Manufacturing method of CAN bus branch batch production and after-sale restructuring method

A CAN bus, mass production technology, applied in the production field of CAN bus branch mass production, can solve the problems of time-consuming and labor-intensive reliability, cumbersome procedures, and material consumption, and achieve the effect of ensuring stability, simplifying production procedures, and saving operating hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

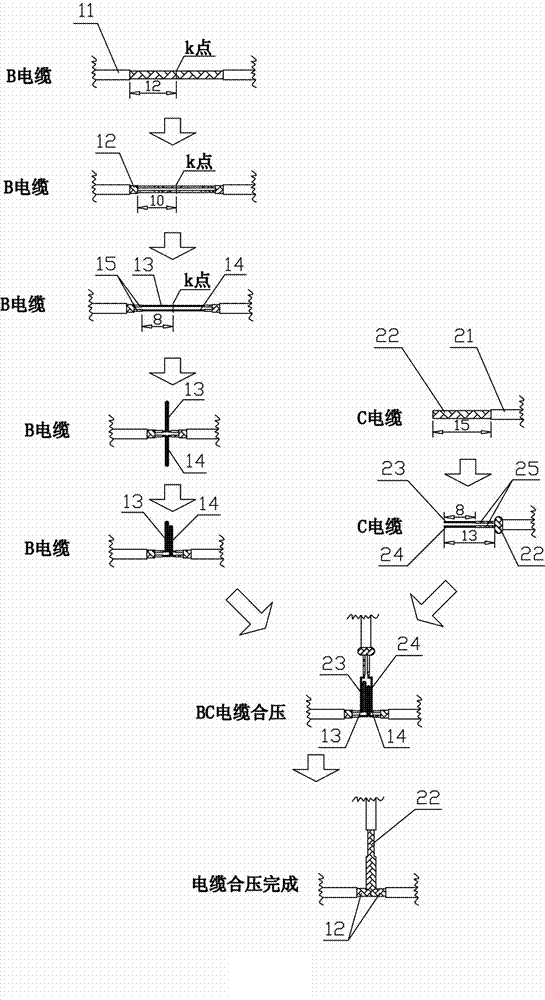

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details. Known components, methods and processes will not be described in detail below.

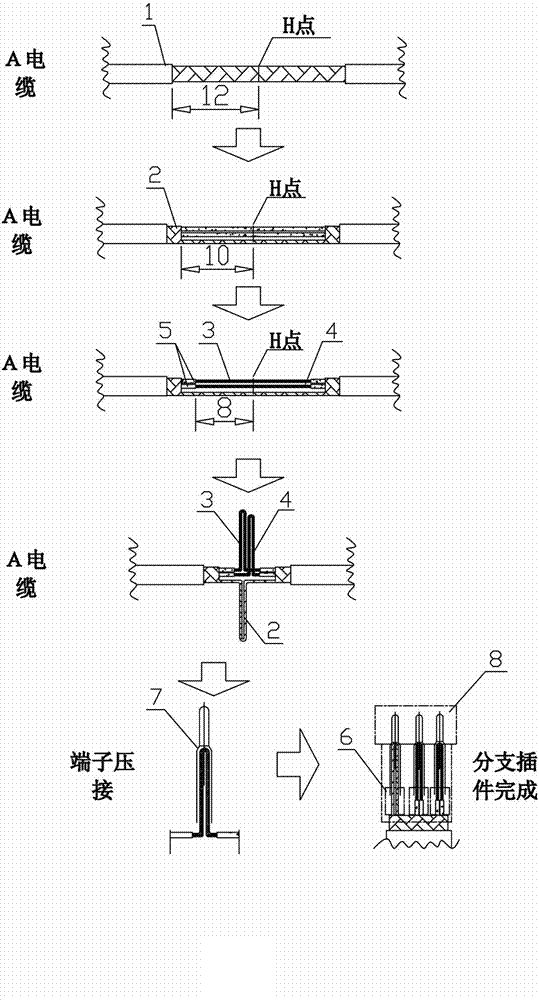

[0024] A kind of CAN bus branch production method, when for mass production situation, such as figure 1 As shown, it specifically includes the following steps:

[0025] a) Assume that the CAN bus main line is the A cable;

[0026] b) Select the branch connection position on the cable A in advance and mark H, take the cable with a length of about 12mm from the point H as the midpoint to both ends of the cable, and remove the insulation jacket 1 of the cable with a length of 24mm;

[0027] c) Take the H point as the midpoint and take a 10mm long cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com