Preparation method of negative electrode slurry for 3D printing

A negative electrode slurry, 3D printing technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of long research cycle, high mold opening cost, unfavorable new product development, etc. Qualification rate and performance, the effect of improving fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

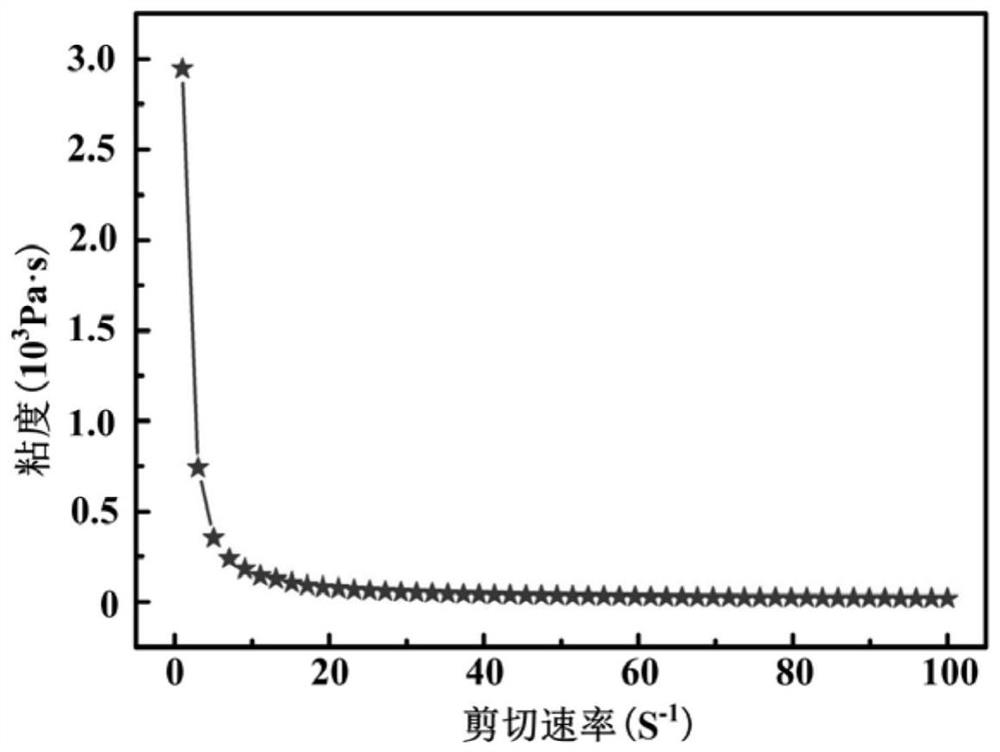

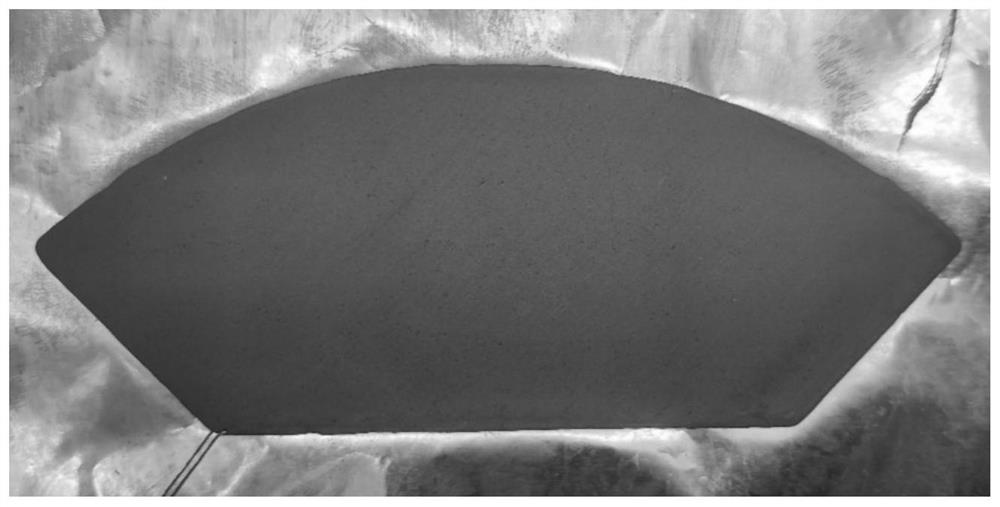

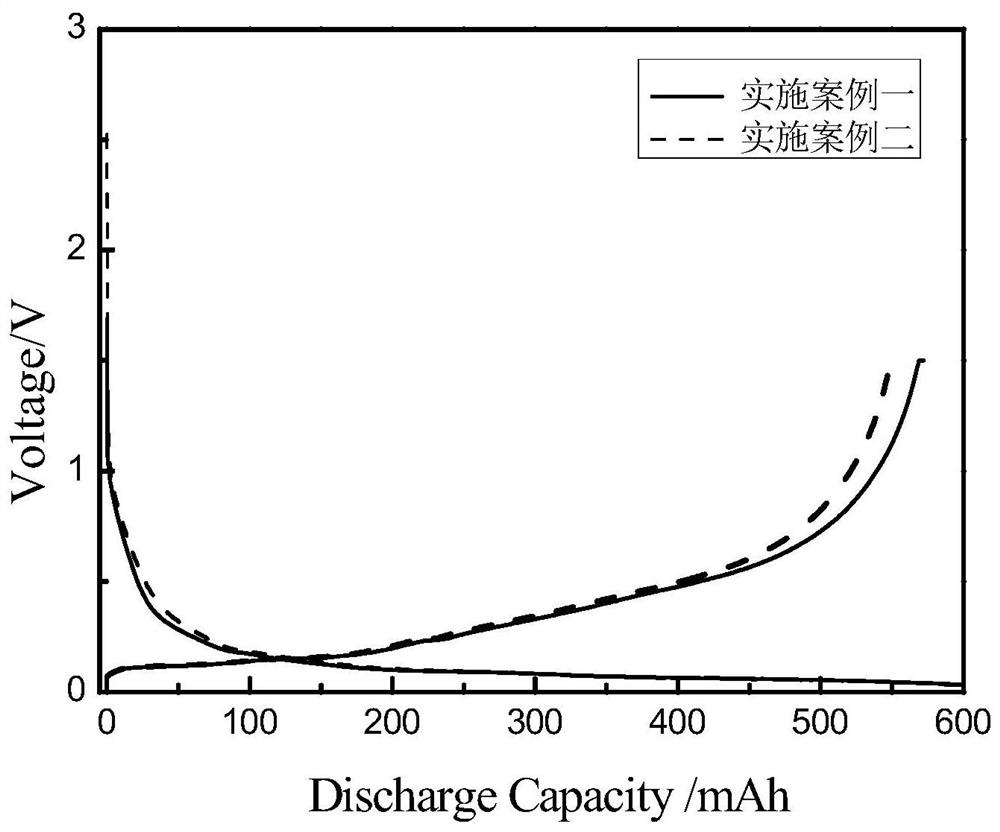

Embodiment 1

[0028] Weigh 2.5g sodium carboxymethylcellulose (CMC) into 100g deionized water, dissolve with ultrasonic vibration for 10min, and obtain solution A. Weigh 1.6g of superconducting carbon black and 1.6g of carbon nanotubes into solution A, and use a planetary disperser at 1200r / min for 2min, 1800r / min for 1min, and 1200r / min for 2min to obtain solution B. Weigh 50g of silicon carbon material into solution B, use a planetary disperser at 1200r / min for 2min, 1800r / min for 1min, and 1200r / min for 2min to obtain solution C; weigh 3.75g of styrene-butadiene rubber (SBR) into solution C , using a planetary disperser at 1200r / min for 2min, 1800r / min for 1min, 1200r / min for 2min, the viscosity of the slurry is 800-1500cps, and passed through a 200-mesh sieve to obtain 3D printed negative electrode slurry.

Embodiment 2

[0030] Weigh 1.7 g of sodium carboxymethylcellulose (CMC) and add it into 100 g of deionized water, and dissolve it by ultrasonic vibration for 8 min to obtain solution A. Weigh 0.6g of superconducting carbon black and 0.8g of carbon nanotubes into solution A, and use a planetary disperser at 1200r / min for 1min, 1800r / min for 1min, and 1200r / min for 1min to obtain solution B. Weigh 50g of silicon carbon material into solution B, use a planetary disperser at 400r / min for 5min, 800r / min for 20min, 1800r / min for 2min, 800r / min for 20min, and 400r / min for 5min to obtain solution C; Take 2.5g of styrene-butadiene rubber (SBR) and add it to solution C, use a planetary disperser to turn it at 800r / min for 15min, turn it at 1800r / min for 2min, and turn it at 800r / min for 15min, the viscosity of the slurry is 500-1200cps, pass through a 150-mesh sieve, and get 3D printed negative electrode paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com