One-time integral paint spraying method for paint coating of wind power blade and paint spraying special tool

A paint coating and wind power blade technology, applied in the field of paint spraying, can solve the problems of uneven paint thickness, waste of materials and labor, and many quality problems, so as to solve the problem of beautiful appearance, ensure product quality, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained by enumerating a specific embodiment below in conjunction with the accompanying drawings.

[0032] The present invention relates to a one-time overall spraying method of wind power blade paint coating, the specific embodiment is as follows, including the following steps:

[0033] Step 1: Preparation before spraying

[0034] Including paint preparation, sprayer, spray gun preparation, special tooling preparation for painting.

[0035] In step 1, the paint is evenly stirred and placed in the designated place for use; the air pressure range of the spray gun is 100-140bar.

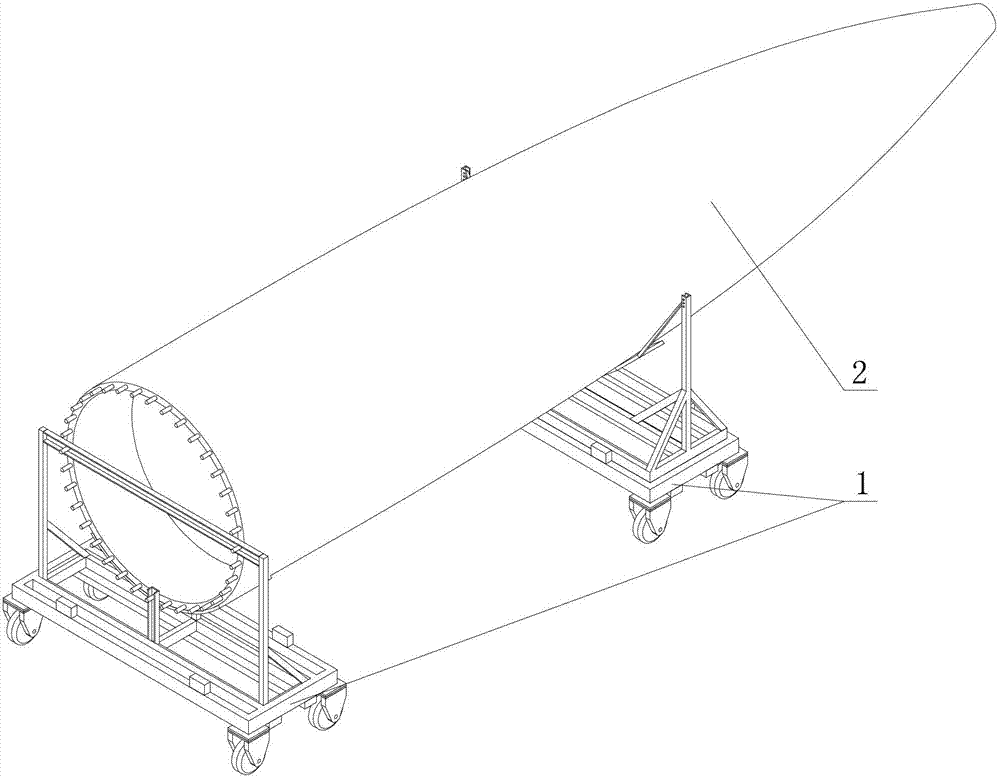

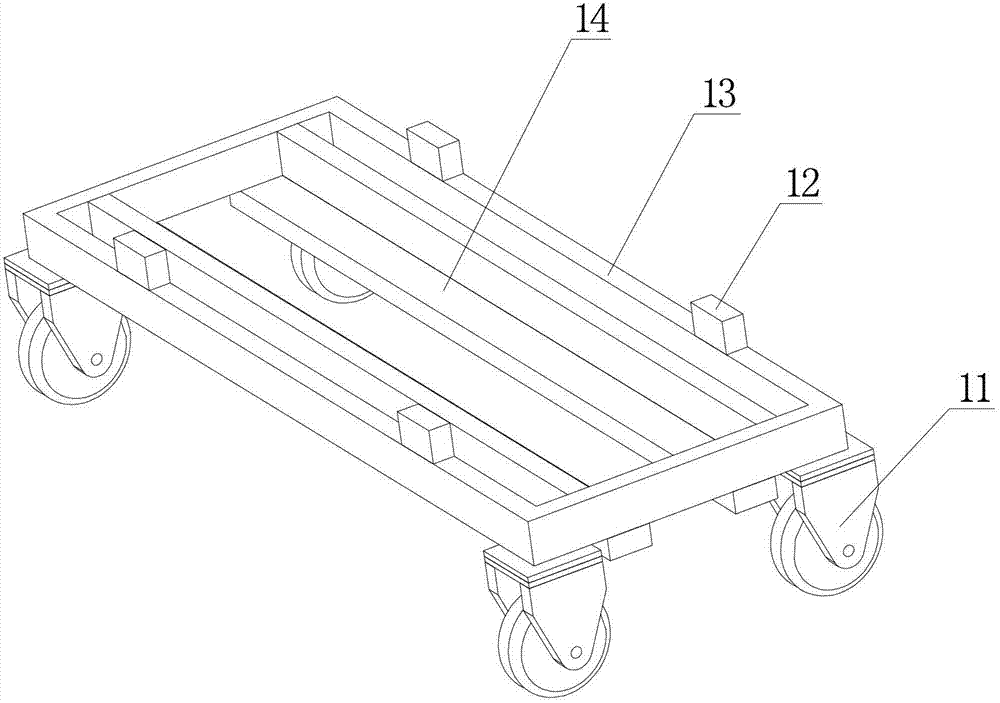

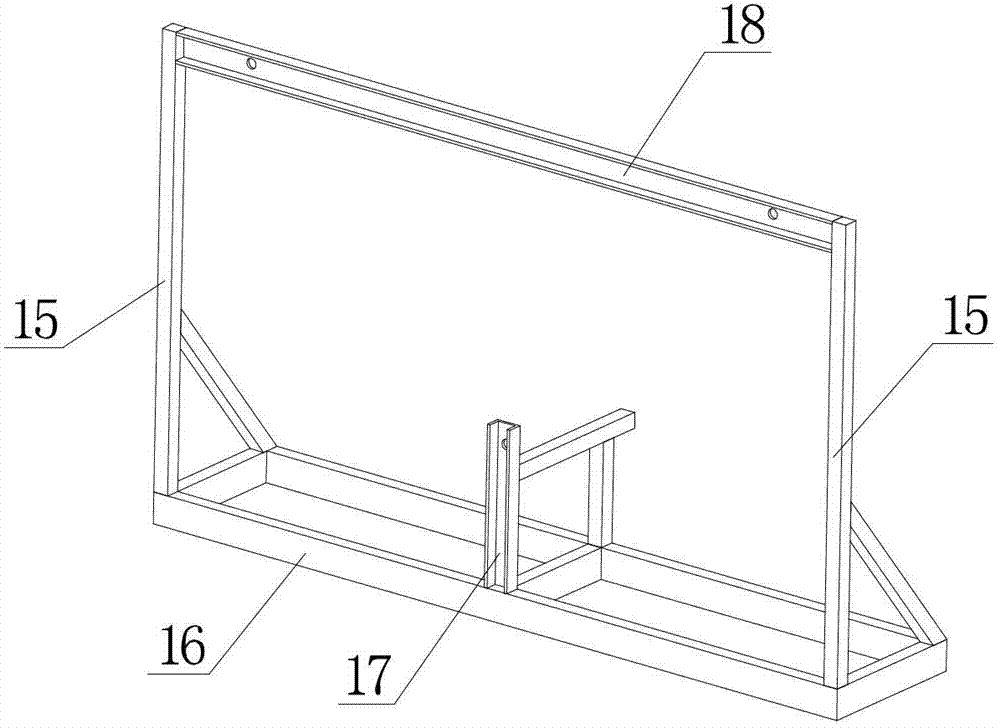

[0036] Such as Figure 1-Figure 4 As shown, the special tooling for painting is a left-right symmetrical structure, including a special trolley and a support; the special trolley includes wheels 11 and a vehicle body, and the upper end of the vehicle body is provided with a horizontal support surface; the support includes a support base 16 and a support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com