A direct light-emitting micro-display array device and its preparation method

A light-emitting, micro-display technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems that have not yet been applied in the field of industrial production, poor insulation performance of buffer layer, and easy fracture of climbing metal, so as to improve stability And the reliability of the device, the reduction of steps, and the effect of reducing electrode crowding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

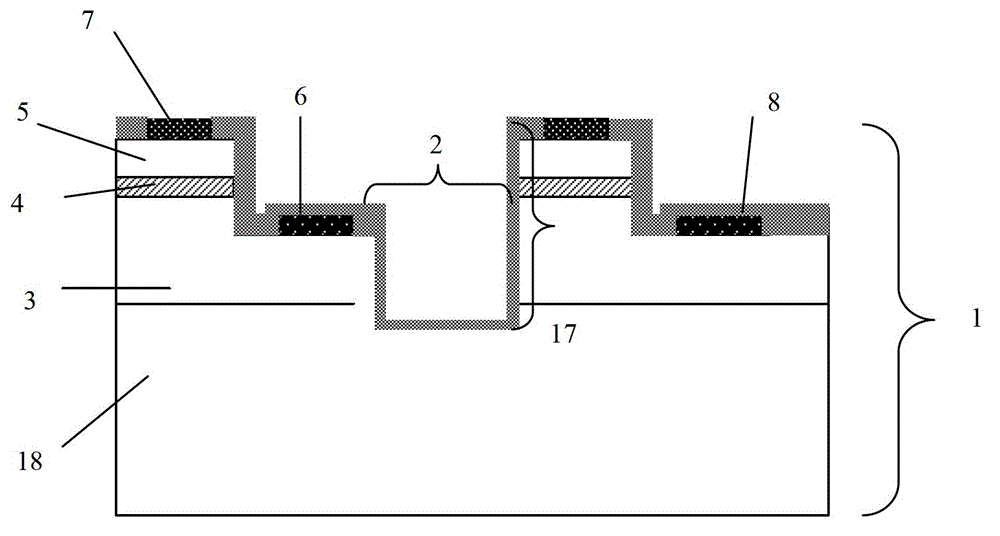

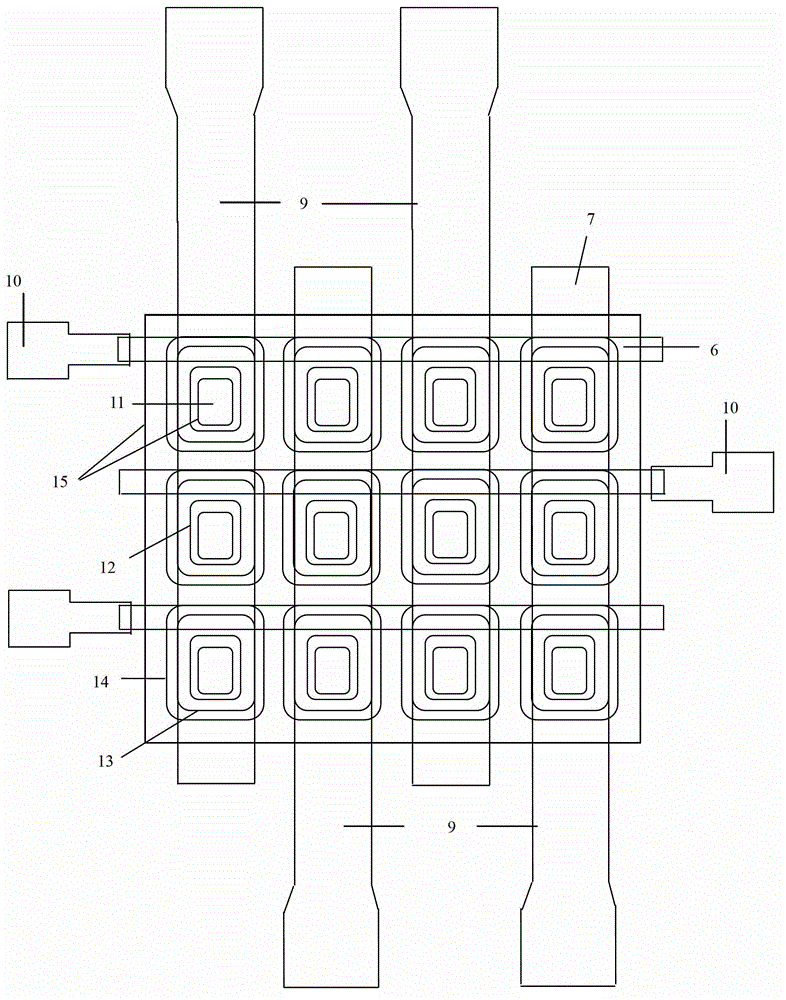

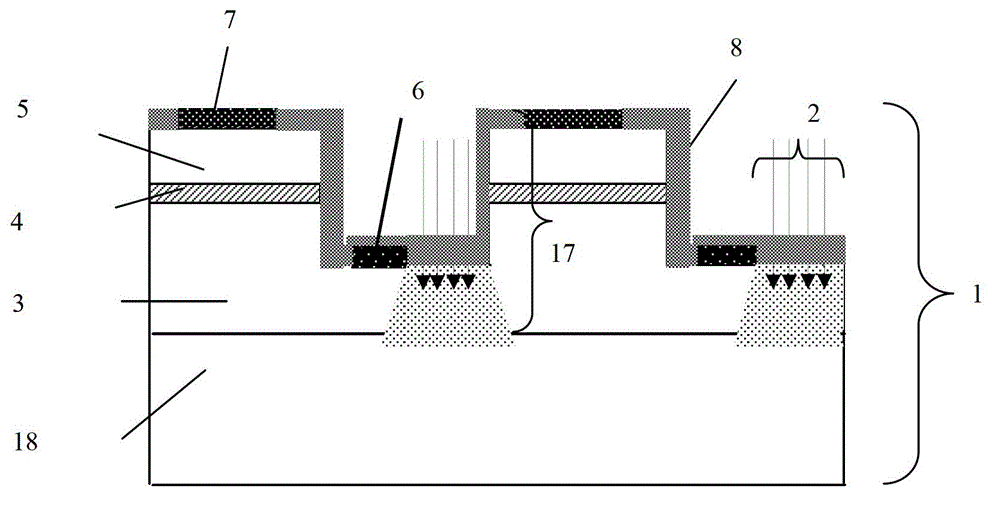

[0033] The direct light-emitting display array of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0034] Such as Figures 3 to 5 As shown, a direct light-emitting microdisplay array of the present invention is characterized in that it includes an epitaxial wafer 1, a semiconductor matrix unit 17, a semiconductor matrix isolation region 2, an n-type conductive layer 3, a light-emitting layer 4, a p-type conductive layer 5, n Electrode 6, p-electrode 7, isolation protection layer 8, anode line 9, cathode line 10; dry etching method is adopted on the epitaxial wafer 1, and the etching part reaches the n-type conductive layer 3 to form a plurality of semiconductor matrix units 17, Ions are implanted on the n-type conductive layer 3 exposed by etching until the substrate is formed to form a high-resistance region, and a semiconductor matrix isolation region 2 is obtained. n-electrodes 6 are arranged on the n-type conductive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com