cp anode function and stress self-sensing integrated intelligent composite material

A composite material and nanocomposite material technology, applied in the field of CP anode function and stress sensing integrated intelligent composite material, can solve the problems of cathodic current delivery efficiency affecting CP system, insufficient structural protection of CP system, aging of anode material, etc. The effect of improving the resistance to erosion particles, reducing the permeability, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

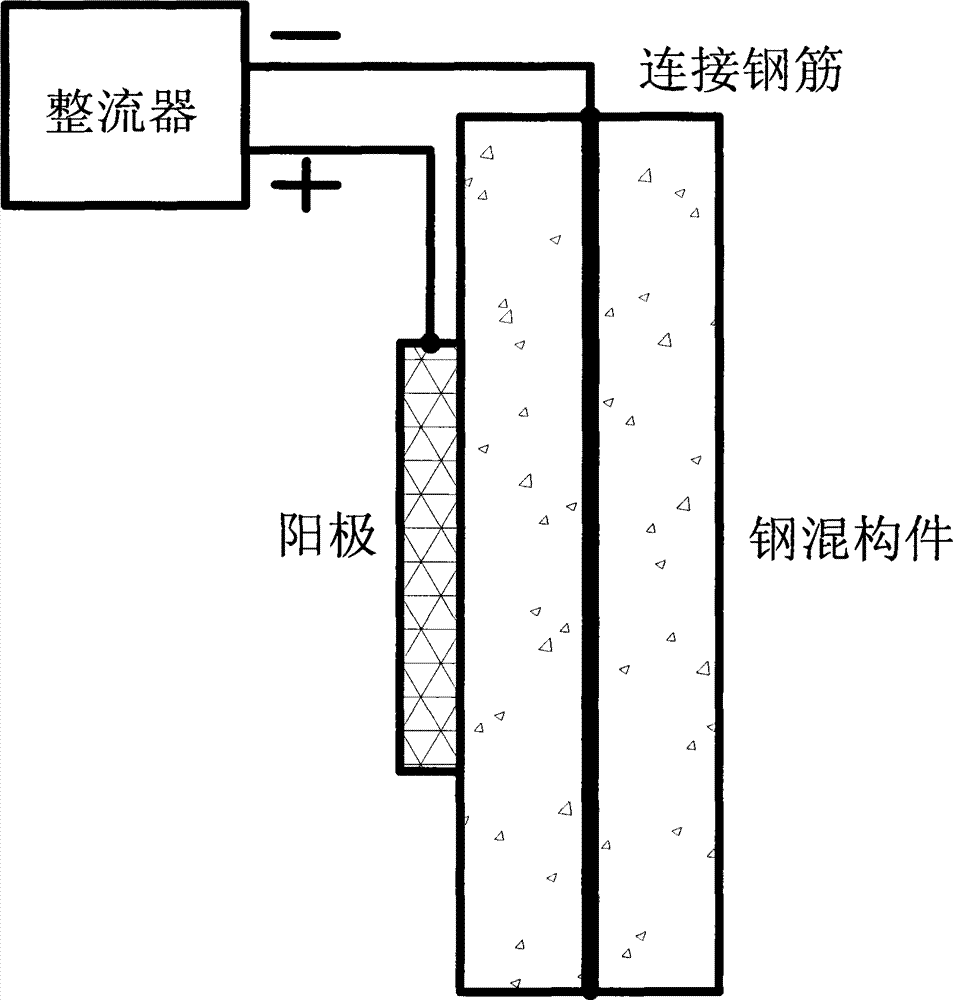

[0024] Construction of CP anode system

[0025] In the engineering structure, the overall structure of the CP system is as follows: figure 1 As shown, including anode material, steel cathode and rectifier system to apply electric field load. Before the anode system is laid out, it is necessary to evaluate the overall and local corrosion status of the structure based on the overall corrosion monitoring results of the structure, and delineate the areas that require corrosion control. Then, the anode system is laid out for the specific area. First, clean up the area where the anode needs to be laid, such as removing the contaminated concrete surface, or even replace severely deteriorated local components; second, re-concrete the treated components; third, repair concrete or other materials. The main anode of Ti slats is laid on the surface, and then coated with sprayed cement-based nano-composite materials. After the thickness reaches 0.5-1cm, the surface is pressed into the Ti...

