Sampling device used in satellite total leak rate testing leak detector

A sampling device and a technology of total leak rate, applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of cumbersome, difficult to automate, unstable flow of flow limiting device, etc., easy to control the size, reduce unnecessary The effect of certainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

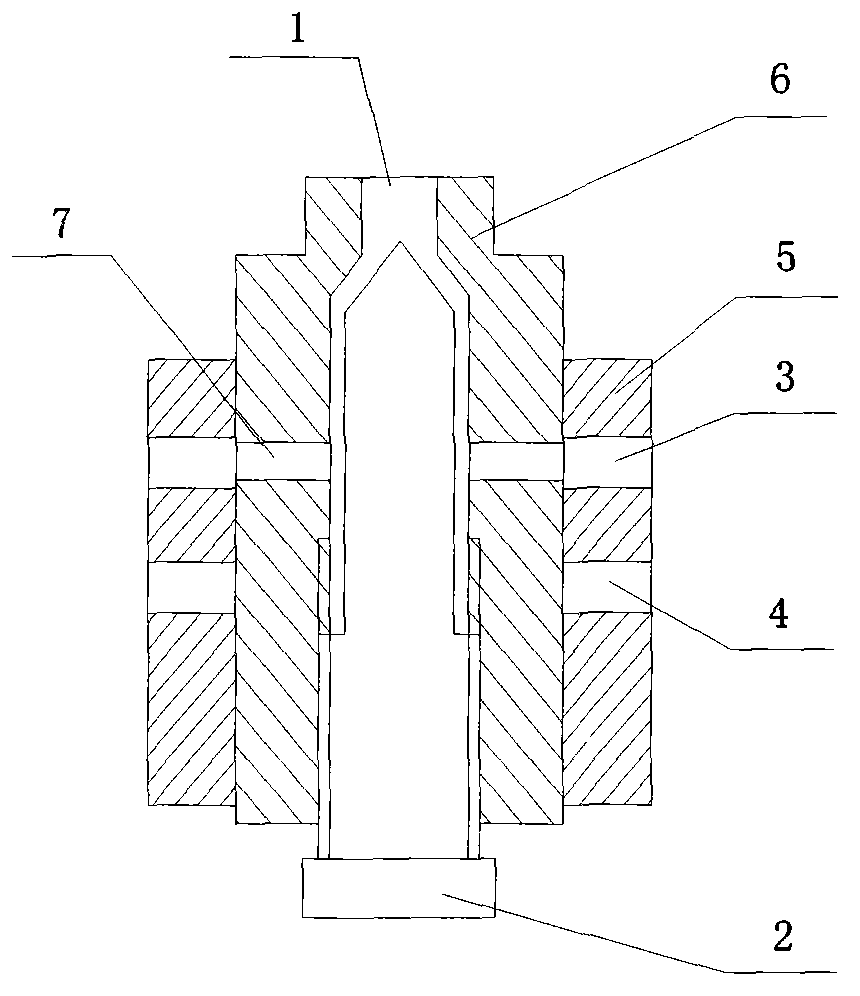

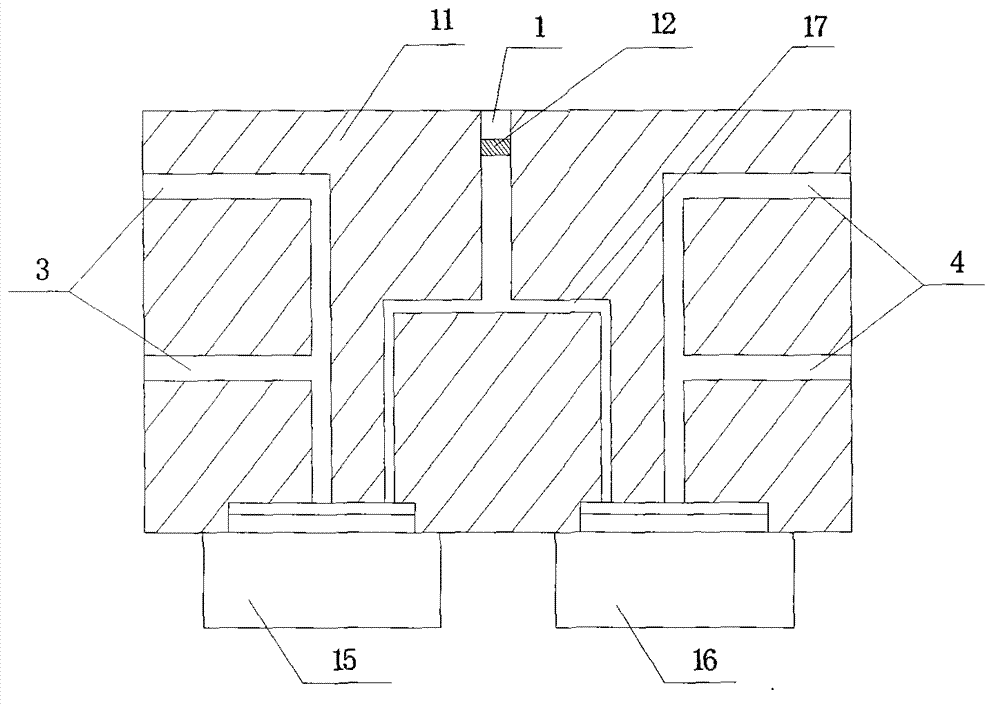

[0018] The present invention is used for the structural schematic diagram of the sampling device of satellite total leak rate test leak detector as figure 2 As shown, it includes a valve body 11, a small hole 12 of fixed size, a standard gas solenoid valve 15 and a sample gas solenoid valve 16. A leak detection port part 1 is arranged in the middle of the valve body, and the leak detection part 1 consists of the upper main channel and the The lower part consists of two sampling port channels, the upper part of the main channel is connected to the leak detection port of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com