Heat-shrinkable thin film and preparation method thereof

A film and heat shrinkable technology, applied in the field of heat shrinkable film and its preparation, can solve the problems of imperfect metallization effect, affecting the display of metallization effect, extinction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

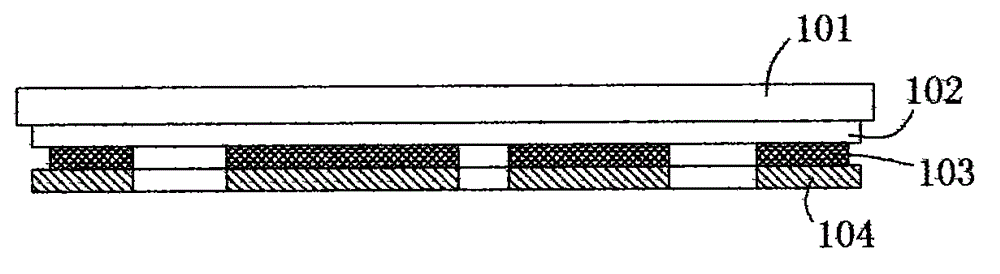

[0025] refer to figure 1 , the first embodiment of the present invention is a heat-shrinkable film, its film structure from outside to inside is a substrate layer 101, a printing layer 102, a local composite glue layer 103, and a local non-shrinkable aluminized film layer 104; wherein , the local composite glue layer 103 and the local non-shrinkable aluminized film layer 104 are set synchronously, the synchronous setting means that the size and shape are the same or the periphery of the non-shrinkable aluminized film is about 2 mm larger, and the positions are relative; the base material layer 101 is heat Shrink plastic film. The partial aluminum-plated layer is arranged at the position where the metallic color is required. In this embodiment, the printing layer is hollowed out at the position where the metallic color is required. In this embodiment, the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com