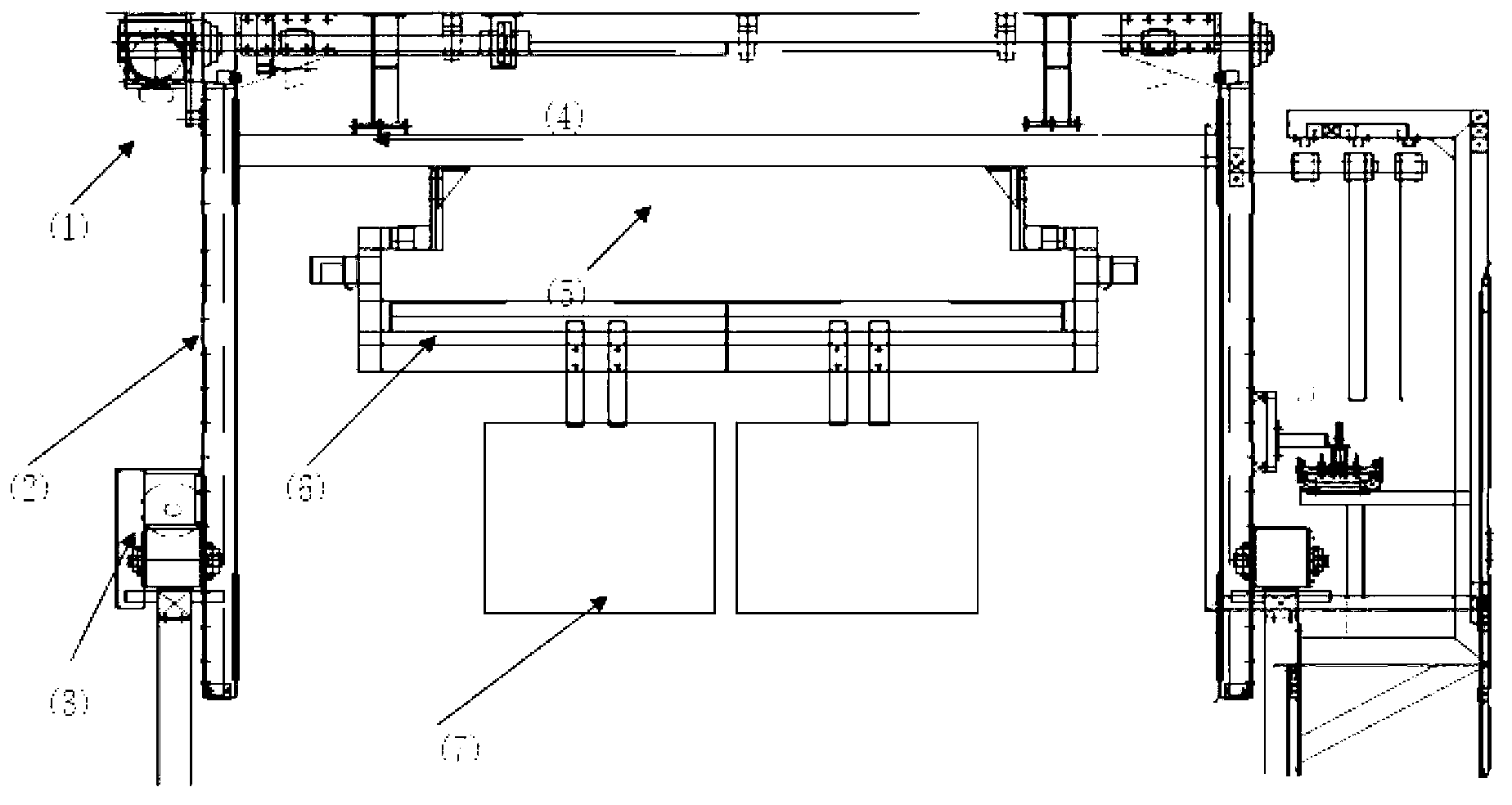

[0013] Such as figure 1 As shown, a bridge crane that reduces the amount of workpieces carried out by vertical gold wires and gold-plated wires includes a lifting motor 1, a main body support arm 2, a traverse motor 3, an upward lifting soft arm 4, a lifting beam 5 and a crane fly Bar 6; one end of the main body support arm 2 is connected with a traverse motor 3, and the other end is connected with a lifting motor 1, and the lifting motor 1 is connected with the uplifting soft arm 4, and the lifting soft arm 4 is fixed parallel to the lifting beam 5, and the lifting beam 5 is provided with a Skytrain Flying Bus 6.

