Novel composite polyester felt and manufacturing method of novel composite polyester felt

A composite polyester, a new type of technology, applied in non-woven fabrics, textiles, papermaking, roads, etc., can solve problems such as road potholes, achieve the effects of prolonging service life, preventing rutting, and good breaking and tearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

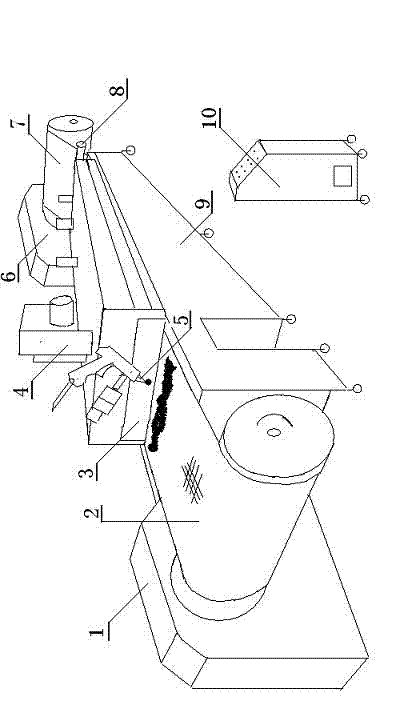

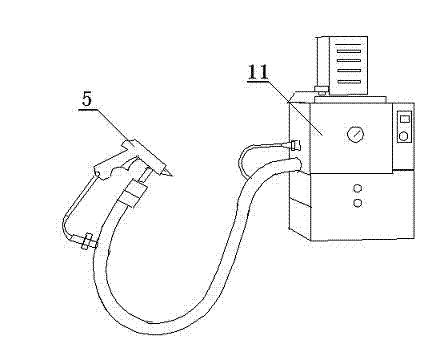

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0019] The present invention relates to a novel composite polyester felt. The main components of the novel composite polyester felt include non-alkali glass fiber, polyester fiber and other auxiliary fiber mixed fibers. The diameter of the non-alkali glass fiber is 11-14 μm. The length is 15~20mm; the diameter of the polyester fiber is 4~8μm; the auxiliary fiber accounts for about 5% of the mixed fiber; in the process of producing polyester felt, the final molding of the product is realized by an adhesive, and the adhesive It is a highly cohesive chemical mixed emulsion containing waterproof ingredients. The following ingredients are used: acrylic acid:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com