Film forming device, film forming method, rotational frequency optimisation method, and storage medium

A technology of film forming device and starting position, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of no hint, ambiguity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

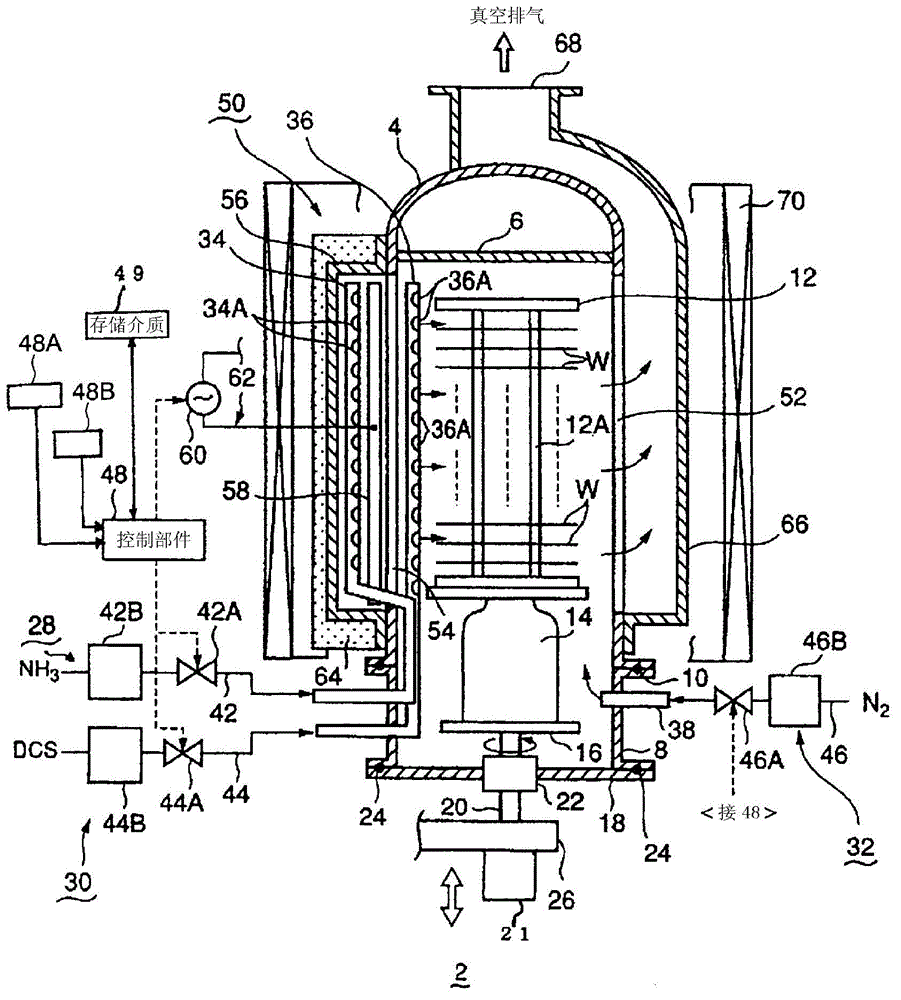

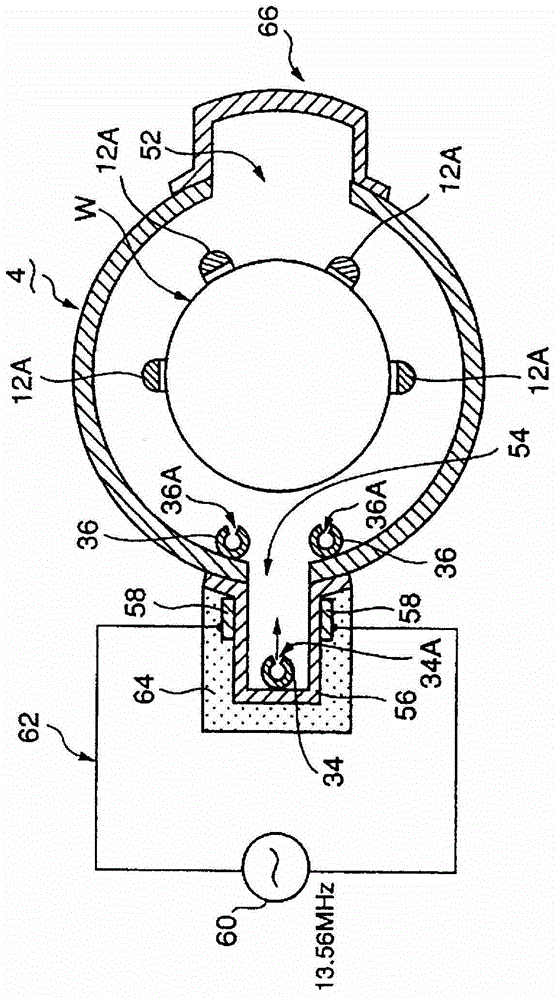

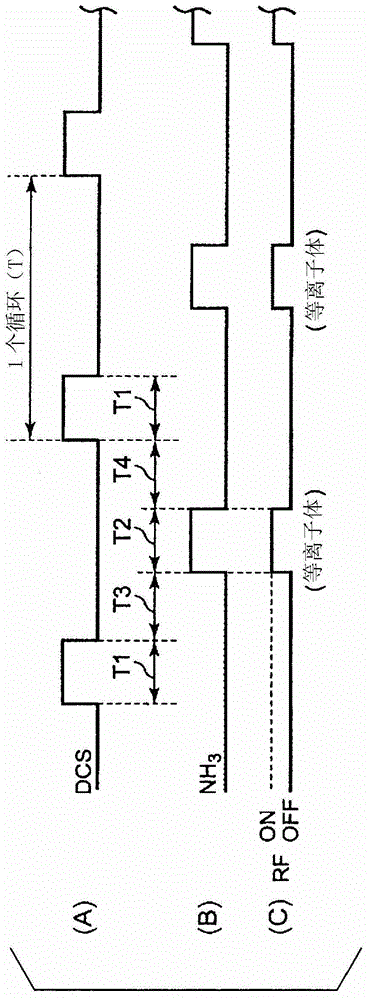

[0139] A case where ALD film formation is performed under the above-mentioned condition 2 for 30 cycles using the film formation apparatus 2 of the present invention will be described. First, the operating conditions of the device are input in advance. When data such as processing temperature, processing pressure, and gas flow rate contain the above-mentioned condition 2 and the division number K of the number that determines the supply start direction of the processing gas, as a processing recipe, the operator automatically connects to the processing of the control unit 48. The condition input section 48A inputs data. Alternatively, data may be transferred from a high-level host computer to the control unit 48 as a processing recipe. The control unit 48 is built in beforehand, and is used to determine the rotational speed satisfying the division number K specified by the program. Now, if the division number K specified by the process program is K=30, the control unit 48 is ...

no. 2 Embodiment

[0164] As a second example, when 30 cycles of ALD film formation are performed under the previous condition 2 using the film formation apparatus 2 of the present invention, ALD 1 is described by controlling the rotation speed at 1.9 rpm according to the specified operating conditions. cycle T to achieve the purpose of the invention in the same way as in the first embodiment.

