Method for deleting abnormal measuring data points in reverse engineering

A technology for measuring data and abnormal points, which is applied in the field of eliminating abnormal three-coordinate measurement data points, can solve problems such as data distortion, wrong probe contact parts, and sudden changes in the measurement environment of measurement equipment calibration parameters, so as to improve accuracy and model reconstruction. Ease of work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

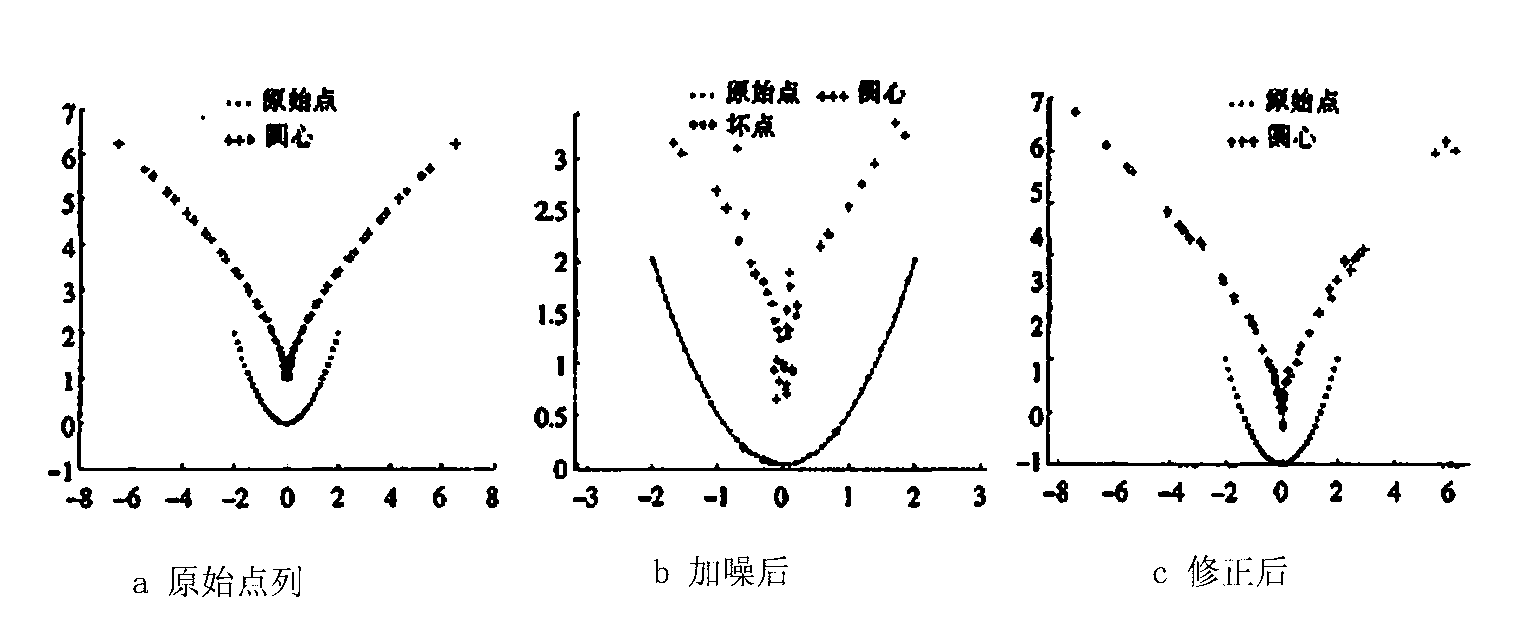

[0031] Embodiment 1, the present invention takes points on a section of parabola and lists as attached image 3 In attached drawing a (shown by dots in the figure), the "+" in the attached drawing shows a series of center positions corresponding to the dot row. The results after adding random noise to the data point column are shown in the appendix image 3 In the attached drawing b, it can be seen from the figure that after adding random noise, the change of the center position is more obvious. Use the algorithm of this paper to correct the position. The dots in the attached figure show the position of the data point, and the position shown by "*" is the corrected position of the abnormal point after the algorithm of this paper. The algorithm proposed by the present invention is used repeatedly, and the threshold is gradually reduced as required, so as to achieve a more ideal position correction. attached image 3 Figure c in the figure shows the data points after applying...

Embodiment 2

[0032] Embodiment 2, with Figure 4 Figure a in the middle is part of the point cloud of the car surface scanned by the three-coordinate measurement system. The point cloud contains abnormal points (noise points) that make the contour boundary unclear. Attached Figure 4 Figure b in the middle is the point cloud of the car surface collected by the algorithm of the present invention. It can be seen that most of the abnormal points have been eliminated, and the outline is relatively clear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com