Semi-welded plate heat exchanger

A plate heat exchanger and heat exchanger technology, which is applied in indirect heat exchangers, heat exchanger types, welding equipment, etc. Inconvenient disassembly and cleaning, etc., to achieve the effect of improving dirt resistance, small footprint and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

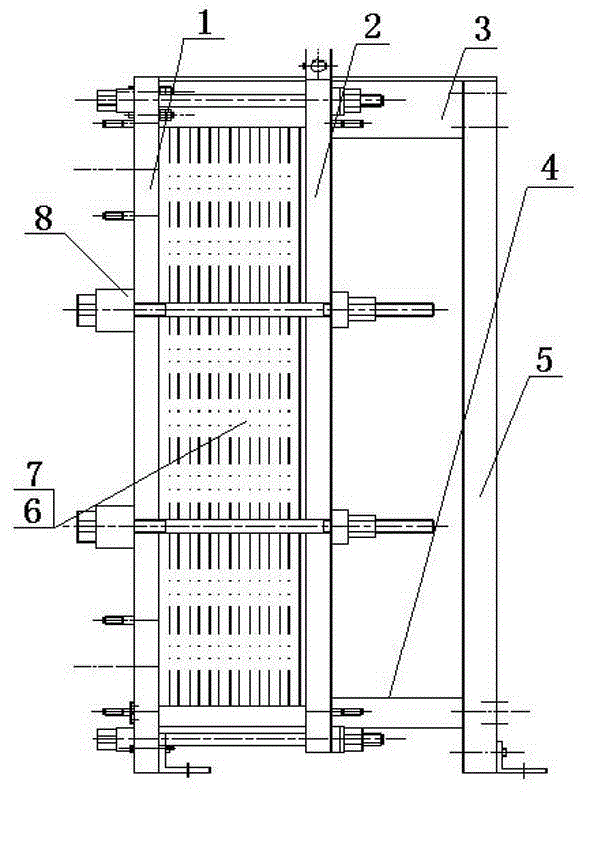

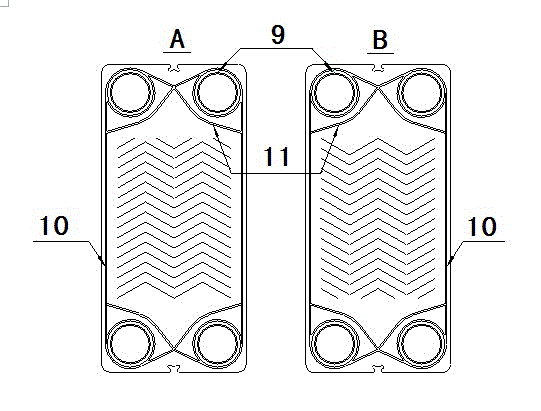

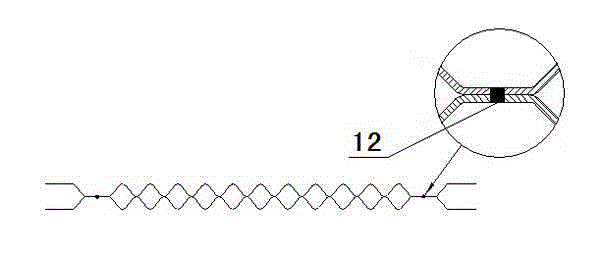

[0040] attached by figure 1 , 2 , 3: the heat exchanger includes a fixed clamping plate 1, a movable clamping plate 2, an upper guide rod 3, a lower guide rod 4, a pillar 5, a pair of semi-welded plates 6, a sealing gasket 7 and clamping bolts Pair 8, the fixed clamping plate 1, the movable pressing plate 2, the upper guide rod 3, the lower guide rod 4, and the pillar 5 constitute the frame of the heat exchanger, and a plurality of semi-welded plate pairs 6 pass through the sealing gasket 7 Assembled together to form a plate bundle, the plate bundle is arranged between the fixed clamping plate 1 and the movable clamping plate 2, and is fixed by the clamping bolt pair 8; between a plurality of semi-welded sheet pairs 6 on the plate bundle The seal is sealed by the sealing gasket 7, and at the same time, the sealing part 12 between the two plates A and B of the semi-welded plate pair 6 adopts a double-sided laser welding structure, which effectively overcomes the deformation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com