Method for filling deep soft foundation zero additional load bubble mixed lightweight soil subgrade

A technology of ground-zero addition and soil roadbed, which is applied in roads, roads, buildings, etc., can solve problems such as difficult handling of deep soft foundations, and achieve remarkable practicability and economy, strong bearing capacity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

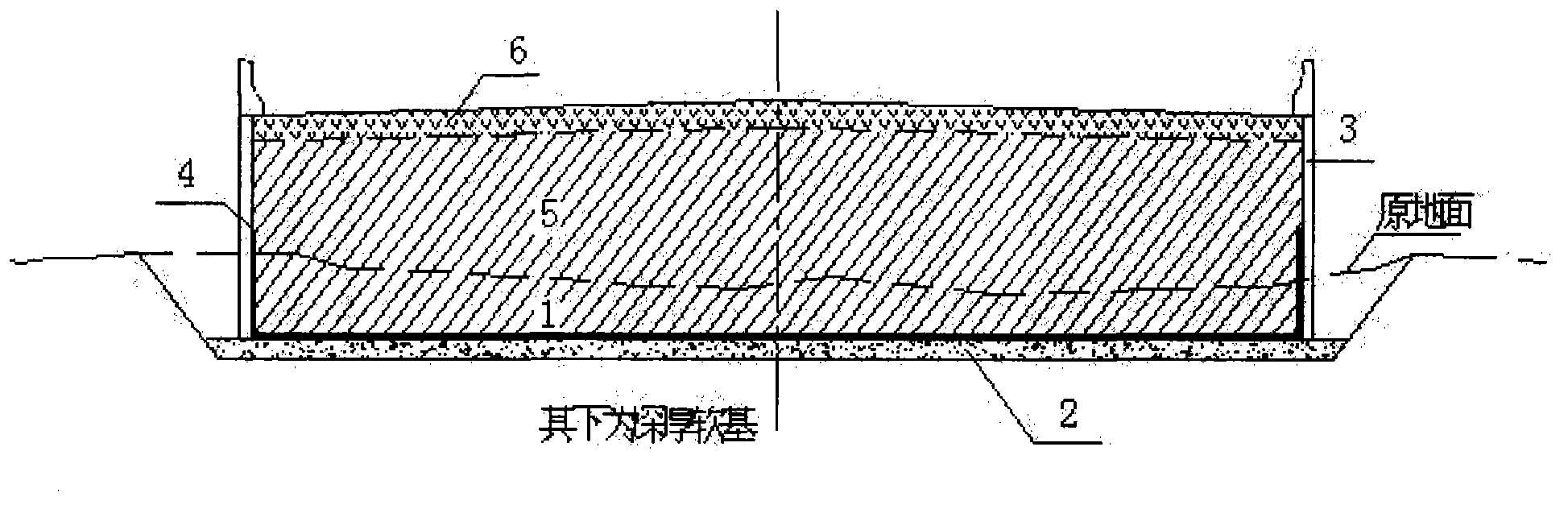

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0019] The present invention is mainly realized by utilizing the characteristics of air-bubble mixed light soil, which is a kind of closed porous light material with a bulk density of 4-12kN / m 3 , is only 1 / 5 to 3 / 5 of that of ordinary sandy soil roadbed filler, and the mass water absorption rate is not more than 20% under the pressure of 10 meters of water head.

[0020] figure 1 It is a structural schematic diagram of a deep soft foundation zero additional load air bubble mixed light soil subgrade in a specific embodiment of the present invention. Such as figure 1 As shown, firstly, according to the load generated by air bubble mixed light soil subgrade and pavement structure layer (including subgrade, road surface and vehicles), the foundation soil 1 of 1.1 to 1.3 times the weight of the load i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com