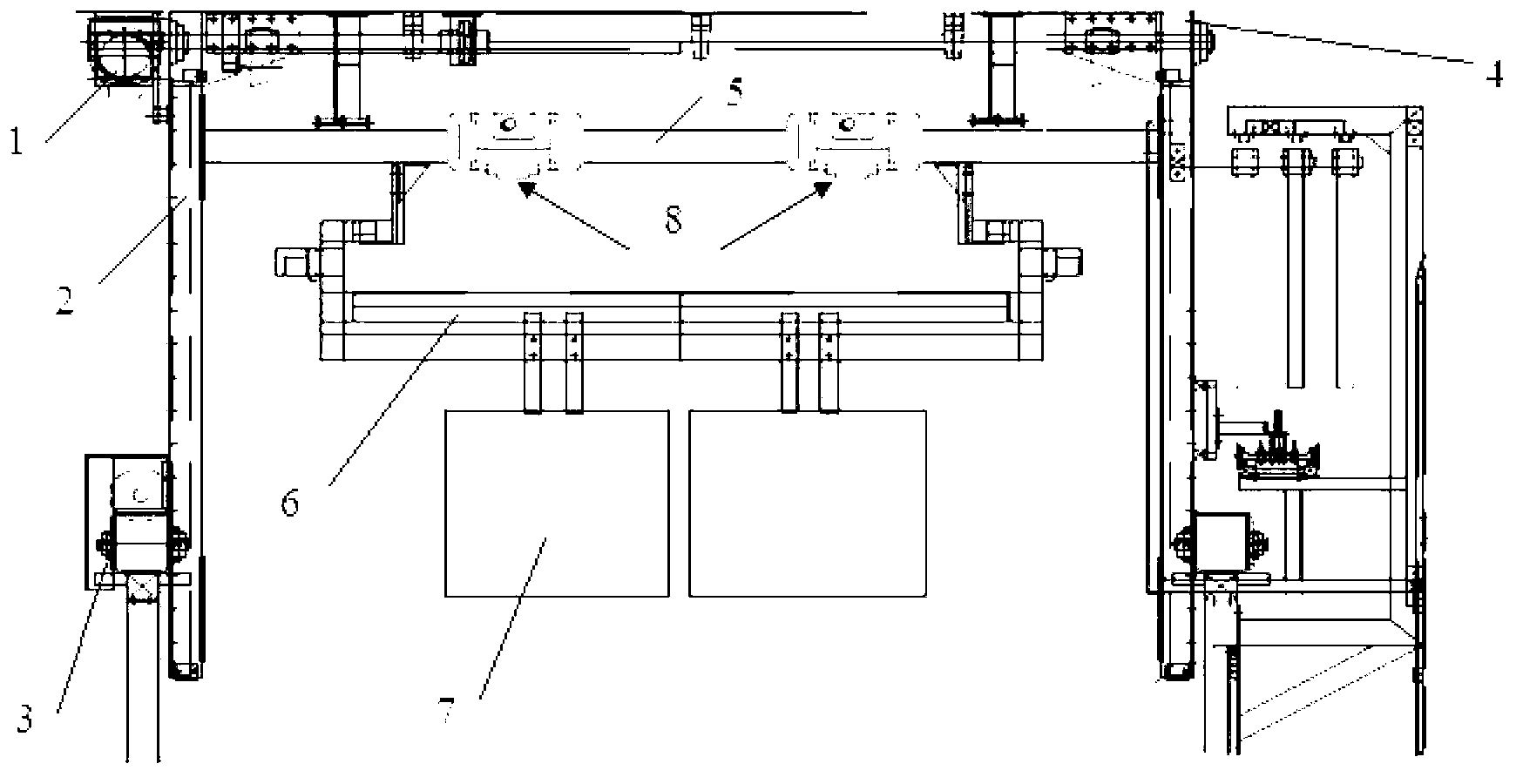

[0014] Such as figure 2 As shown, a vibration motor 8 is also arranged on the lifting beam 5 .

[0015] The number of the vibration motors 8 is 2; the power of the vibration motors 8 is 30W, the frequency is 50Hz, and the voltage input is 220V.

[0016] A method for reducing the amount of verticalized gold wire and gold-plated wire workpiece carry-over is as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com