Quaternary alloy sealing material

A technology of sealing materials and quaternary alloys, which is applied in the field of sealing materials, can solve problems such as unsatisfactory effects, insufficient airtightness of devices, poor oxidation resistance and corrosion resistance, etc., and achieve oxidation resistance and corrosion resistance Improvement, cleanliness, good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Put Ag, Cu, Ge and Co into the vacuum melting furnace according to the ratio, evacuate the furnace to 0.04Pa, and then heat to 1280°C;

[0015] (2) After Ag, Cu, Ge, and Co are completely melted in the vacuum melting furnace to form a melt, cool down to 1000°C, pour the melt into the shaping mold, and after the temperature drops to room temperature, remove the shaping mold from the vacuum Take it out from the smelting furnace to obtain the ingot required for processing the sealing material;

[0016] (3) Roll the ingot on a rolling mill. When the thickness reaches 1mm, roll it into a vacuum heat treatment furnace and heat it up to 650°C for 3 hours, then lower it to room temperature, take it out, and roll it to a thickness of 0.1mm. Just the desired shape.

Embodiment 2

[0018] (1) Put Ag, Cu, Ge and Co into the vacuum melting furnace according to the ratio, evacuate the furnace to 0.2Pa, and then heat to 1200°C;

[0019] (2) After Ag, Cu, Ge, and Co are completely melted in the vacuum melting furnace to form a melt, cool down to 1050°C, pour the melt into the shaping mold, and after the temperature drops to room temperature, remove the shaping mold from vacuum Take it out from the smelting furnace to obtain the ingot required for processing the sealing material;

[0020] (3) Roll the cast ingot on a rolling mill. When the thickness reaches 1.5mm, roll it into a vacuum heat treatment furnace and heat it up to 600°C for 2 hours, then lower it to room temperature, take it out, and roll it to a thickness of 0.04mm. into the desired shape.

Embodiment 3

[0022] (1) Put Ag, Cu, Ge and Co into the vacuum melting furnace according to the ratio, evacuate the furnace to 0.4Pa, and then heat to 1350°C;

[0023] (2) After Ag, Cu, Ge and Co are completely melted in the vacuum melting furnace to form a melt, cool down to 1100°C, pour the melt into the shaping mold, and after the temperature drops to room temperature, remove the shaping mold from vacuum Take it out from the smelting furnace to obtain the ingot required for processing the sealing material;

[0024] (3) Roll the ingot on a rolling mill. When the thickness reaches 2mm, roll it into a vacuum heat treatment furnace and heat it up to 700°C for 4 hours, then lower it to room temperature, take it out, and roll it to a thickness of 0.2mm. Just the desired shape.

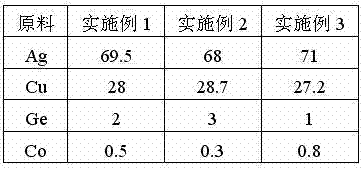

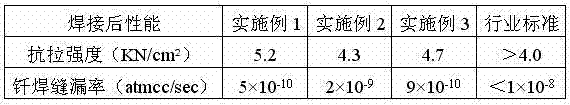

[0025] The mass of Ag, Cu, Ge, and Co used in Examples 1-3 is shown in Table 1, and the unit is kg.

[0026] Table 1

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com