Blind zone detection method in process of controlling pH value of desulfurization system

A technology for desulfurization system and process control, applied in various fluid ratio control, ratio control, separation methods, etc., to achieve the effect of improving detection efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

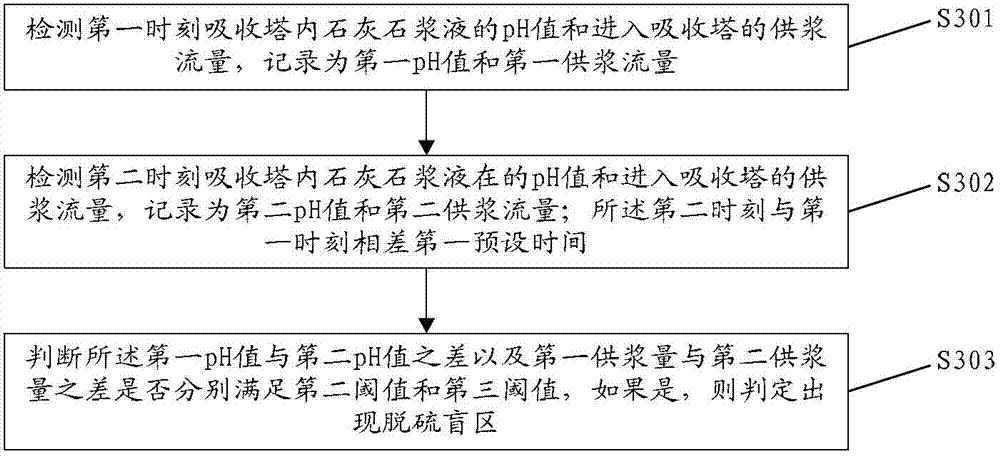

[0046] As mentioned above, in the pH value control process of the above-mentioned desulfurization system, there may be a desulfurization dead zone, which may cause a series of adverse effects. In order to avoid adverse consequences caused by the appearance of a desulfurization blind zone, the embodiment of the present application provides a method for detecting a blind zone during the pH value control process of a desulfurization system. see image 3 , which shows the flow of the blind spot detection method according to the first embodiment of the present application. This first embodiment includes:

[0047] Step S301: Detect the pH value of the limestone slurry in the absorption tower and the slurry supply flow rate entering the absorption tower at the first moment, and record as the first pH value and the first slurry supply flow rate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com