LED packaged structure and surface roughening method for same

A technology of LED packaging and LED packaging body, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as process difficulties, silica gel adhesion, and difficulty in production, and achieve the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

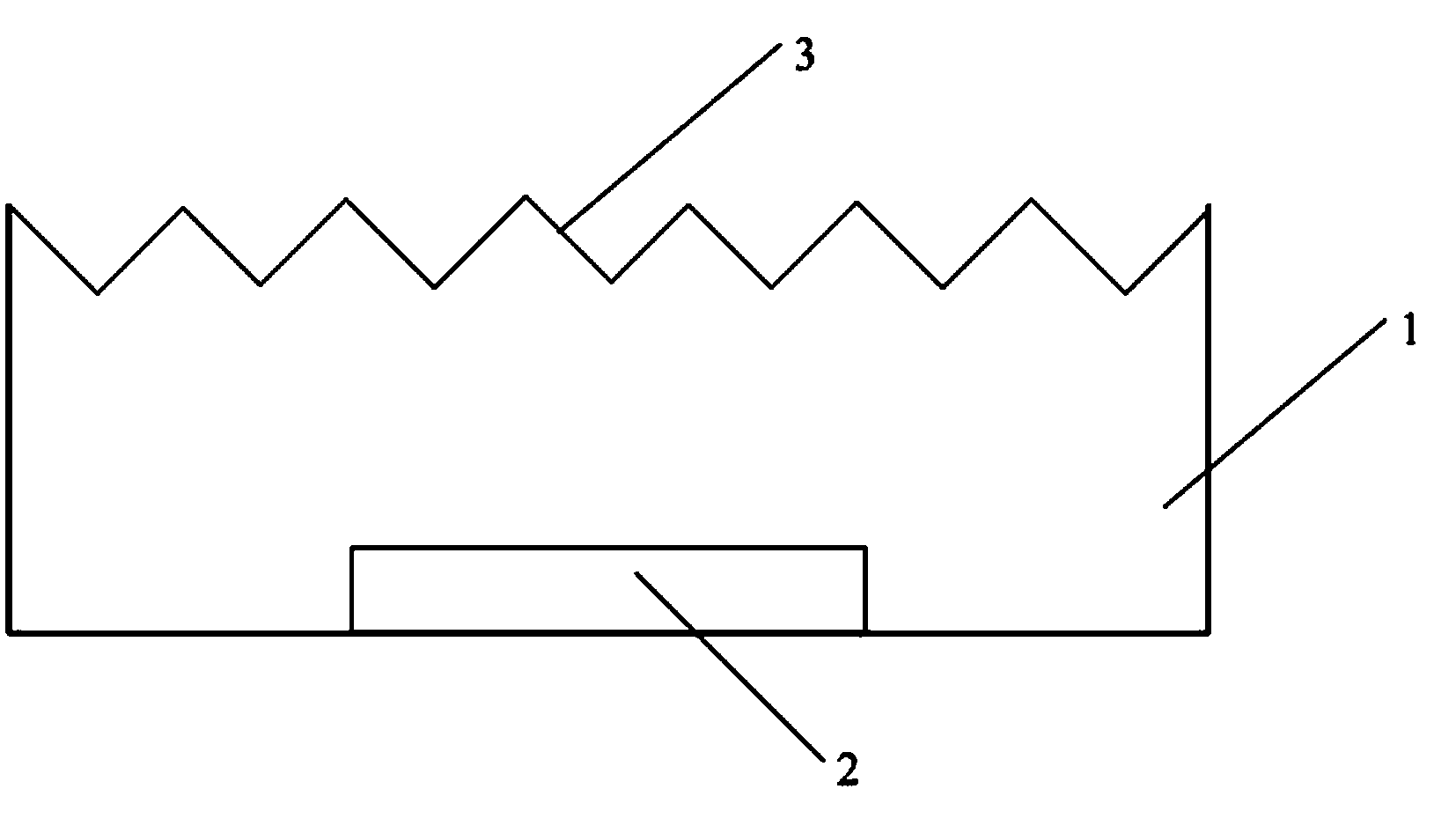

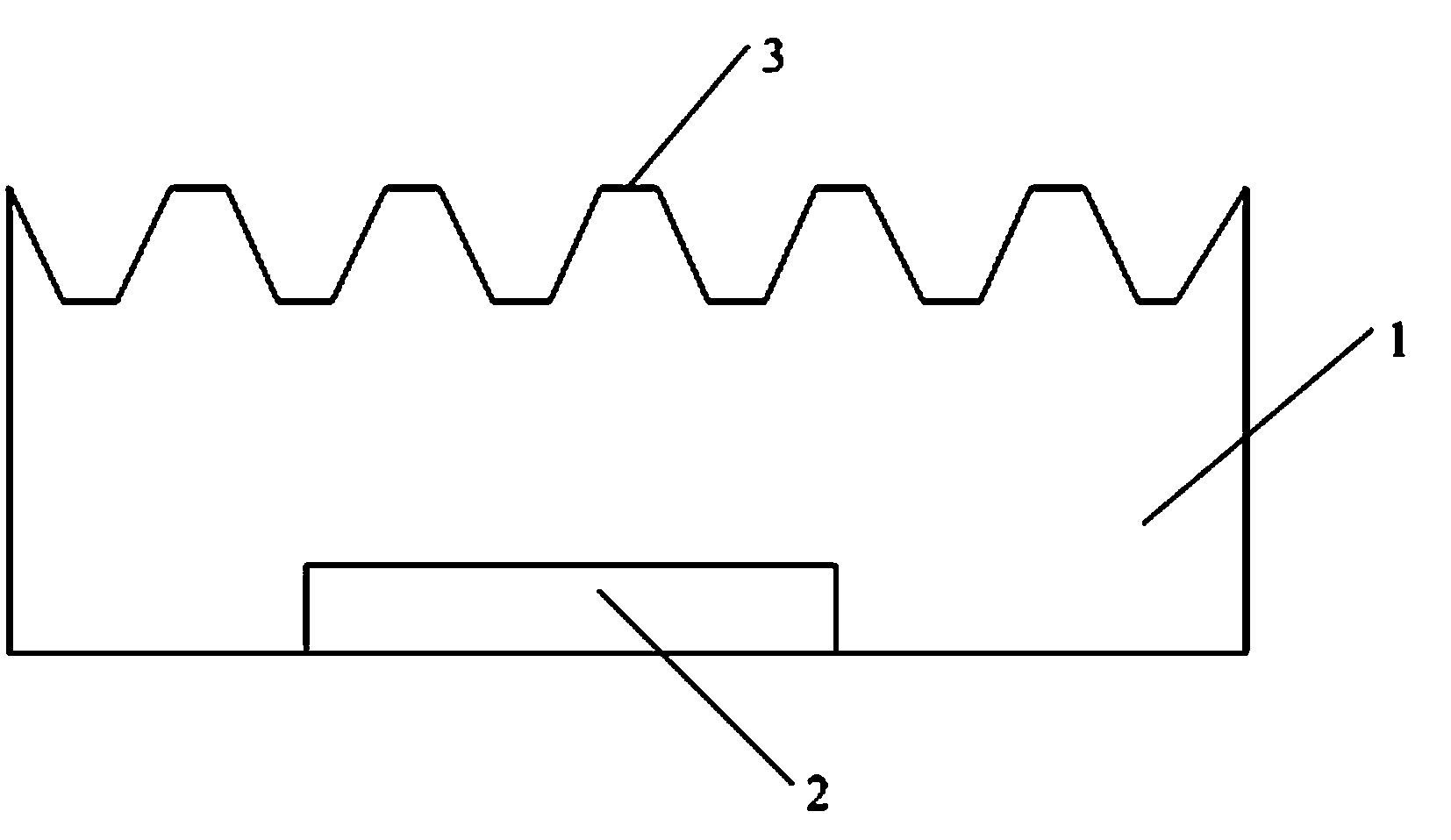

[0030] Such as figure 2 As shown, Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cross-section of the concave-convex structure 3 is trapezoidal.