[0165]First, as in the first embodiment, the operating conditions of the device are input in advance. In this case, the control unit 48 can change the ALD without changing the supply sequence, supply time, and supply amount of the reaction gas under the operating conditions specified in advance by adjusting, for example, the time for vacuuming and purging the inside of the processing container. The period T of 1 cycle. Assuming that the period of one cycle of ALD is T1, when K=30 and the rotation speed of the substrate is N=1.9 (rpm), T1 is determined by the control unit 48 through the following calcula...

no. 3 Embodiment

[0222] Using the above relationship, try to find the ALD cycle time Tx when K=160, the resolution of the motor used is Q=200, and N is a number rounded off from the decimal point in the timing chart of condition 2.

[0223] R=K / G=160 / 200=4 / 5

[0224] According to the above formula (9), 4·α=5·β

[0225] 5·β is 5 times the step angle of the motor, so 5×1.8°=9°

[0226] At this time, if 4·α is the new moving angle, the moving angle is 4×2.25°=9°

[0227] Therefore, as long as the moving angle is 9° again, the new division number K' is 360 / 9=40

[0228] According to the previous formula (3), (n±1 / 40)=(1 / 60)·2×Tx

[0229] In this case, Table 1 describes the relationship between n and Tx.

[0230] Table 1

[0231]

[0232] The cycle time of ALD can be shortened from 95sec to 90.75sec by adopting n=3, + Tx=90.75.

[0233] It is also possible to change the cycle time of ALD from 95 sec to 119.24 sec by adopting Tx=119.25 where n=4, -.

[0234] Confirm the result, according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com