Mining automatic atomizing and dust falling device

A spray dust-reducing and automatic technology, applied in valve devices, safety devices, valve operation/release devices, etc., can solve the problems of large investment, unsatisfactory equipment operation, complex equipment, etc., achieving low cost, good atomization effect, The effect of good dust suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

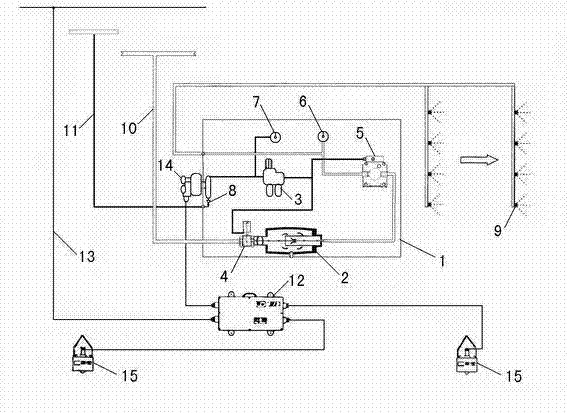

[0017] Such as figure 1 As shown, two sensors 15 are respectively arranged at the two ends of the dust suppression equipment, and the sensors 15 can adopt thermoluminescent control sensors. The sensors 15 are electrically connected to the host 12, and transmit electrical signals to the host. On the one hand, the electric ball valve 14 is electrically connected, and the relay in the host can transmit a signal to control the electric ball valve in the main control box to stop / start spraying; the electric ball valve 14 controls the air source processor 3, and the air source processor 3 is connected to the pneumatic control through the air pipe. 4 and booster pump 5, the air source processor 3 is connected to the air source through the air pressure pipe 11, and the air supply pressure can generally be selected to be ≥0.2 MPa; the air pressure pipe 11 is controlled by the electric ball valve 14 and the emergency switch 8; the emergency switch 8 can be Manual switch; on the one hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com