Embodiment 3

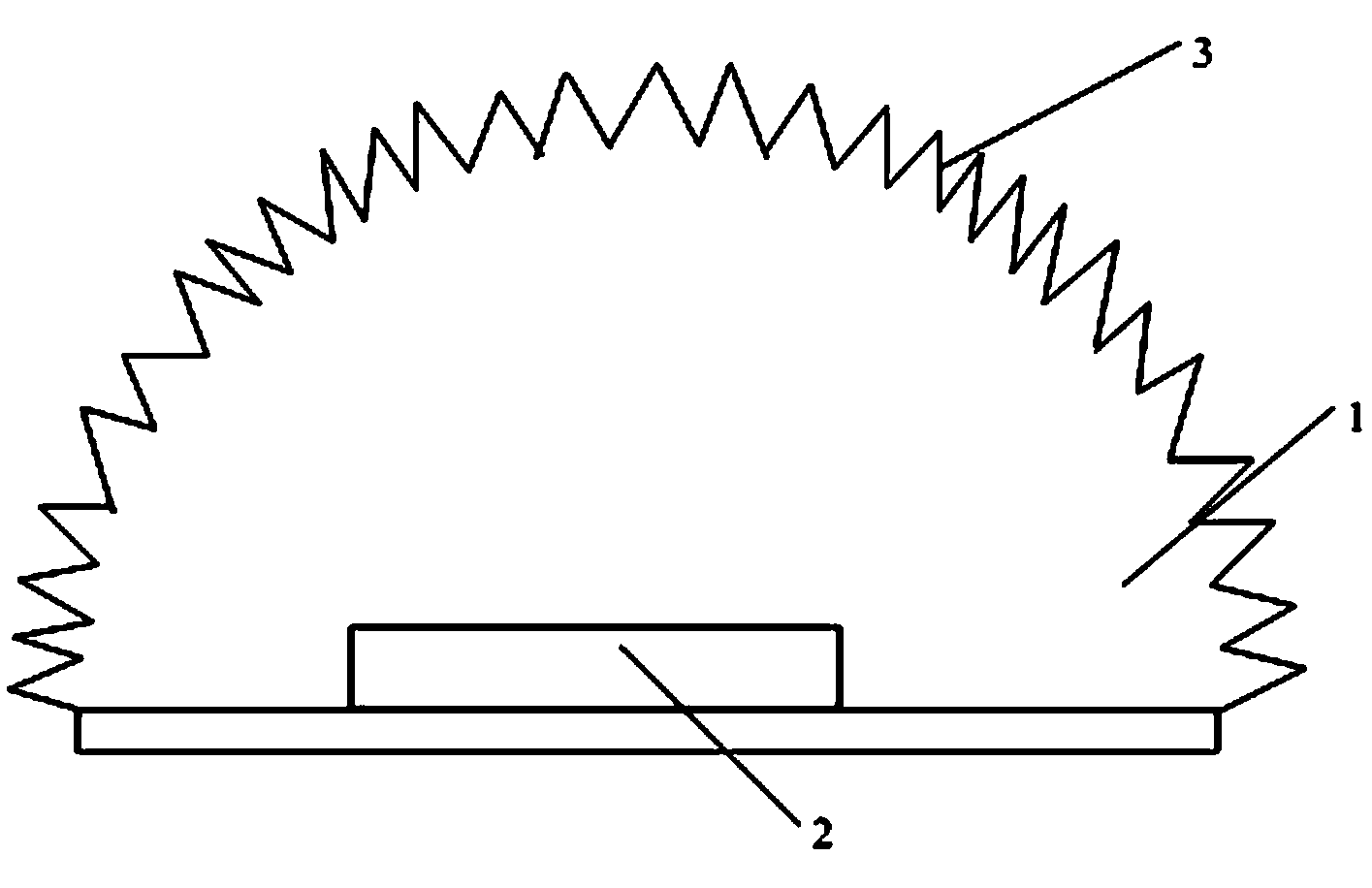

[0031] Such as image 3 , as shown, Embodiment 3: The difference between this embodiment and Embodiment 1 is that the surface of the LED package is protruding, and its cross-section is arc-shaped. The surface of such an LED package is roughened, and the requirements for the plastic film It has strong flexibility.

[0032] Such as Figure 4 As shown, a method for roughening the surface of an LED packaging structure, it comprises the following steps:

[0033] Step 1: Make a concave-convex structure on the plastic film. If the concave-convex structure on the plastic film is a regular geometric shape, it can be made with a photolithography mold, or compression molded with a compression mold. The concave-convex structure is a microstructure (must be optically A crystal structure that can only be observed with a microscope or an electron microscope), according to the size of the plastic film, and the depth and shape of the predetermined concave-convex structure, the distribution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com