Novel dehumidifying apparatus on basis of hydrophilic/hydrophobic composite microporous membranes under microgravity

A composite membrane and microgravity technology, which is applied to devices for controlling the living conditions of space vehicles, membrane technology, semi-permeable membrane separation, etc., can solve the problems of consuming large electric power, not suitable for large and long-term use, and unable to recycle condensed water. , to achieve the effect of reducing weight and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

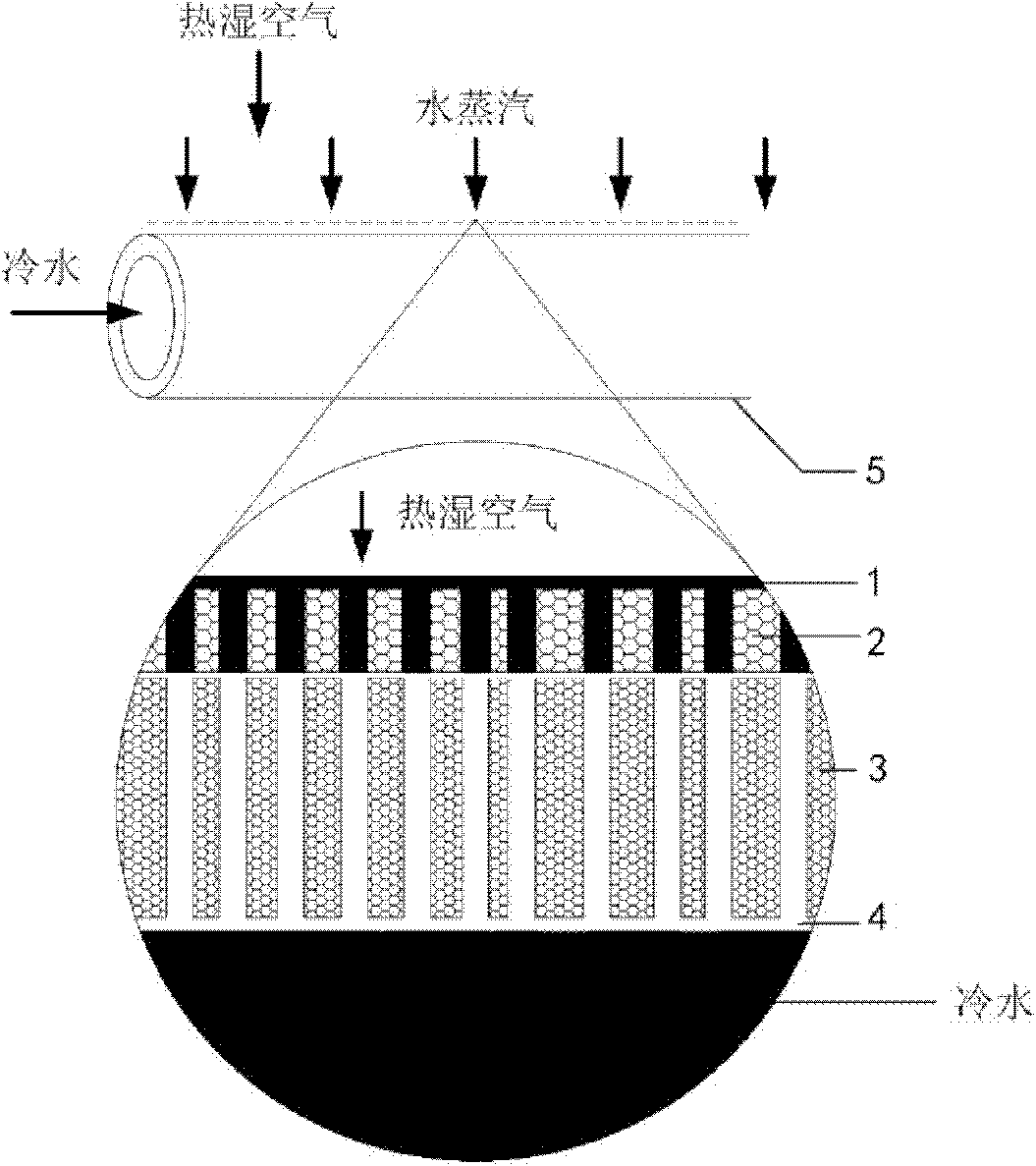

[0014] figure 1 It is a cross-sectional view of a hydrophilic / hydrophobic composite microporous membrane tube 5 according to an embodiment of the present invention. The wall of the hollow membrane tube in the dehumidifier is a hydrophilic / hydrophobic composite microporous membrane structure, and the inner wall of the composite membrane tube is a hydrophobic membrane layer 3, so that the cold water in the tube cannot penetrate to the outside of the tube under normal or low pressure; and The outer wall of the membrane tube is a hydrophilic membrane layer 2, which effectively ensures that the water vapor smoothly enters the micropores in the membrane after condensing on its surface, and the one-way transmission from the outer wall of the membrane tube to the inner wall of the membrane tube.

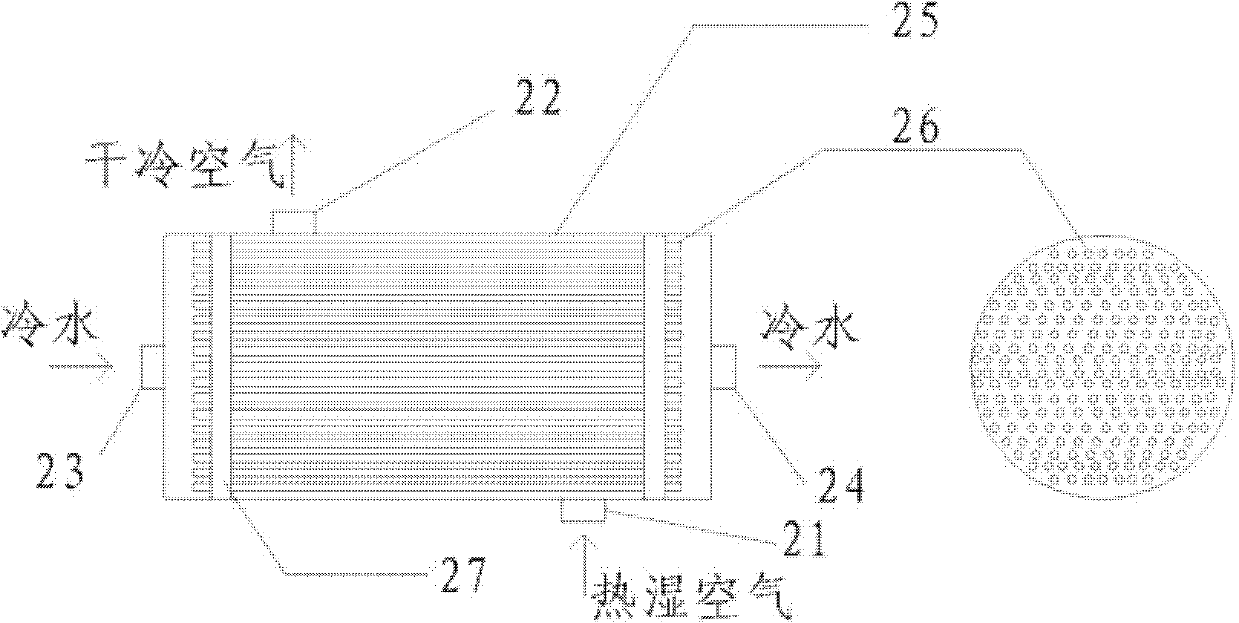

[0015] like figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com