Full hydraulic drive differential horizontal screw centrifuge

A decanter centrifuge, full hydraulic technology, applied in the centrifuge and other directions, can solve the problems of hydraulic oil leakage, small output torque hydraulic joint, large differential speed between the drum and the pusher, etc., and achieve high reliability and extended Long service life, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0017] In the structure of the existing differential decanter centrifuge, the present invention makes further improvements to its driving form. Adjust the rotation differential speed between the drum and the screw pusher to further reduce their differential speed to solve the problem that the material stays in the drum for a short time in the prior art and cause the content of the solid phase material after discharge. The water volume is higher and the wear rate of the auger is accelerated due to the excessive differential speed.

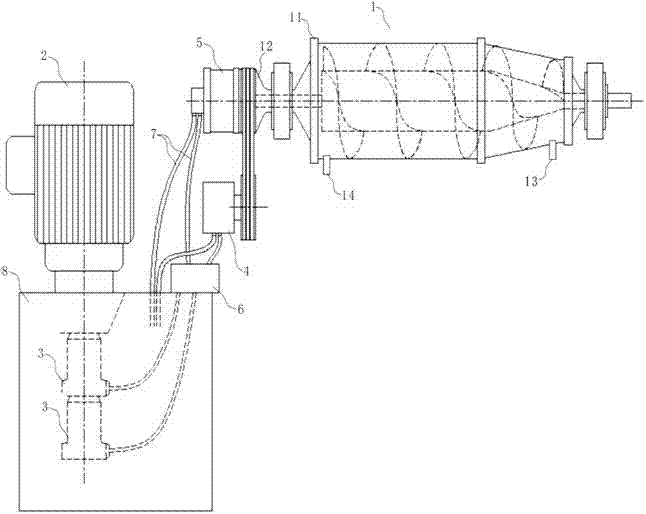

[0018] In view of the above technical problems, figure 1 shows a schematic structural diagram of the present invention, refer to figure 1 As shown, the first embodiment of the present invention is a fully hydraulically driven differential decanter centrifuge, which includes a decanter centrifuge body 1, a drive motor 2 and two hydraulic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com