Yogurt all-in-one machine for Kerir grain cultivation and fermentation and method for making yogurt

A kefir grain and integrated machine technology, applied in the field of food manufacturing, can solve the problems of cumbersome fermentation steps, long time period, and long time period, so as to achieve the effect of sufficient fermentation and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

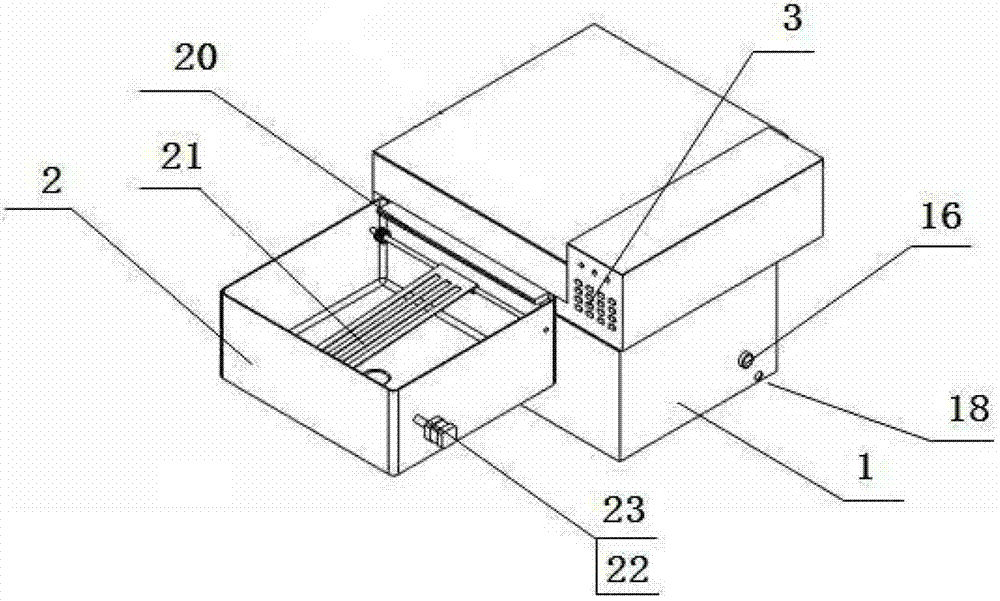

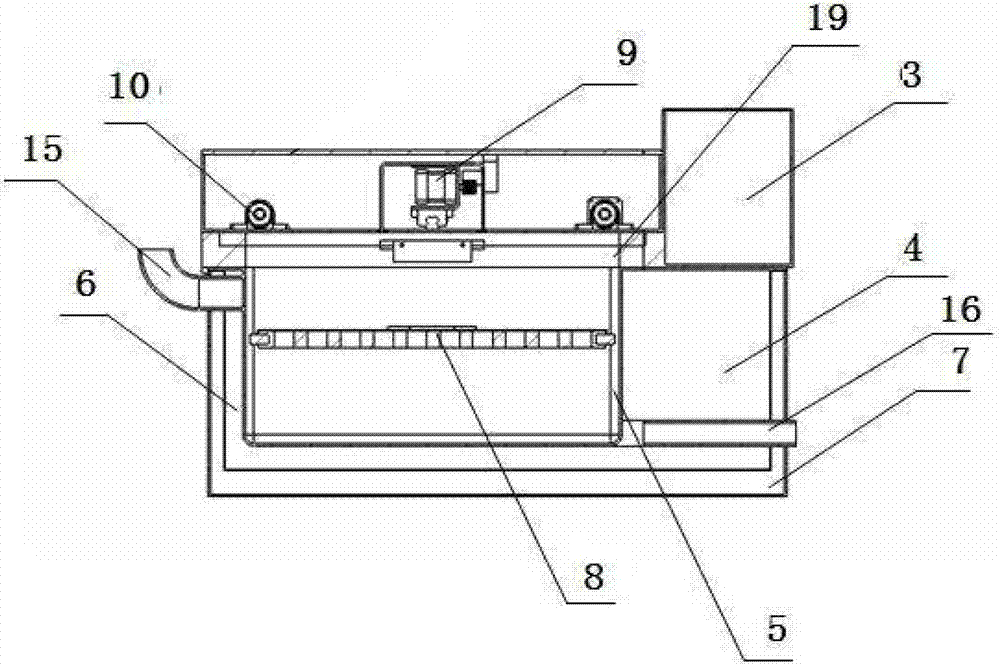

[0034] Such as figure 1 As shown, the present embodiment includes: an incubator 1, a drain tank 2 communicated with the incubator 1 and a control box 3 provided with a controller, wherein: the incubator 1 includes: a heating box 4, an inner bag 5, a water bath interval 6 and Insulation interval 7, wherein: the inside of the inner container 5 is provided with a kefir grain fixing table 8, the heating box 4 is located on one side of the outer wall of the inner container 5, and the other side of the outer wall of the inner container 5 is provided with a water bath interval 6, and the water bath interval 6 and the heating The outer periphery of box 4 is provided with insulation interval 7.

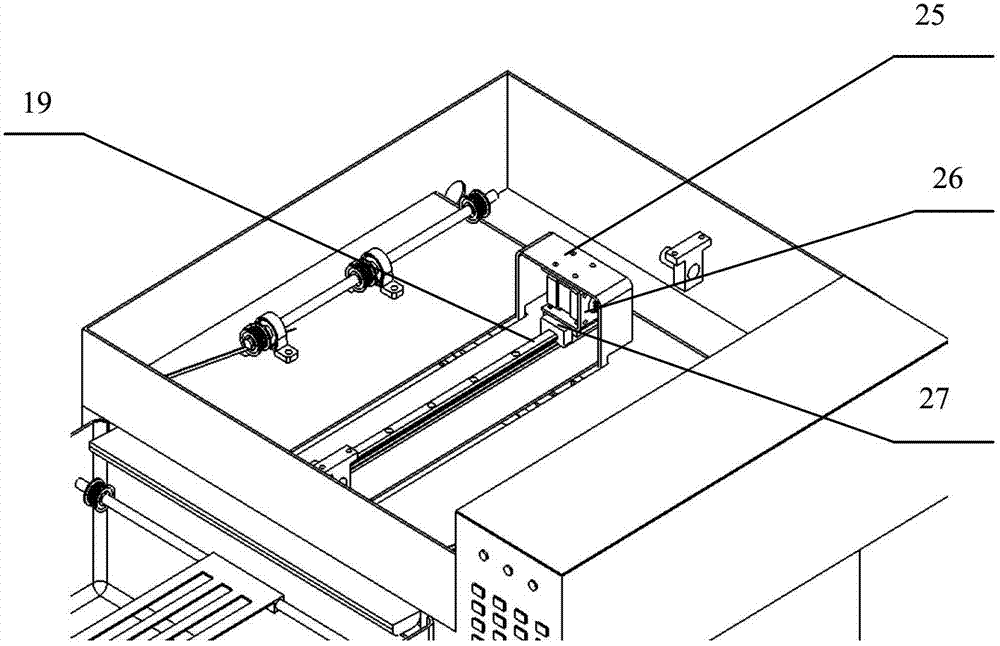

[0035] The top of the inner container 5 is provided with a pushing device 9 and a wire wheel 10, wherein: the wire wheel 10 is controlled by a controller, and the wire wheel 10 is connected with the kefir grain fixing table 8 by a connecting rope, and the pushing device 9 is located at The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap