A reflective color filter

A color filter, reflective technology, used in optics, optical components, instruments, etc., can solve the problems of high operator and environmental hazards, less reflective color filters, etc., to achieve insensitive color changes, reflection The effect of low rate and improved color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

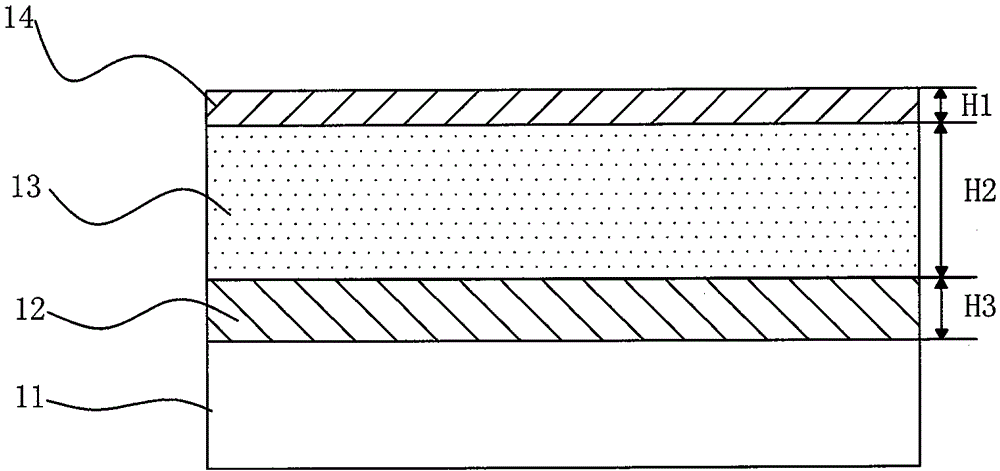

[0029] 31 is the flexible material PET or PC, 32 is aluminum, 33 is PMMA, 34 is nickel and 35 is PMMA.

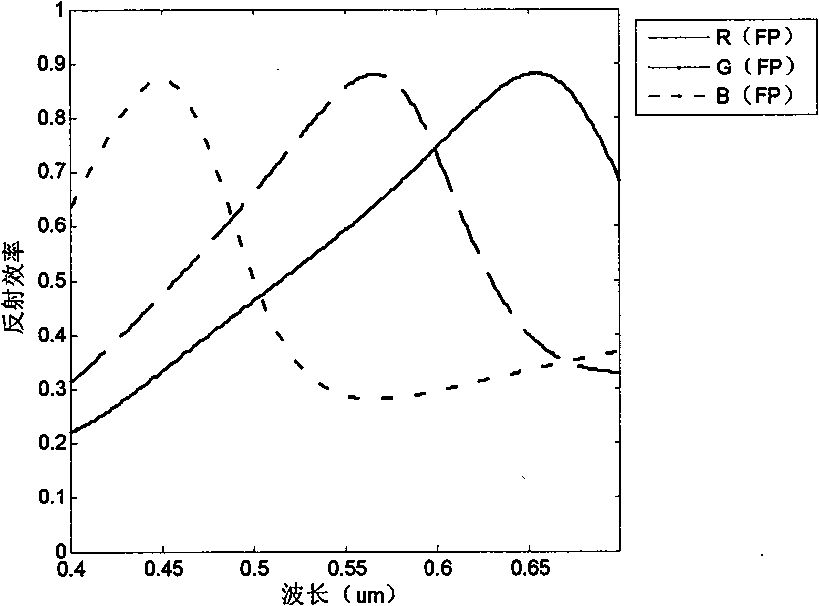

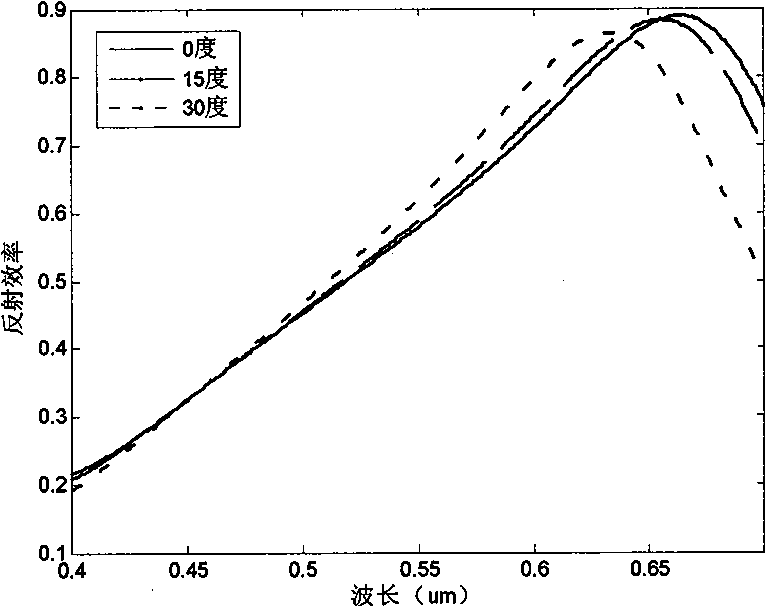

[0030] The structural parameters are designed for red, green and blue reflective color filters. Red: p=0.3um, F=0.3, h1=0.03um, h2=0.2um, h3=0.4um, h4=0.02um, h5=0.4um; Green: p=0.35um, F=0.5, h1=0.03 um, h2=0.18um, h3=0.35um, h4=0.01um, h5=0.35um; blue: p=0.35um, F=0.5, h1=0.03um, h2=0.14um, h3=0.29um, h4 =0.01um, h5=0.25um. The reflection characteristics and angle sensitivity of the filter were analyzed by rigorous coupled wave theory (RCWA). TM polarized light is incident from the top of the structure at an angle ranging from 0° to 30°.

[0031] Figure 5 Among them, R(FP), G(FP), and B(FP) represent the reflection of red, green, and blue TM light based on the traditional Fabry-Perot (FP) cavity structure reflective color filter, respectively. Efficiency vs. incident wavelength plot. Figure 5 Among them, R, G, and B respectively represent the relationship diagrams...

Embodiment 2

[0034] Adjust the period p of the wire grid, and observe the influence of period change on the reflection characteristics of the filter. Take the red filter as an example. p=0.3um, F=0.3, h1=0.03um, h2=0.2um, h3=0.4um, h4=0.02um, h5=0.4um. The reflective properties of the filter are analyzed by rigorous coupled wave theory (RCWA). TM polarized light is incident from the top of this structure, and the incident angle of this light is 0 degrees. from Figure 7 It can be seen that the period has an impact on the reflection peak position and bandwidth, but the impact is very small.

Embodiment 3

[0036] Adjust the duty ratio F of the wire grid, and observe the influence of the duty ratio change on the reflection characteristics of the filter. Take the red filter as an example. p=0.25um, h1=0.03um, h2=0.2um, h3=0.4um, h4=0.02um, h5=0.4um. The reflective properties of the filter are analyzed by rigorous coupled wave theory (RCWA). TM polarized light is incident from the top of this structure at an incident angle of 0 degrees. from Figure 8 It can be seen that the duty ratio has an impact on the reflection peak position and bandwidth, but the impact is very small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com