Preparation method of hybrid-structure solar cell

A solar cell and hybrid structure technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult promotion and low photoelectric conversion efficiency, and achieve the effects of simplifying the preparation process, easy to popularize in a large area, and less structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

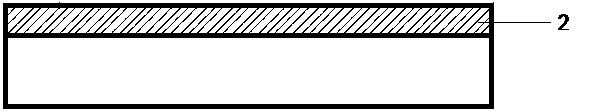

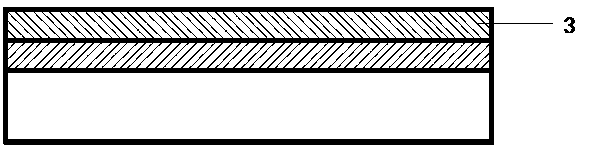

[0033] Such as Figure 1-6 Shown, a kind of preparation method of hybrid structure solar cell comprises the steps:

[0034] a. In the MOCVD or MBE reaction system, prepare the bottom doped film 2 on the surface of the substrate 1 at the preparation temperature of the bottom doped film 2;

[0035] b. In the MOCVD or MBE reaction system, prepare the upper layer doped film 3 on the surface of the bottom layer doped film 2 at the preparation temperature of the upper layer doped film 3;

[0036] c. Spin-coat metal catalyst particles on the surface of the upper doped film 3 or prepare catalyst particles 4 on the surface of the upper doped film 3 by using metal thin film annealing technology;

[0037] There are two methods for preparing catalyst particles 4 in this step:

[0038] One is, after the MOCVD reaction system drops to room temperature, take out the substrate prepared with the bottom layer and the upper layer film from the MOCVD reaction system, and spin-coat a layer of me...

Embodiment 1

[0052] The preparation of InP homogeneous hybrid structure solar cells based on InP substrates, the specific steps are as follows:

[0053] a. In the MOCVD reaction system, adjust the temperature of the reaction system to the preparation temperature required for the underlying doped film, and start supplying p-type doped zinc (Zn) source, indium (In) source, phosphorus (P) source and other reactants The bottom p-type doped InP thin film is prepared.

[0054] b. After 500 seconds, stop supplying various reactants. Adjust the temperature of the reaction system to the preparation temperature required for the upper-layer doped film, and start supplying n-type doped silicon (Si) source, indium (In) source, phosphorus (P) source and other reactants for the upper-layer n-type doped InP film preparation.

[0055] c. After 300 seconds, stop supplying various reactants. After the MOCVD reaction system drops to room temperature, the InP substrate prepared with the bottom and upper fil...

Embodiment 2

[0060] The preparation of heterogeneous hybrid structure solar cells based on germanium (Ge) substrates, the specific steps are as follows:

[0061] a. In the MOCVD reaction system, adjust the temperature of the reaction system to the preparation temperature required for the underlying doped film, and start supplying p-type doped zinc (Zn) source, indium (In) source, phosphorus (P) source and other reactants The bottom p-type doped InP thin film is prepared.

[0062] b. After 300 seconds, stop supplying various reactants. Adjust the temperature of the reaction system to the preparation temperature required for the upper-layer doped film, and start supplying n-type doped silicon (Si) source, indium (In) source, gallium (Ga) source, phosphorus (P) source and other reactants for the upper layer n-type doped In x Ga 1-x Preparation of P thin films.

[0063] c. After 400 seconds, stop supplying various reactants. After the MOCVD reaction system dropped to room temperature, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com