Printed Yagi antenna of vibrator loading type balance microstrip line feed

A technology for balancing microstrip lines and Yagi antennas, applied in antennas, antenna grounding switch structural connection, electrical components, etc., can solve problems such as large size, achieve size reduction, reduce size, and facilitate operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

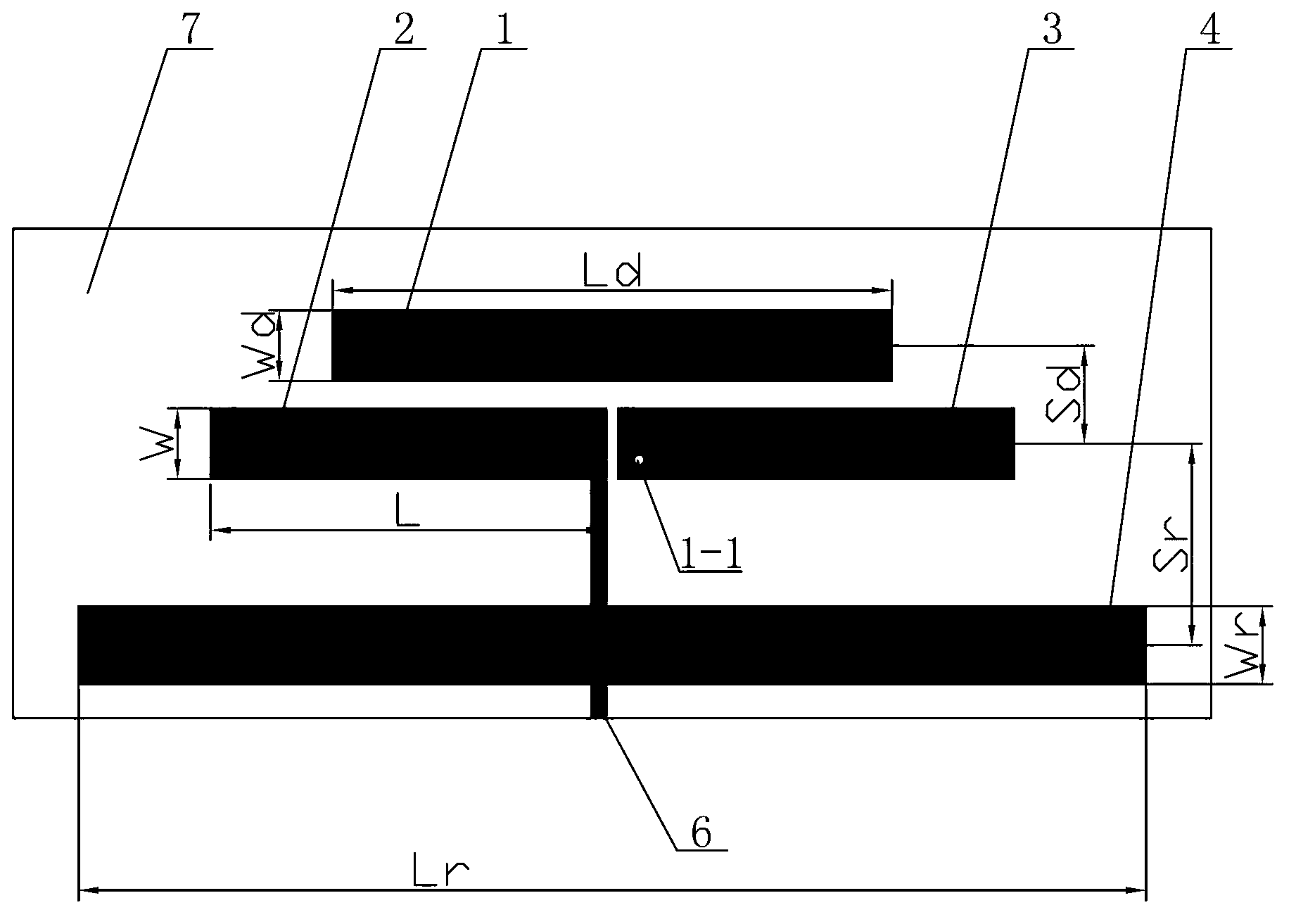

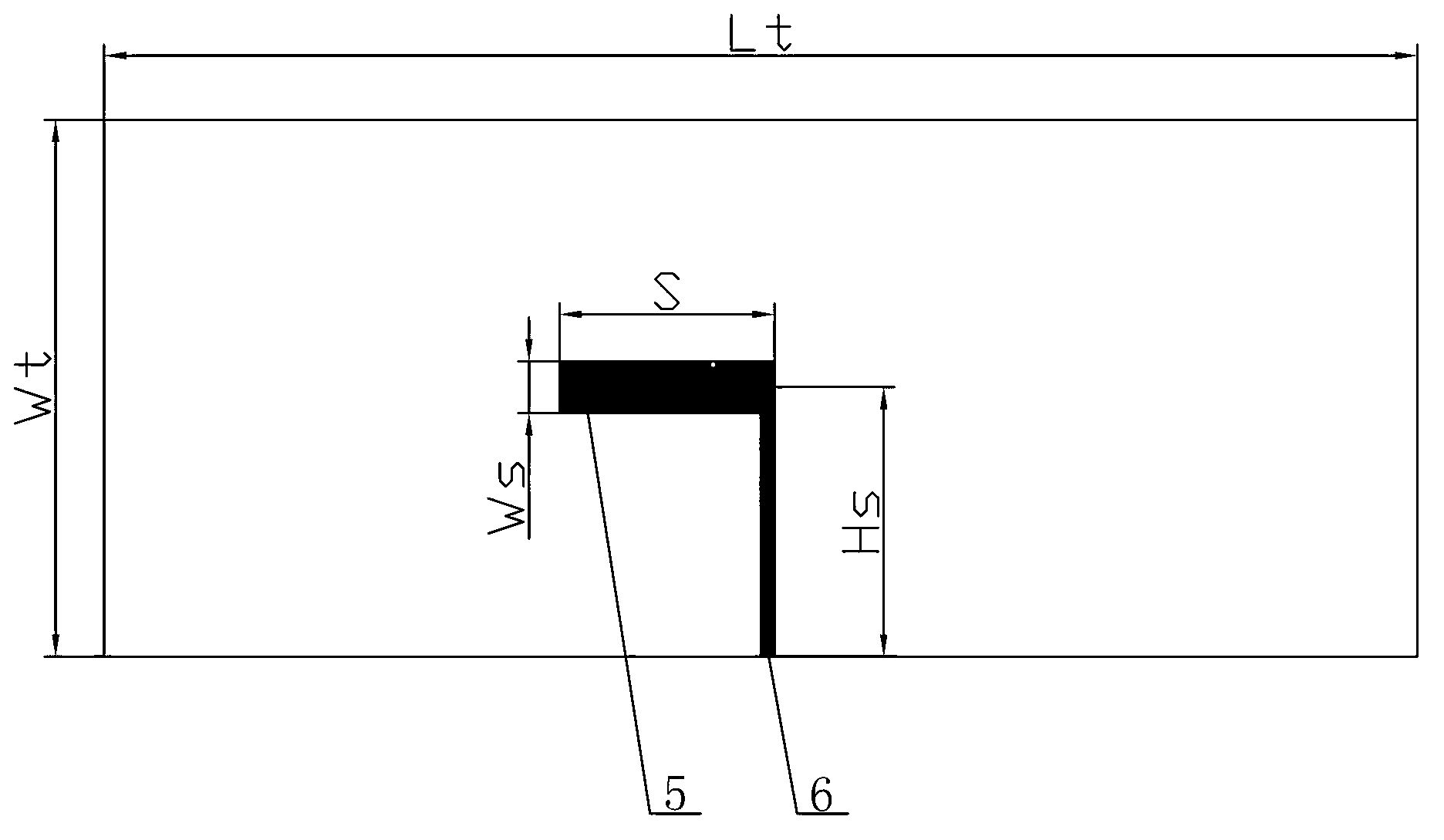

[0007] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, a printed-type Yagi antenna loaded with an oscillator in this embodiment and fed by a balanced microstrip line includes a dielectric board 7, and this embodiment also includes a director 1, a first symmetrical oscillator 2, a second symmetrical The vibrator 3, the reflector 4, the terminal feeder loading 5 and the feeding part 6, the director 1 and the reflector 4 are printed side by side on the front side of the dielectric plate 7 from top to bottom, and the first symmetrical vibrator 2 and the second symmetrical vibrator 3 is printed in a straight line between the director 1 and the reflector 4, the reflector 4 is connected to the feeding part 6 located in the middle of the lower edge of the dielectric plate 7, and the first symmetrical vibrator 2 is close to the side of the second symmetrical vibrator 3 The feeder is connected to the reflector 4 through the feeder, the termin...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 with figure 2 Describe this embodiment, the length Ld of the director 1 of the printed Yagi antenna of the dipole-loaded balanced microstrip line feeding described in this embodiment is 42mm, the width Wd of the director 1 is 5.8mm, the first The length L of the symmetrical oscillator 2 is 31 mm, the width W of the first symmetrical oscillator 2 is 6.4 mm, the structural size of the second symmetrical oscillator 3 is the same as that of the first symmetrical oscillator 2, the length Lr of the reflector 4 is 89.3 mm, and the reflector 4 The width Wr of the terminal feeder is 6.4mm, the length S of the terminal feeder load 5 is 16.5mm, the width Ws of the terminal feeder 5 is 4mm, the length Lt of the dielectric plate 7 is 100mm, and the width Wt of the dielectric plate 7 is 38.5mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 with figure 2 Describe this embodiment, the center distance Sd between the director 1 and the second symmetrical vibrator 3 of the printed Yagi antenna of the dipole-loaded balanced microstrip line feeding described in this embodiment is 5.8mm, and the second symmetrical The center distance Sr between the vibrator 3 and the reflector 4 is 8.7 mm, and the distance Hs between the center of the terminal feeder loading 5 and the lower edge of the dielectric plate 7 is 19.5 mm. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com