Polycrystalline silicon ingot, manufacturing method thereof, solar cell

A technology of polycrystalline silicon ingots and manufacturing methods, which is applied in the direction of polycrystalline material growth, chemical instruments and methods, circuits, etc., and can solve problems such as many grain boundaries and dislocations, low photoelectric conversion efficiency, and low attenuation coefficient of polycrystalline silicon solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

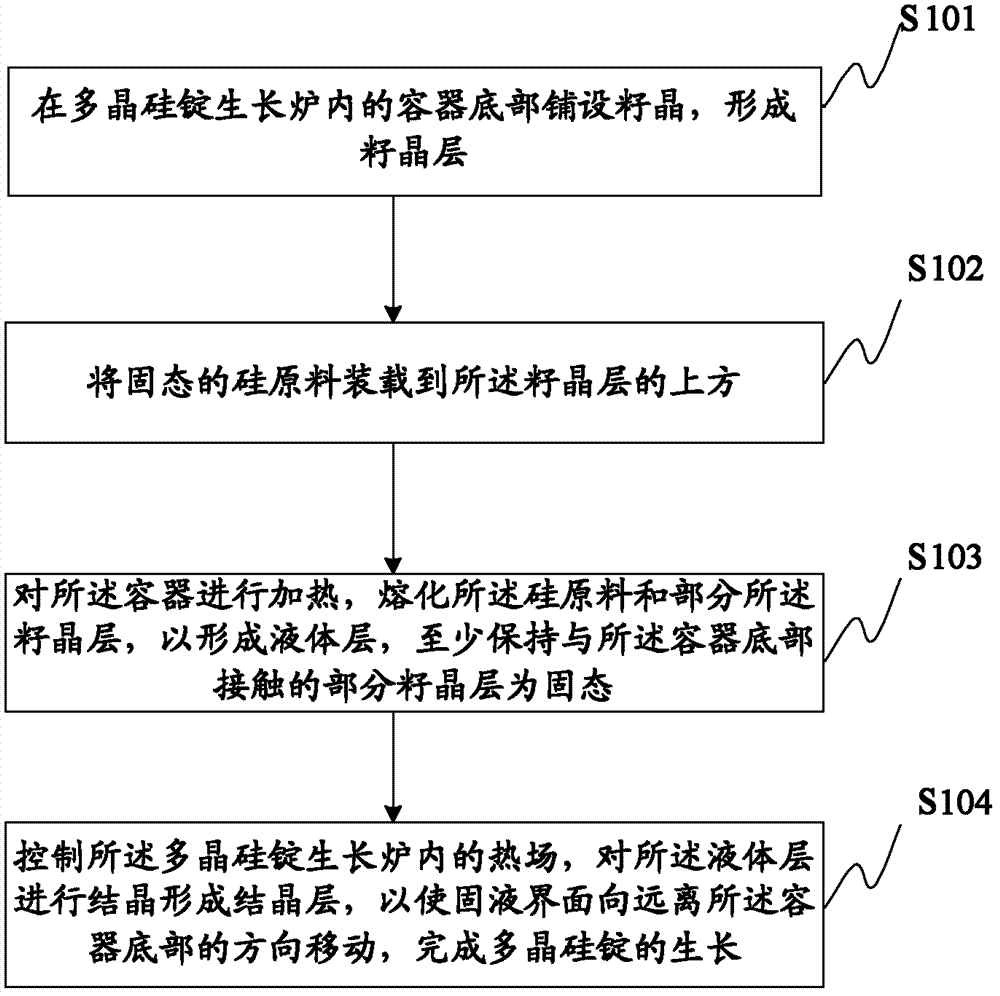

[0111] Based on the above research, an embodiment of the present invention provides a method for manufacturing a polycrystalline silicon ingot, the flow chart of the method is as follows figure 1 shown, including the following steps:

[0112] Step S101: laying seed crystals on the bottom of the container in the polycrystalline silicon ingot growth furnace to form a seed crystal layer;

[0113] Wherein, the seed crystal layer may be a whole large single crystal seed crystal which is substantially the same size and shape as the bottom of the container, or may be formed by splicing multiple small single crystal seed crystals. Moreover, the seed crystal is single crystal silicon with a fixed crystallographic orientation, and the seed layer includes at least one single crystal silicon layer with crystallographic orientation. Preferably, the seed crystals in this embodiment are (100), ( 110) or (111) oriented single crystal silicon.

