Thermal shock test system

A test system and thermal shock technology, applied in the detection field, can solve the problems of no toxic and harmful waste gas treatment, retrieved waste gas treatment technology, toxic and harmful waste gas, etc., and achieve the effect of good dynamic response, light weight and high degree of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

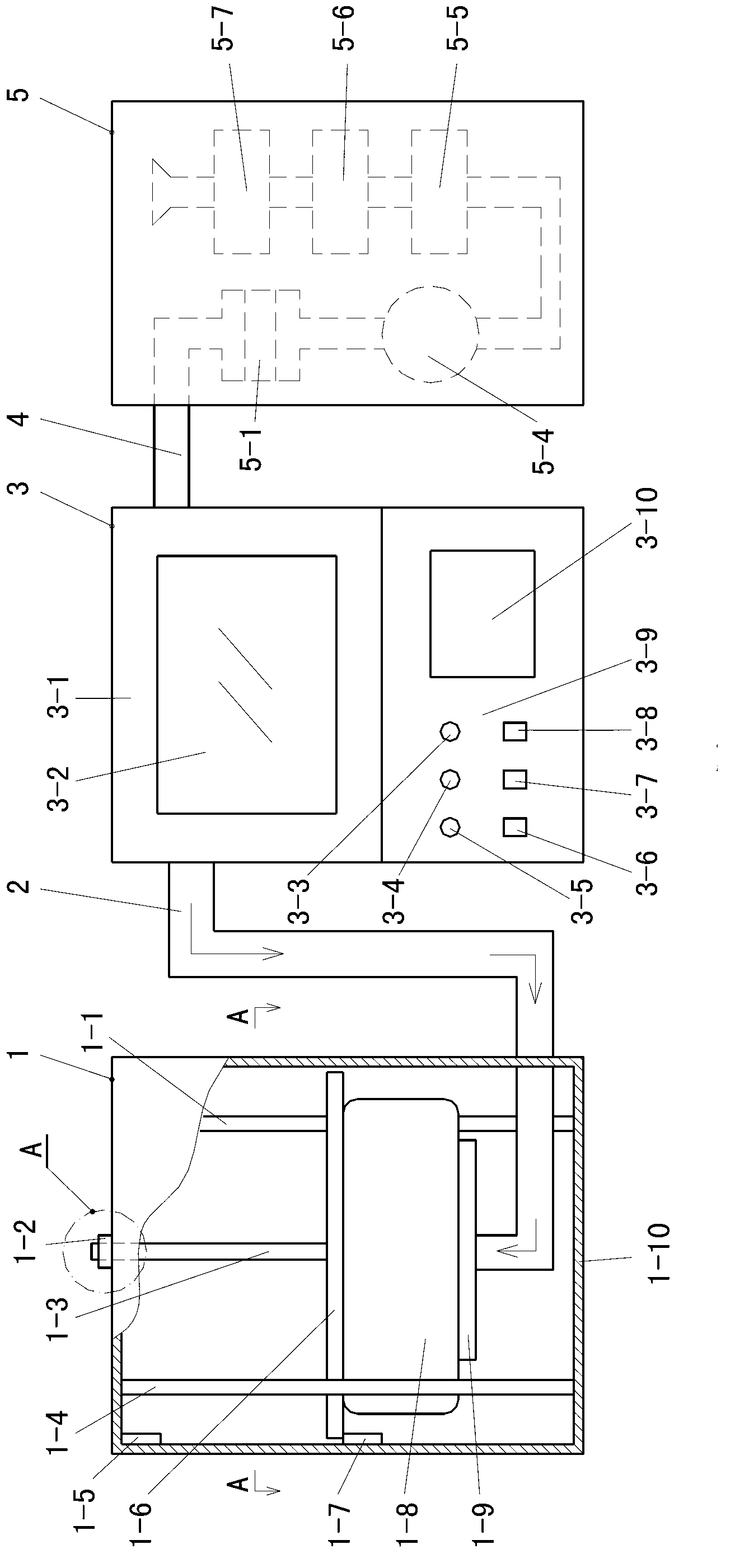

[0187] This embodiment combines figure 1 , Figure 15 and Figure 16 Be explained.

[0188] figure 1 Part of the label description: 1 is the waste gas storage tank; 2 is the first pipeline; 3 is the high temperature test chamber; 4 is the second pipeline; 5 is the waste gas filter box.