Embodiment 2

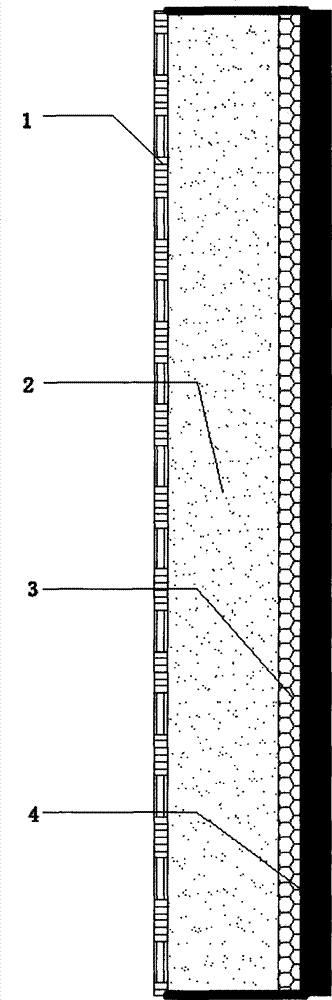

[0027] CP anode material composition and structure form

[0028] CP anode function and stress sensing integrated smart composite material structure such as figure 2 As shown, it generally includes a four-layer structure, the first layer is the main anode of Ti slats, the second layer is embedded Ti mesh, the third layer can spray cement-based nanocomposites, and the fourth layer is carbon fiber cloth. Among them, the main components of cement-based nanocomposites include polyacrylamide or PVA fibers, carbon fibers or carbon nanofibers, carbon nanotubes, carbon black particles or graphene, P.O. series cement, and pumping agents. Mix evenly according to the proportion, and use the traditional concrete pumping technology for construction, in which the weight ratio of water and cement-based nanocomposite is 0.4-0.6. A typical formulation used is as follows:

[0029] Table 1 Typical formula of smart composite materials

[0030]

[0031] Organic materials such as polyacrylami...

Embodiment 3

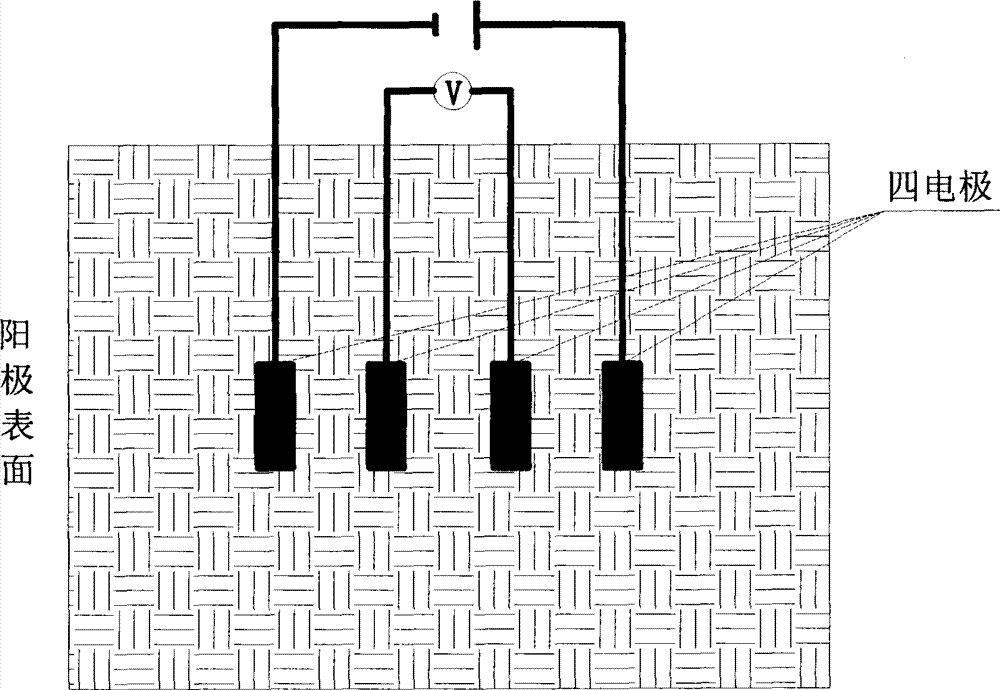

[0033] Four-electrode method for measuring stress state

[0034]During spraying of the CP anode with cement-based nanocomposites, the image 3 The four-electrode system shown. During the stress state test, the electrodes at both ends apply an electric field, and the changes in the conductivity of the concrete are measured through the two electrodes in the middle. Combined with the quantitative relationship curve between conductivity and strain, the corresponding relationship between conductivity and stress is obtained, so as to determine the structure of the location of the four electrodes. stress level.

[0035] The basic principle of the invention is the corrosion electrochemical activity of the material and the pressure-sensitive property of the cement-based smart material. The CP anode requires materials with high inertness to ensure that the anode current can be effectively delivered to the area where the structure needs to be protected. However, the high current densi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com