Manufacture method for fork of forklift

A manufacturing method and fork technology, applied in the field of forklift fork manufacturing, can solve problems such as not really solving safety problems, not being able to realize compensation, and high labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

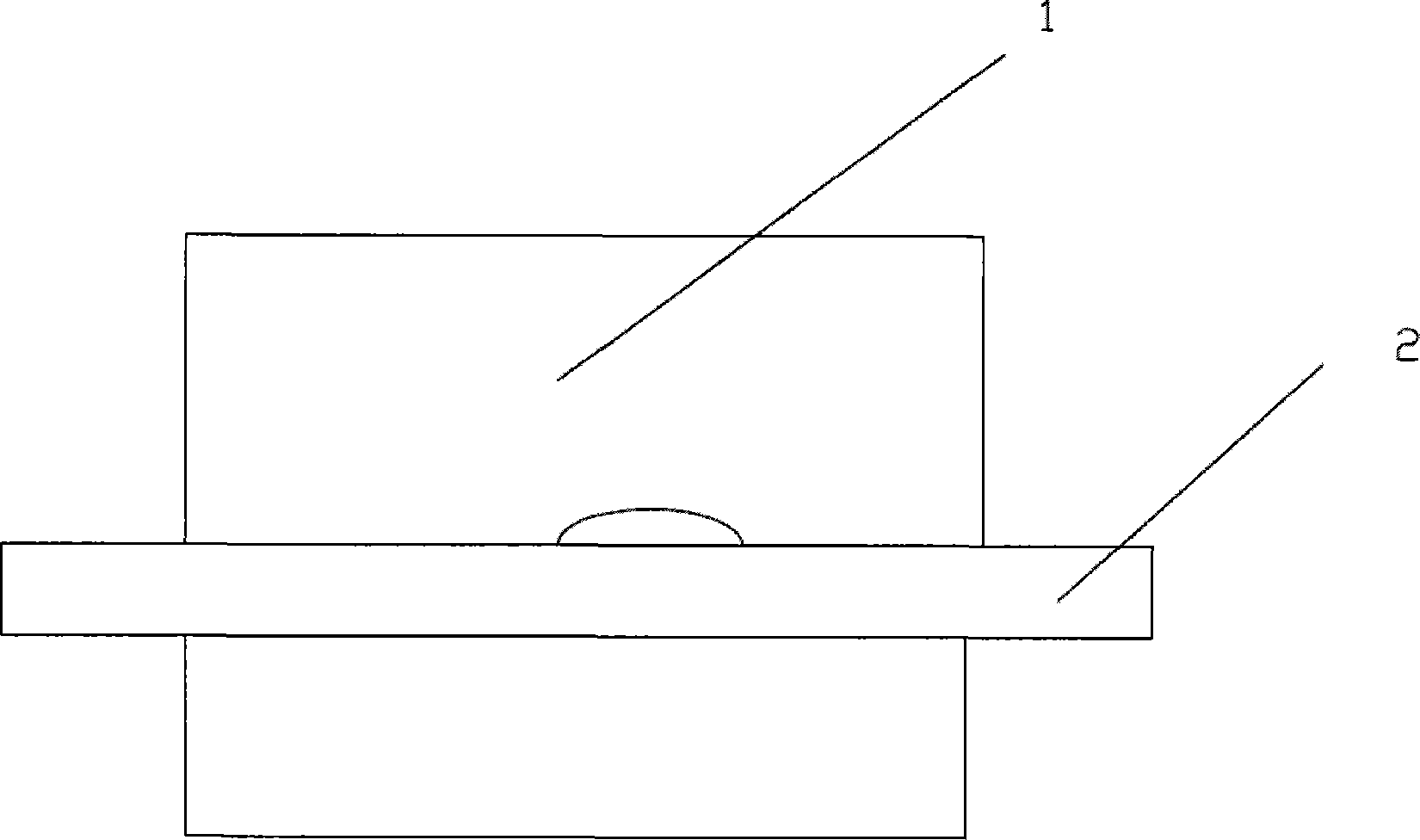

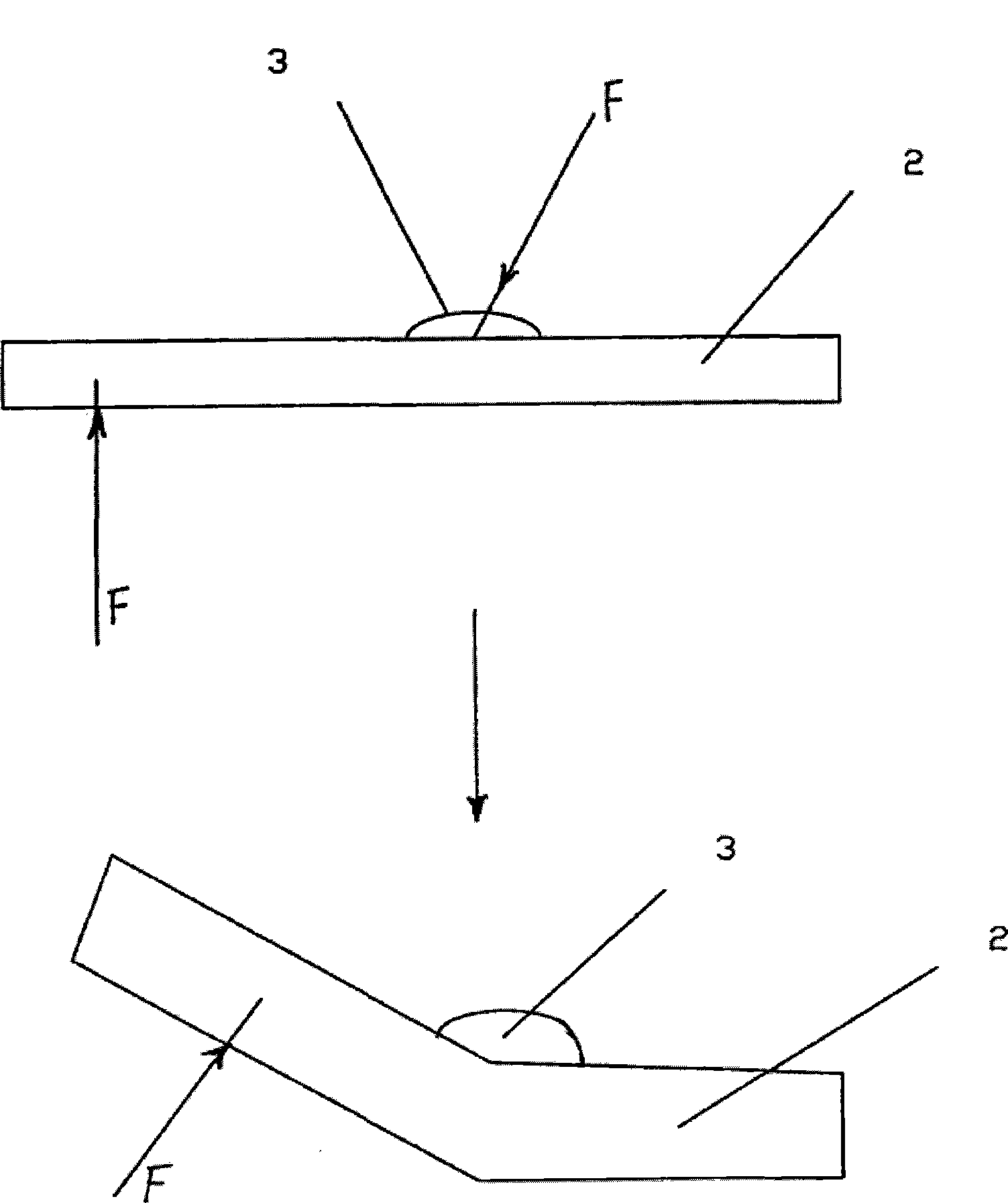

[0022] The following is attached Figure 1 to Figure 4 , to describe embodiments of the present invention in detail, examples of which are shown in the drawings, wherein the same or similar reference numerals represent the same or similar components or components having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary, and are only for explaining this patent, and cannot be construed as limiting this patent.

