Plasma concave-cavity flame stabilizer for engine

A plasma and burner technology, applied in the application field of aerospace power system, can solve the problems of narrow application range, self-excited oscillation, large cavity resistance, etc., and achieve enhanced injection fuel activity, rapid response and control, small price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

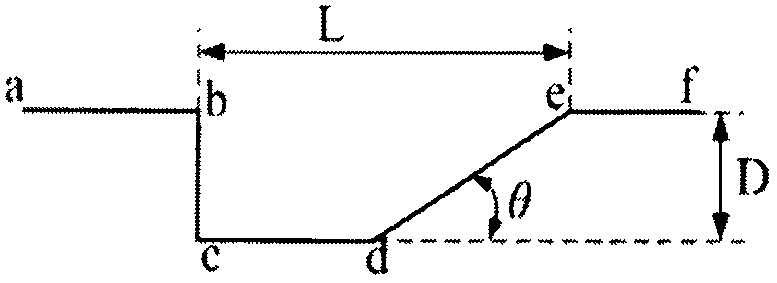

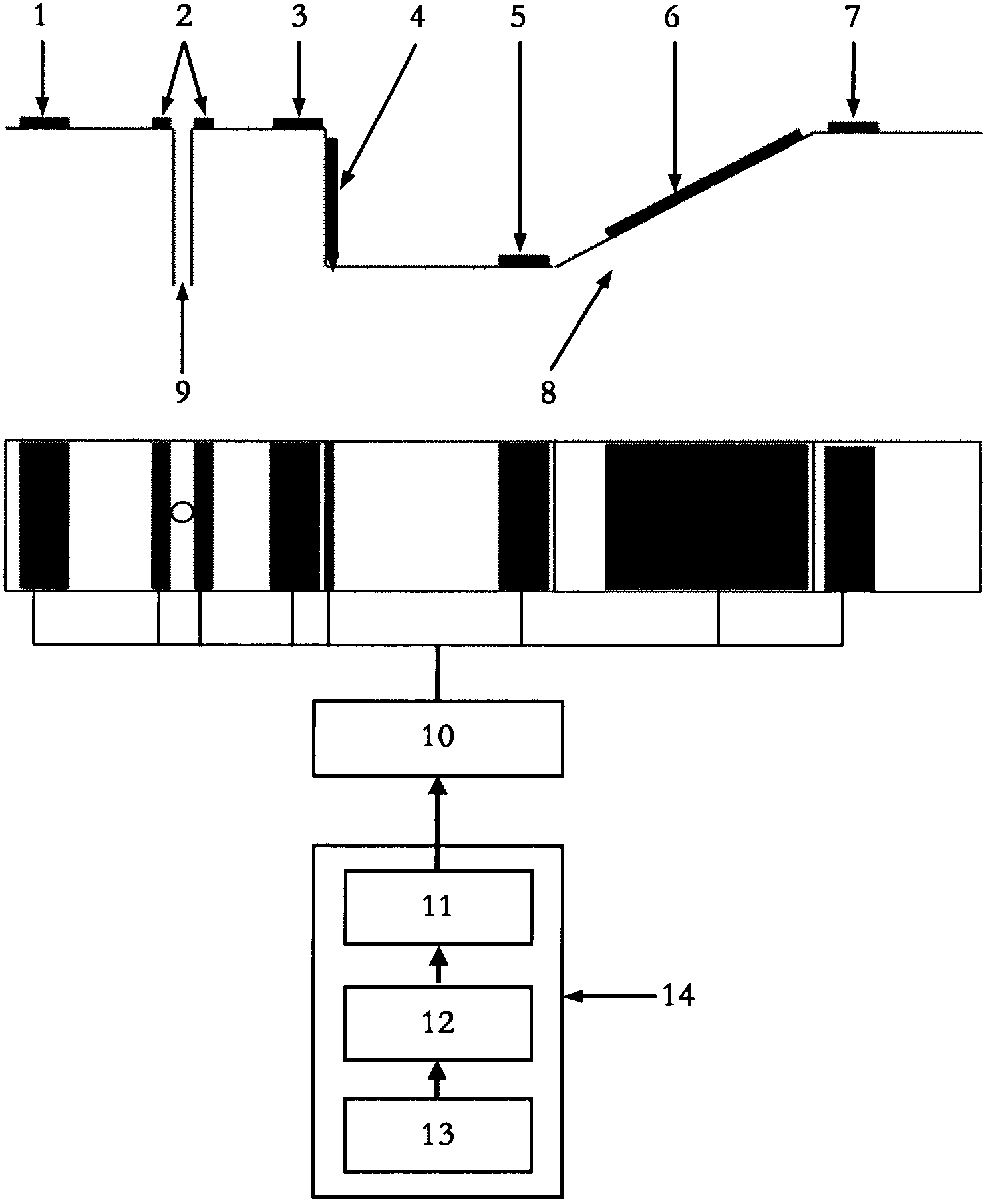

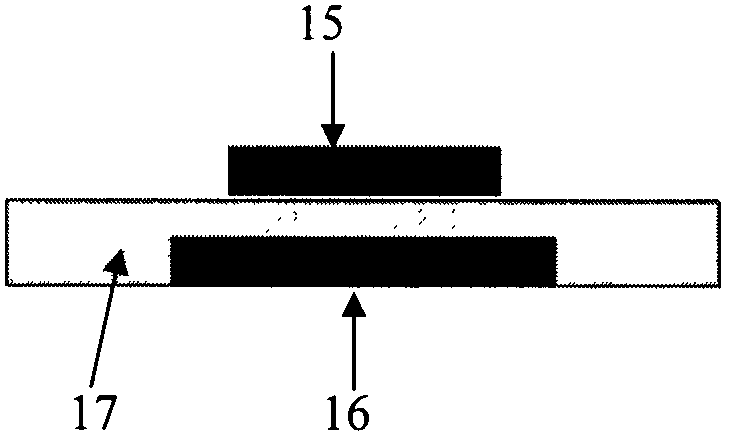

[0031] The engine plasma concave cavity burner of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. figure 2 A schematic structural diagram of the engine plasma cavity burner stabilizer of the present invention is given. The concave cavity flame stabilizer of engine plasma of the present invention comprises conventional concave cavity flame stabilizer, and described conventional concave cavity flame stabilizer comprises upstream ab, concave cavity body bcde and downstream ef (see figure 1 ), figure 1 A schematic diagram of the structure of a conventional concave flame holder is given, the upstream ab, the front wall of the cavity bc and the bottom cd of the cavity form a backward step, the bottom cd of the cavity, the rear wall de and the downstream ef form a forward step, and the front wall bc , the bottom wall cd and the rear wall de constitute the concave cavity body bcde, and the angle between the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com