[0189] The high-temperature test box 3 has a mechanical structure with good sealing performance, thermal insulation performance and explosion-proof performance. The high temperature test chamber 3 has two functional areas, the upper and the lower.

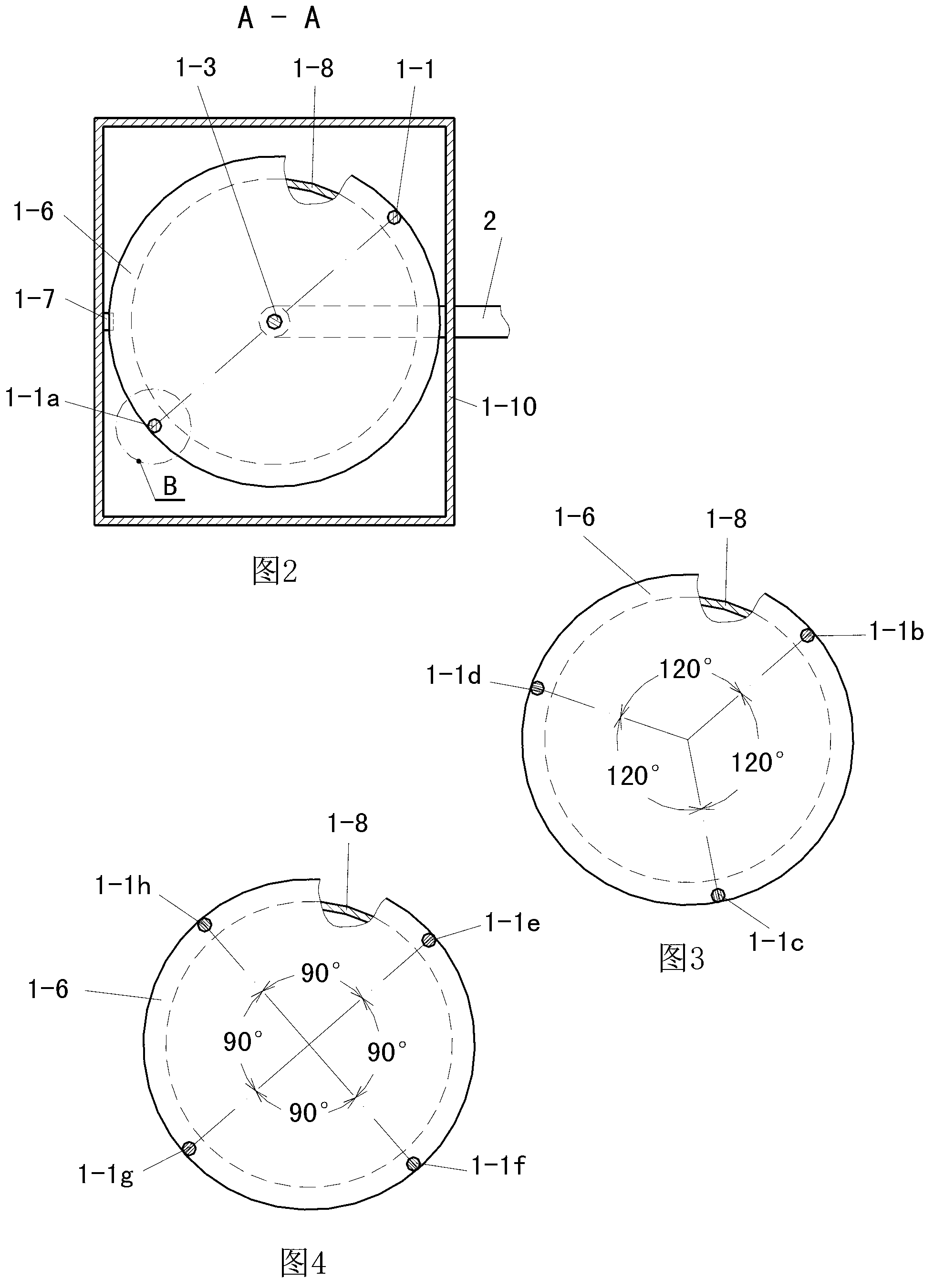

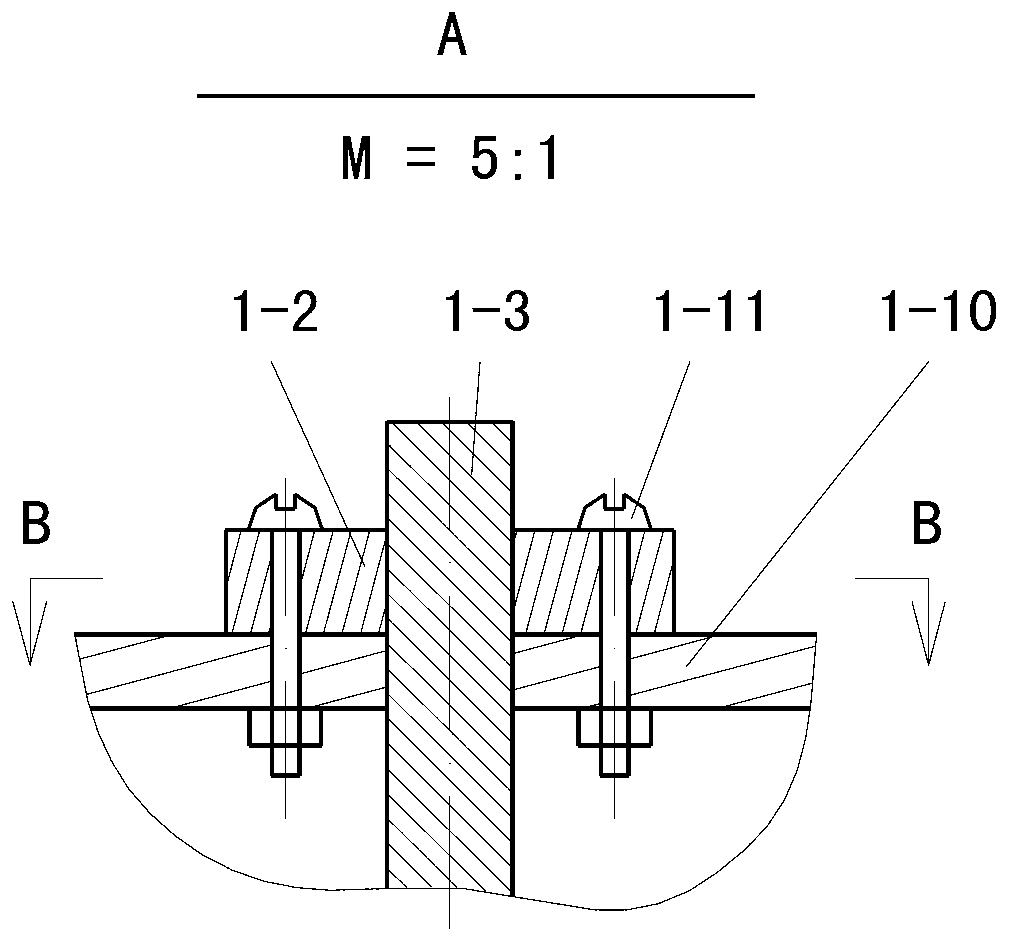

[0190] In the functional area of the lower part, a control panel 3-9 is installed at its front position, and an automatic control circuit is installed inside it. The automatic control circuit takes the single-chip microcomputer as the core, that is, the automatic control circuit adopts the control technology of the computer, and the software program required by the system of the present invention has been input into the inside of the single-...

Embodiment 2

[0205] In embodiment one, following action is arranged: "When pressing down side limit switch 1-7 again from counterweight plate 1-6, the software program of computer starts counting, and when the pre-set time expires, automatic The control circuit instructs the solenoid valve 3-15 to turn on the driving power, the solenoid valve 3-15 is opened, and new air enters."

[0206] Now, the above action is modified as follows: when the counterweight plate 1-6 presses the lower limit switch 1-7 again, the automation control circuit immediately instructs the solenoid valve 3-15 to turn on the driving power, and the solenoid valve 3-15 opens , new air enters.

Embodiment 3

[0208] In the first embodiment, the high temperature test chamber 3 has two functional areas, the upper and lower; in the third embodiment, the two functional areas are separately separated and set as the high temperature test chamber 3 and the control box.

[0209] The details of the high temperature test box 3 and the control box of the present embodiment are as follows.

[0210] The control box is equipped with a control panel at its front position, and an automatic control circuit is installed inside it. The automatic control circuit takes the single-chip microcomputer as the core, that is, the automatic control circuit adopts the control technology of the computer, and the software program required by the system of the present invention has been input into the inside of the single-chip microcomputer and has been debugged; computer.

[0211] The high temperature test chamber 3 is provided with a high temperature test chamber 3-13, and the tested test sample is placed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com