Fault detection method and device of reciprocating compressor

A fault detection and compressor technology, applied in pump testing, mechanical equipment, machines/engines, etc., can solve problems affecting efficient and economical operation, and achieve the effect of easy popularization and application, high accuracy, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

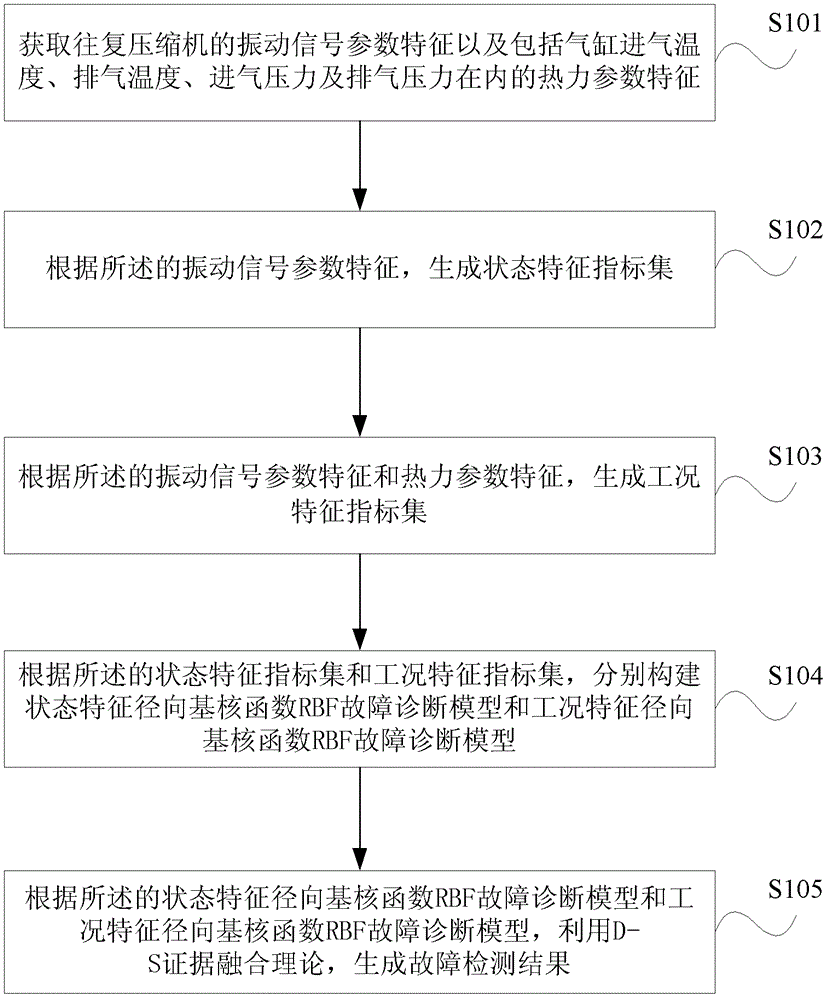

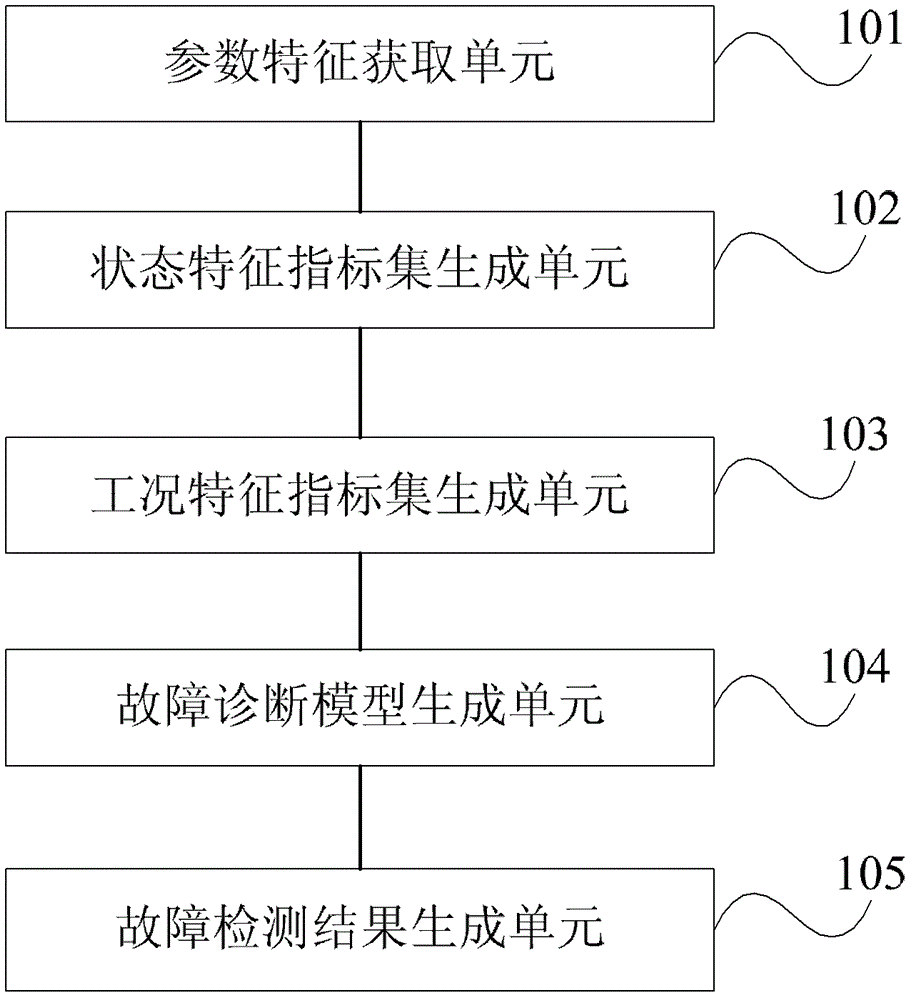

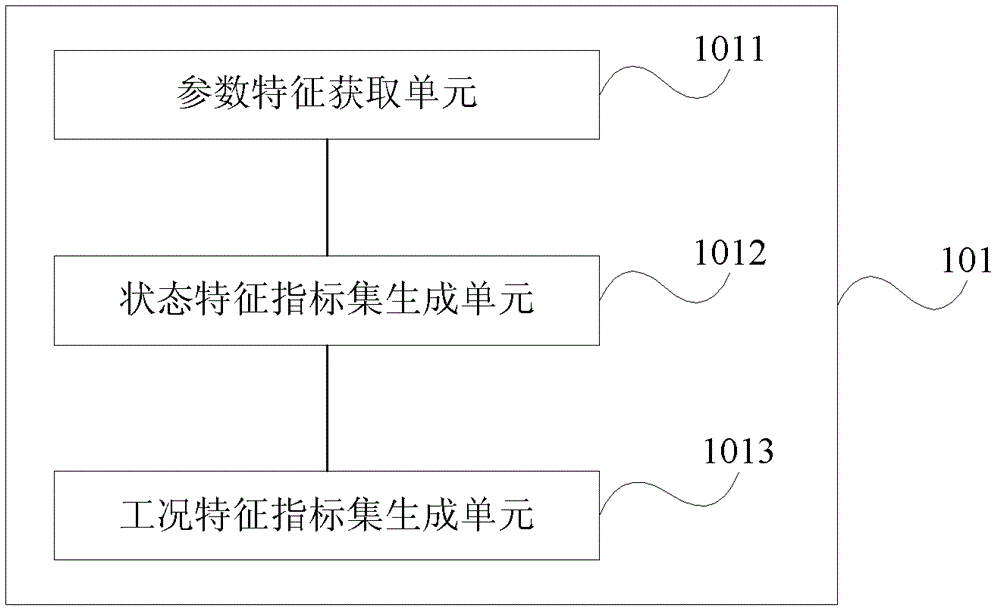

Method used

Image

Examples

specific Embodiment

[0077] In this embodiment, the research object is the gas valve of the reciprocating compressor, and its characteristic signals are collected by vibration, temperature and pressure sensors. Through the analysis of a large amount of monitoring data, the sample data of three typical states of the valve are selected, that is, the normal state (collected in October 2008, A machine with 2 cylinders and 1 intake valve), and the slightly worn state (collected in October 2008 , Machine A, 1 cylinder, 2 intake valves) and severe wear state (collected in October 2008, machine A, 1 cylinder, 1 intake valve), where each typical state contains 12 sets of sample data. For each set of sample data, its operating condition characteristic index set and state characteristic index set are respectively constructed as RBF neural network training samples, and then the operating condition characteristic RBF fault diagnosis model and state characteristic RBF fault diagnosis model are established.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com