Optical-thermal-electric integrated power-generation module

A power generation module and photothermoelectric technology, which is applied in photovoltaic power generation, photoradiation generators, generators/motors, etc., can solve the problems of high production cost, shortage of silicon materials, low conversion efficiency, etc., improve utilization rate, and be easy to popularize The effect of low promotion and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

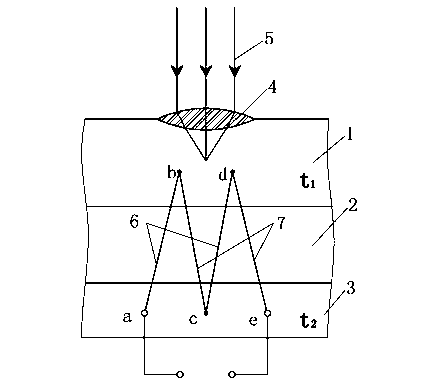

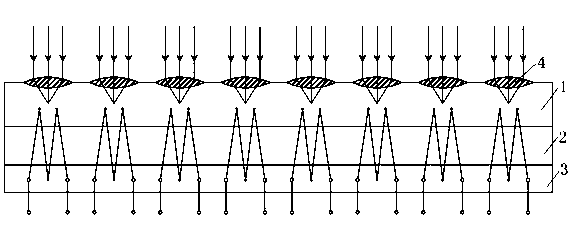

[0028] like figure 1 , 2 As shown, two kinds of metal wires with different electron number densities are arranged in the high temperature layer 1, heat insulation layer 2 and low temperature layer 3 below the convex lens 4, i.e. the first metal wire 6 and the second metal wire 7, the first metal wire 6 One end of a is placed in the low-temperature layer 3, and the other end is placed in the high-temperature layer 1. One end c of the second metal wire 7 is also placed in the low-temperature layer 3 , and the other end is connected to the first metal wire 6 at b and placed in the high-temperature layer 1 . In this way, the first metal wire 6 and the second metal wire 7 constitute the first group of thermocouples on the left side. In the same way, the first metal wire 6 and the second metal wire 7 constitute the second group of thermocouples on the right side. Two thermocouples are connected in series to form a thermopile; the two ends a and e of the thermopile will obtain tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com