Sliding frame arch breaking method of stock bin

A carriage and arch-breaking technology, which is applied in the field of silos, can solve the problems that arching sometimes exists and sometimes does not exist, the accuracy of arching judgment is not enough, and the force on one side of the carriage is unbalanced, etc., so that the position error is small, Simple method and structure, high loop efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

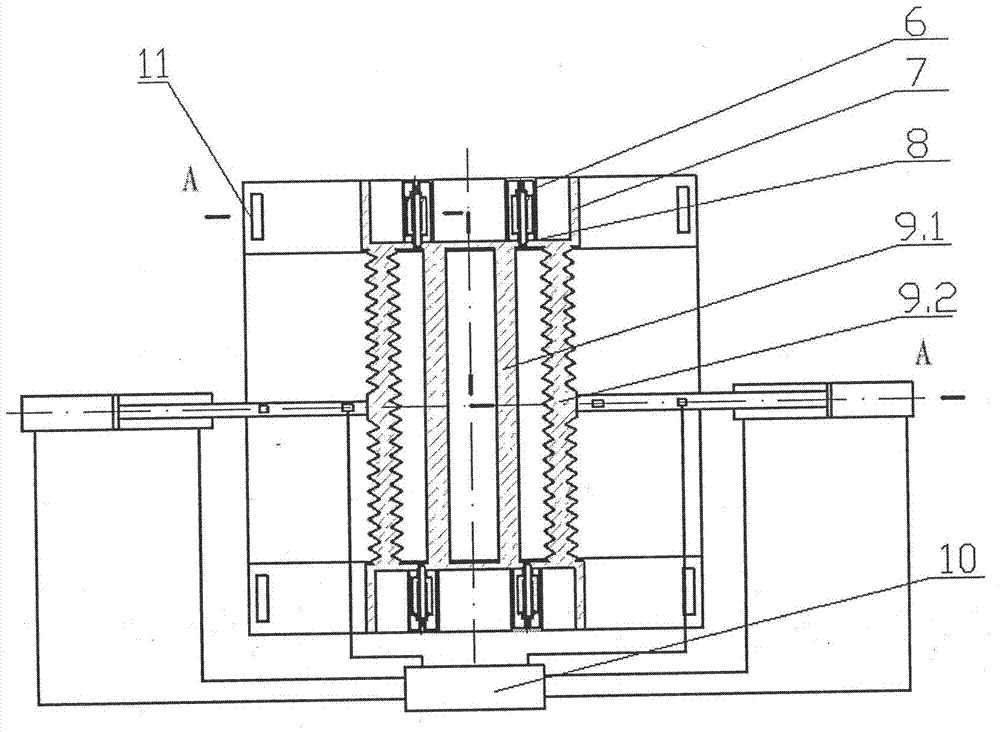

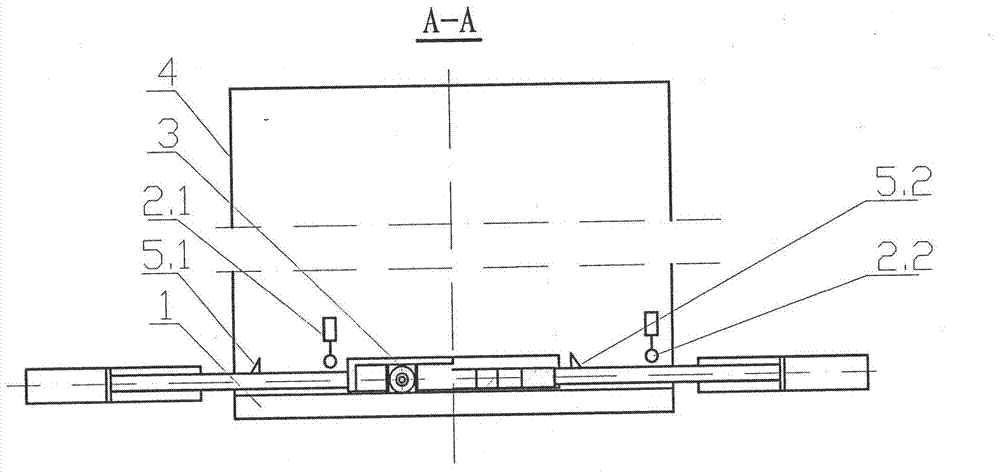

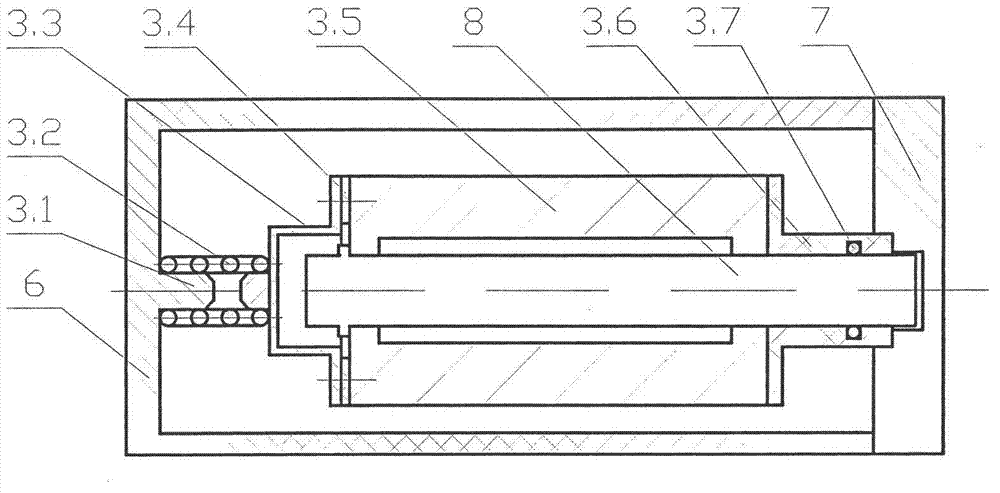

[0021] As shown in the figure, the method for breaking the arch of the silo carriage of the present invention is realized based on the arch breaking device of the silo carriage of the following structure, which includes a guide rail 1, a carriage, a power system 10 and a silo body 4, the described Guide rail 1 is arranged on both sides of the bottom of silo body 4, and described carriage is made up of carriage body 7 and carriage rod 9, is characterized in that: described guide rail 1 is provided with roller cover 6 and roller 3, so The roller cover 6 and the roller 3 are connected with the carriage at the same time, the roller 3 is placed in the roller cover 6, the carriage rod 9 includes an inner layer and an outer layer carriage rod and is distributed symmetrically along the center of the carriage, and the inner layer slides The frame bar 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com