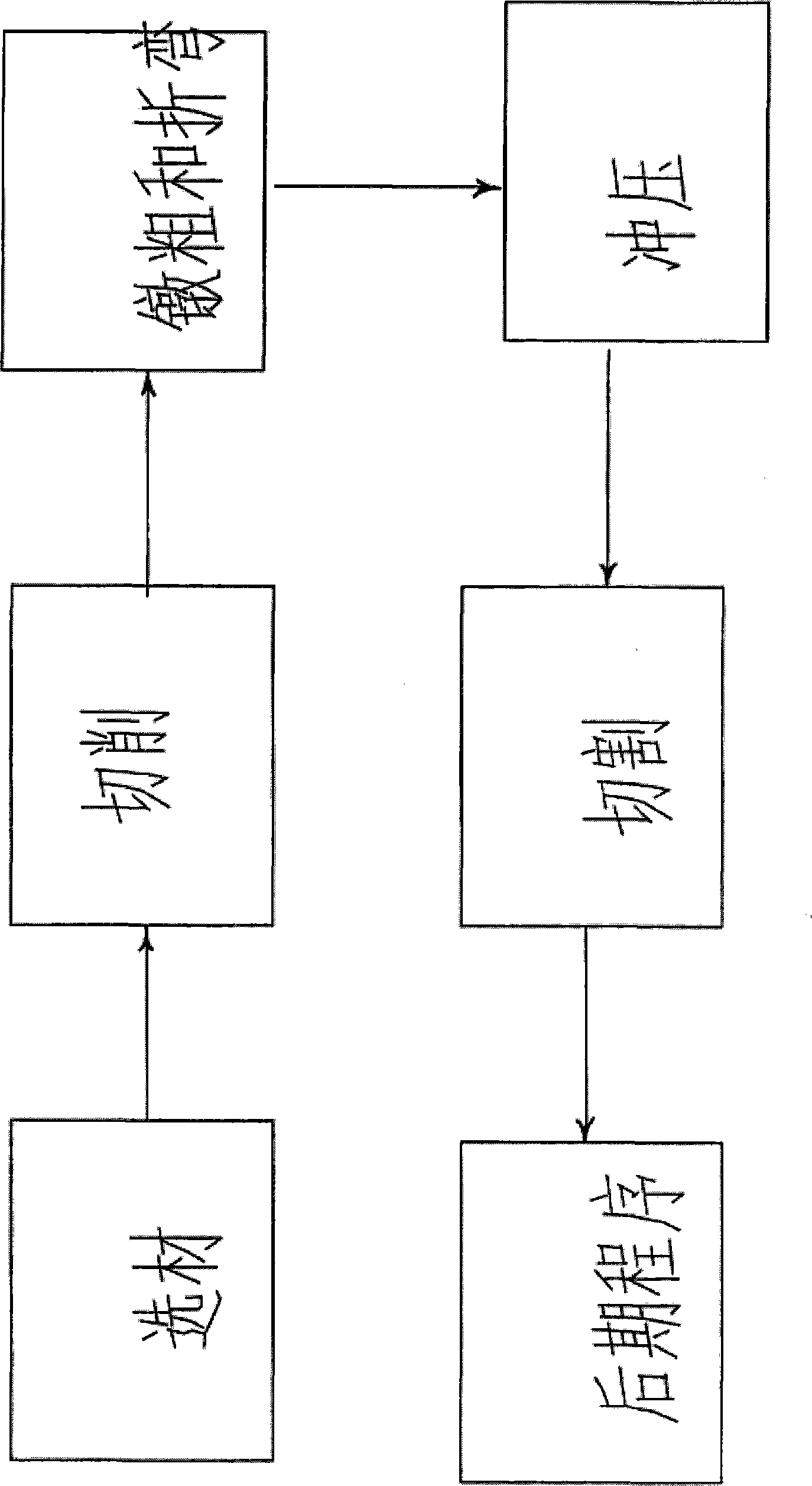

[0023] Forklift pallet fork manufacturing method of the present invention is as follows, see figure 1 :

[0024] A. Select a rectangular or square strip steel with the same section as the fork to be processed;

[0025] B. Cut off the long strip steel according to the length required by the process, and cut out the required slopes;

[0026] C, the cut profile 2 is locally heated at the bending place, and locally upset into a convex shape in the mold 1, and using the residual heat, it is bent into a fork ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com