Micro-water transmitter

A transmitter and micro-water sensor technology, which is applied in the field of high-voltage equipment detection devices, can solve the problems of poor measurement timeliness and low reliability, and achieve the effect of solving poor measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

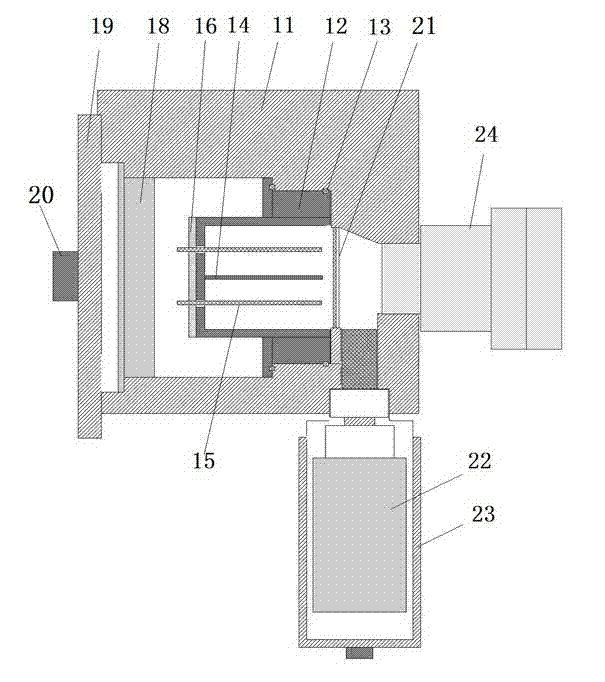

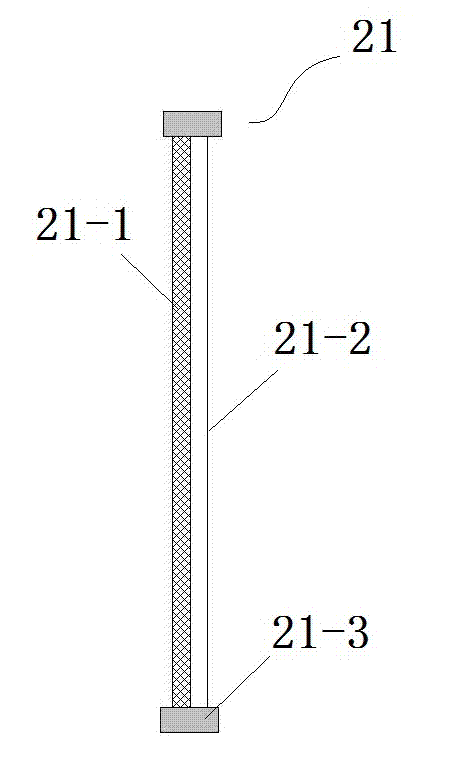

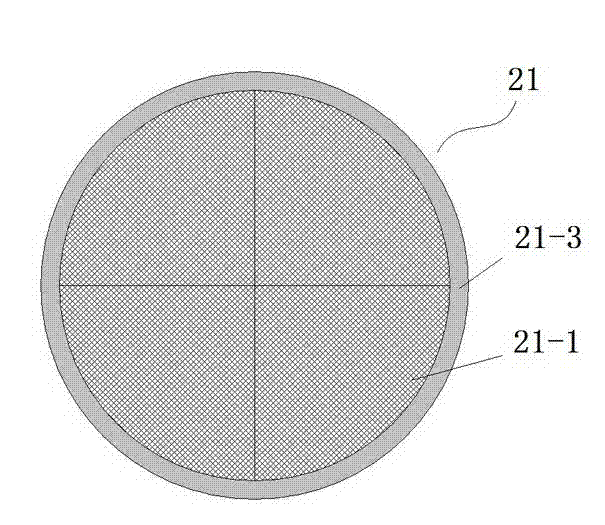

[0023] Embodiment 1 of the micro-water transmitter of the present invention, such as Figure 1-8 As shown, it includes a shell, which is a closed shell and includes a main body 11 at the front end. The main body 11 has an inner cavity. 12. In this embodiment, the sealing sleeve 12 adopts a copper-cast integrated structure, which is in the shape of a cylinder with an open front end and a sealed rear end. The front end of the sealing sleeve has a connecting part 12-1, and the connecting part The outer diameter of 12-1 is larger than the outer diameter of other parts of the sealing sleeve, and the rear end of the connecting part has an everted edge, and the sealing sleeve 12 passes through the large, The stepped surface between the small-diameter sections is flange-connected, so that the sealing sleeve 12 is fixedly assembled in the housing. In addition, the small-diameter section hole of the stepped hole formed by the connecting part of the sealing sleeve 12 and the inner cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com