Automatic wall surface mortar painting machine

A coating machine and mortar technology, applied in the direction of construction and building structure, can solve the problems of delamination between the surface and the wall, poor quality, falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

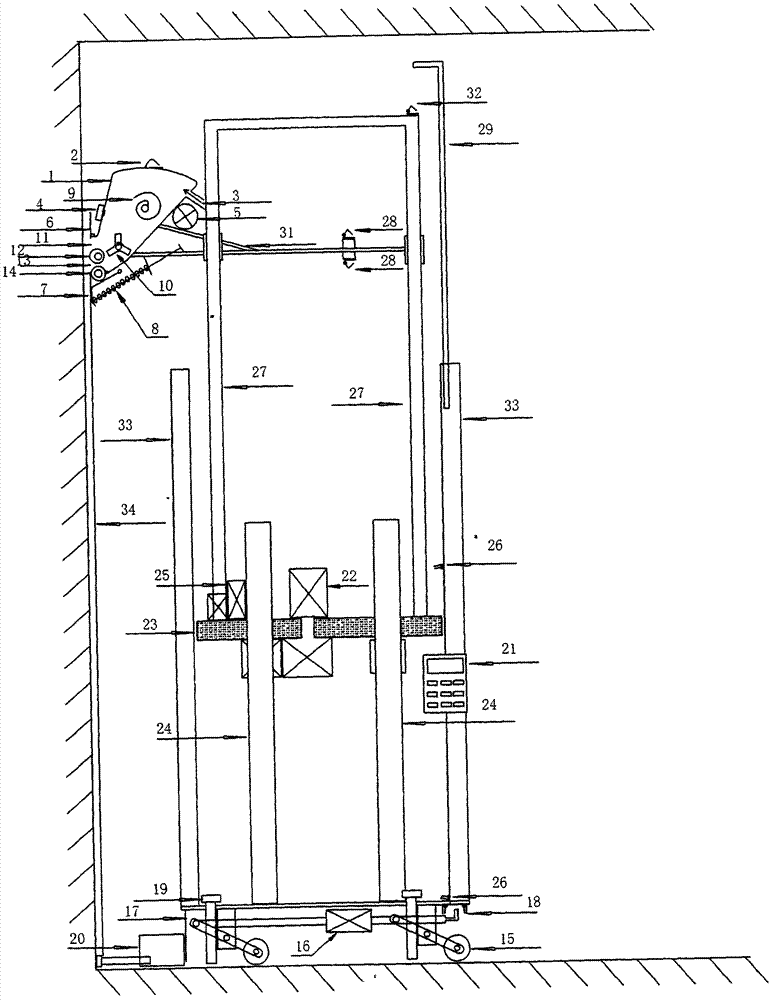

[0014] The automatic wall mortar applicator is moved to the stop bar 20 position, the electric control operation panel 21 is opened, and the automatic wall mortar applicator is allowed to work automatically. When the mortar applicator is down, move the automatic wall mortar applicator to the next working position. Repeatedly, until the end.

[0015] The working process and specific implementation of the present invention have been described above in conjunction with the accompanying drawings. Obviously, the present invention is not limited thereto, and various modifications within the scope of the present invention do not exceed the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com