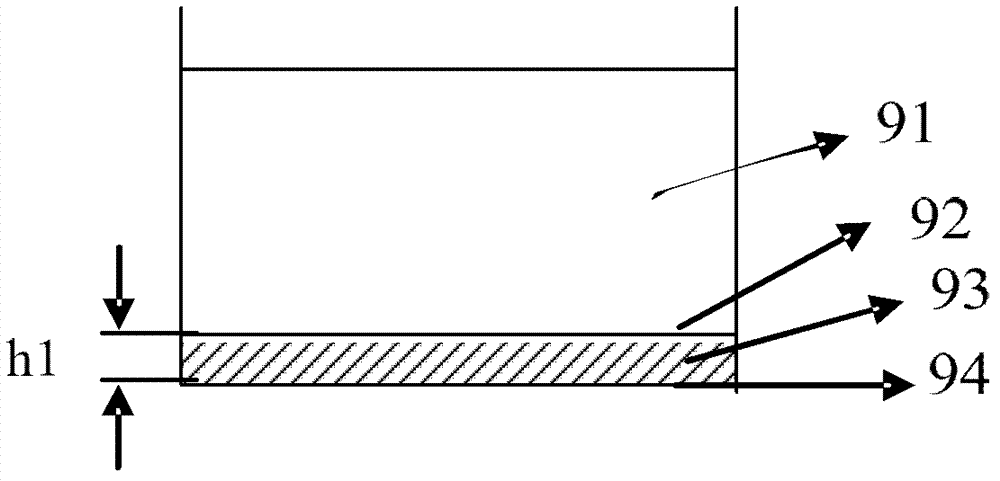

[0114] Specifically, in this embodiment, the s...

Embodiment 2

[0136] In the normal ingot casting process, after the crystal growth is completed, the crystal needs to be cooled to a certain temperature, the polysilicon ingot is removed from the ingot furnace, and then the polysilicon ingot is further processed.

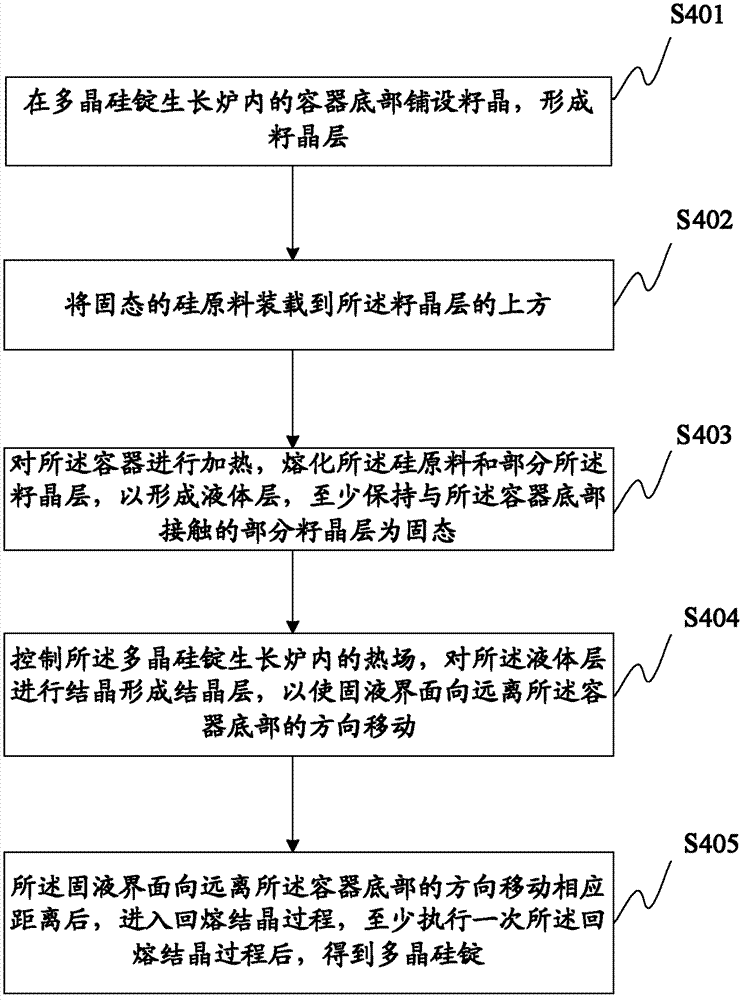

[0137] As described in step 104 in Example 1, the crystallization rate of molten silicon will affect the quality of the final product, and the hard spots and impurity-enriched layers in the product can be reduced by slowing down the growth rate, but due to the initial stage of crystallization , the growth rate of the crystal is more difficult to control, in order to avoid the above-mentioned defects, therefore, on the basis of the first embodiment, this embodiment figure 1 The process of completing the crystal growth in step S104 is further defined, and the specific process of forming the polycrystalline silicon ingot is described in detail.

[0138] see figure 2 In this embodiment, control the thermal field in the polysilicon ...

Embodiment 3

[0148] The flow chart of the method for manufacturing polycrystalline silicon ingots disclosed in this embodiment is shown in Figure 4. The difference from the above two embodiments is that in this embodiment, the selection of the seed crystal, the formation method of the seed crystal layer, and the method of loading the silicon raw material process concrete, Figure 4 Only the method in embodiment two is used as an example for illustration. Of course, the method in this embodiment can also be applied to the method in embodiment one. The method in this embodiment includes the following steps:

[0149] Step S201: at the bottom of the container in the polycrystalline silicon ingot growth furnace, the seed crystal layer is formed by splicing and tiling seed crystals with the same crystallographic orientation, and the seed crystal layer is substantially parallel to the bottom of the container;

[0150] In this embodiment, it is preferable to use (100)-oriented monocrystalline sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com